A silk laying method for increasing the laying stroke of the concave cylindrical surface

A stroke and wire laying technology, which is applied in the field of wire laying to increase the laying stroke of the concave cylinder, can solve the problems of limited processing stroke, equipment limit, complex shape of wire laying, etc., so as to expand the laying area and increase the The effect of expanding the processing range and working margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0026] The present invention provides a method of laying silk to increase the laying stroke of a concave cylindrical surface, and laying silk on a curved surface includes the following steps:

[0027] Step 1, design the trajectory according to the shape of the surface

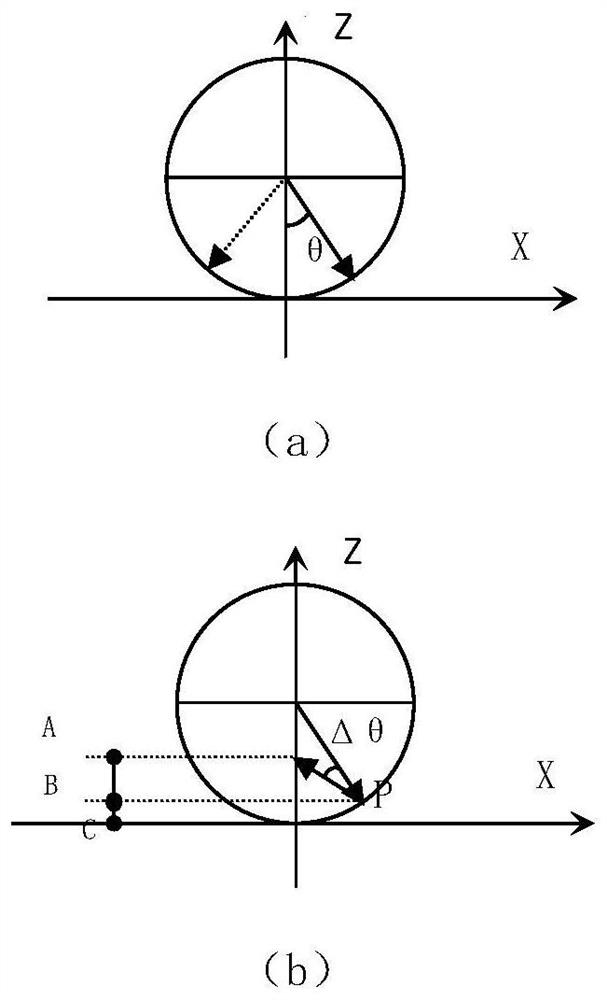

[0028] Step 2, convert the trajectory into mechanical language, and control the operation of the equipment. In this step, for the curved surface that needs to be laid, the inclined angle is used to press and lay the shape. The curved surfaces include but are not limited to the following types: semi-cylindrical concave curved surfaces, cylindrical surfaces, elliptical cylindrical surfaces, vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com