Pneumatic sealing combined control valve

A combined control and pneumatic sealing technology, applied to valve details, valve devices, engine components, etc., can solve problems such as wear and valve seal failure, and achieve the effects of simplified structure, consistent abutment strength, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

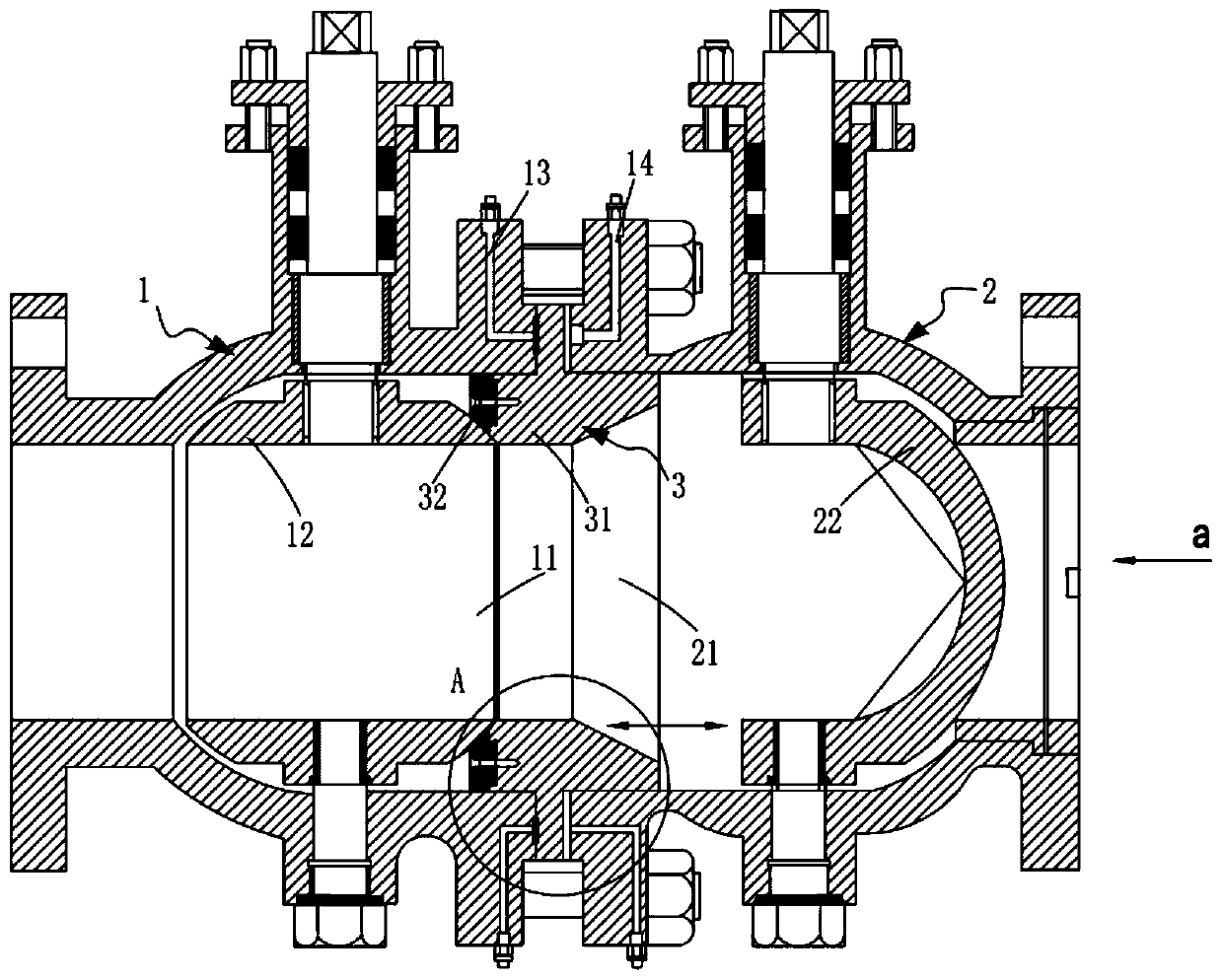

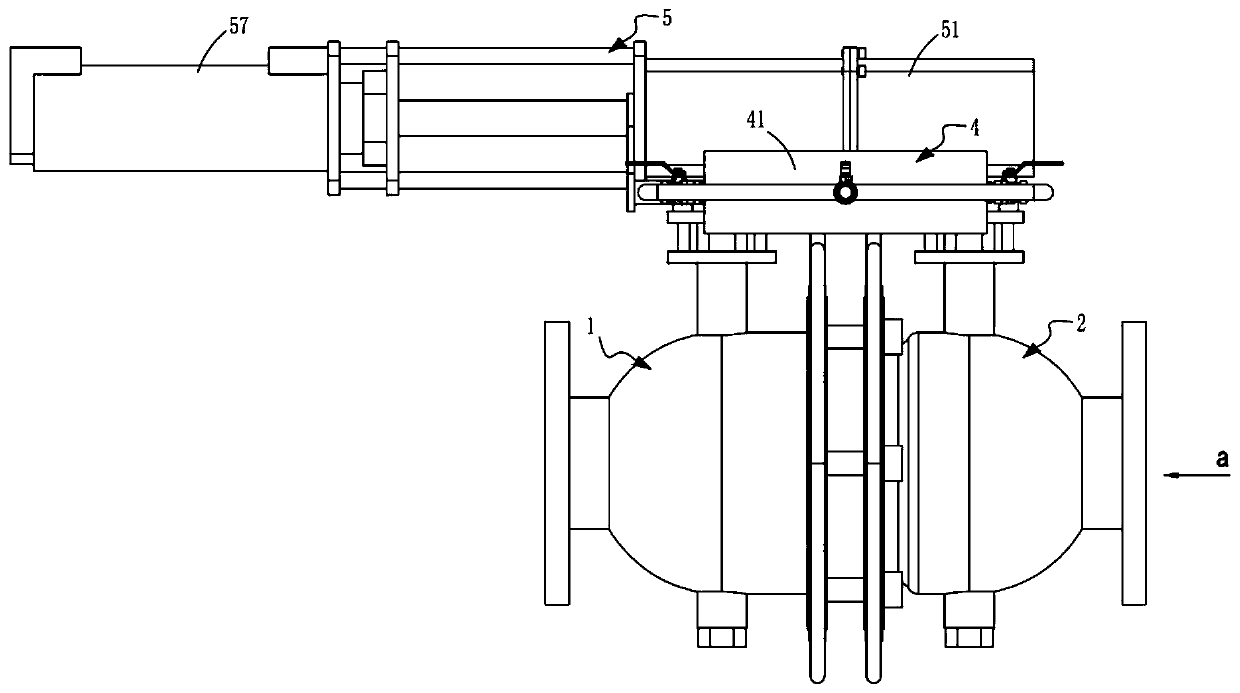

[0046] Such as Figure 1 to Figure 3 As shown, a pneumatic sealing combination control valve includes a sealing valve 1 and a material retaining valve 2, the feed port 11 of the sealing valve 1 communicates with the discharge port 21 of the material retaining valve 2, and the sealing valve 1 is provided with a spherical first valve core 12, and the said blocking valve 2 is provided with a partially spherical "V"-shaped notch-shaped second valve core 22, which also includes:

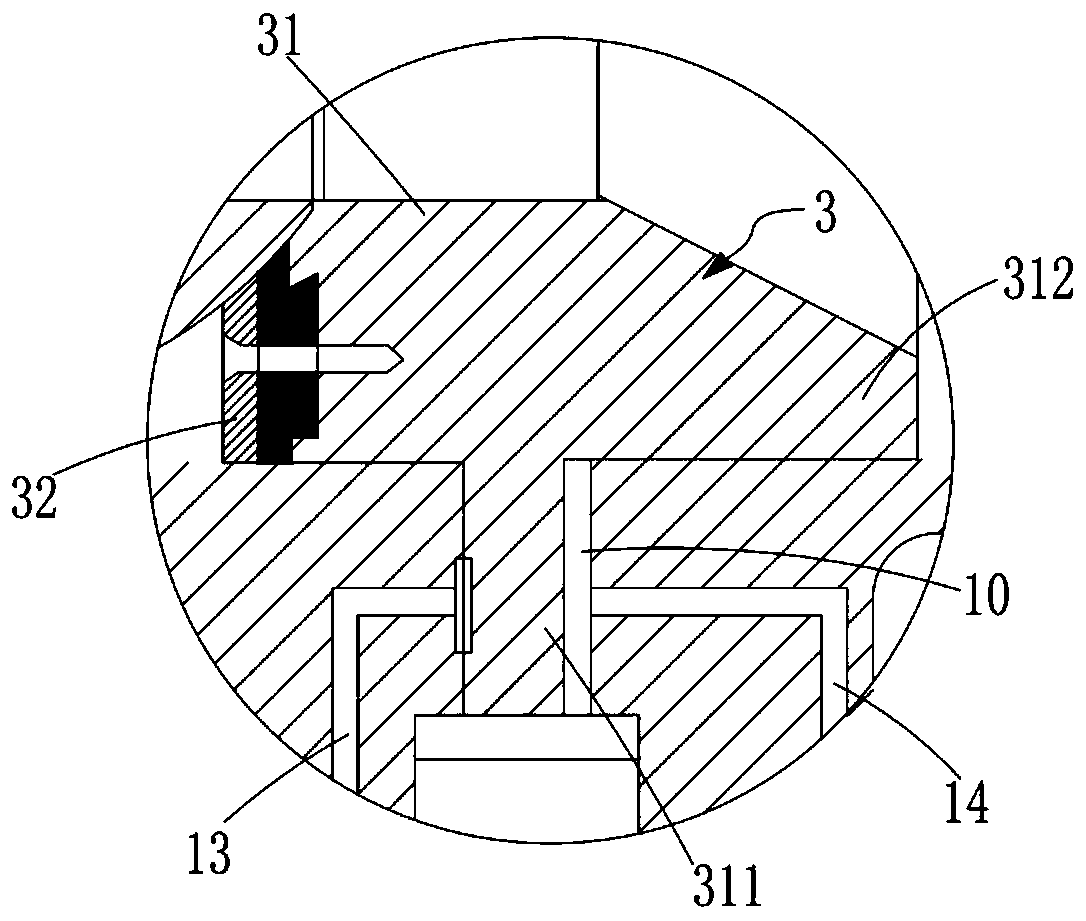

[0047] The floating sealing mechanism 3, the floating sealing mechanism 3 is arranged at the connection position between the sealing valve 1 and the material blocking valve 2, which includes a piston 31 that reciprocates along the medium flow direction a in the sealing valve 1 and is installed on The sealing valve seat 32 on the piston 31, the sealing valve seat 32 moves with the piston 31 whenever the piston 31 moves, and it abuts and seals against the first valve core 12;

[0048] Pneumatic mechanism 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com