Hanging structure and hanging method of 3D printing sand core

A 3D printing and sand core technology, which is applied in the field of 3D printing sand core hanging structure, can solve the problem that the sand core lifting structure cannot be pre-embedded, and achieves the effects of convenient lifting, simple preparation, and safe and stable lifting process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail through the drawings and examples below. Through these descriptions, the features and advantages of the present invention will become more apparent.

[0019] According to the first aspect of the present invention, such as figure 1 and figure 2 As shown, the present invention provides a 3D printing sand core hanging method, the hanging method includes the following steps:

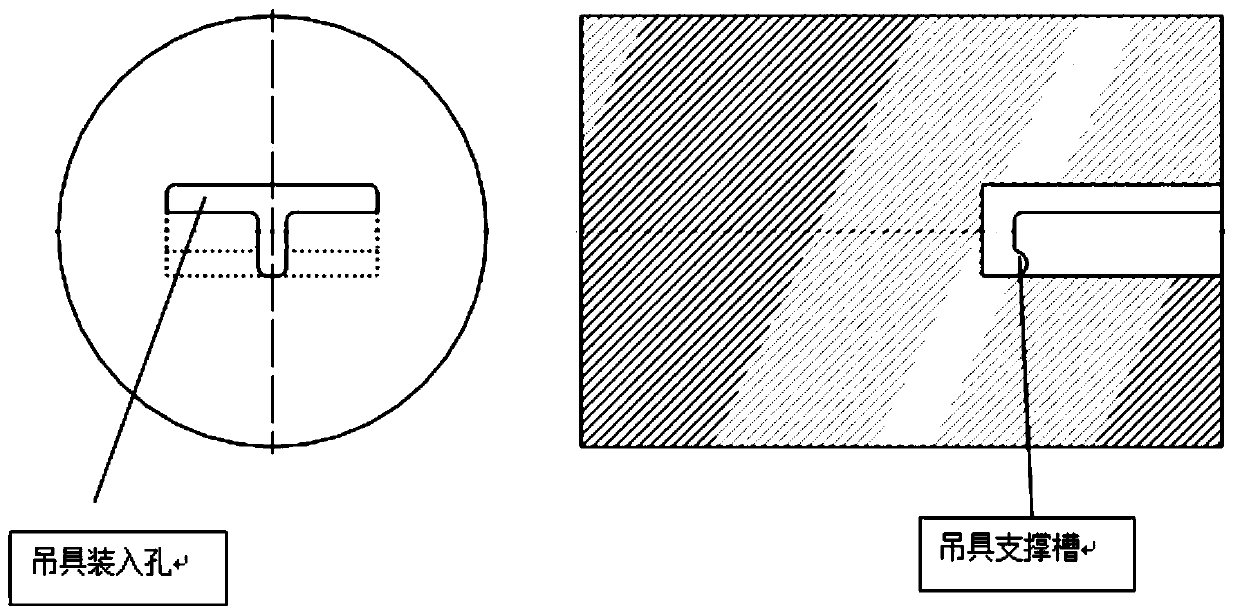

[0020] During the design process of the 3D printing sand core, a lifting hole slot is reserved inside the sand core, the lifting hole slot is located in the middle and upper part of the sand core and the opening of the lifting hole slot is located on the upper surface of the sand core;

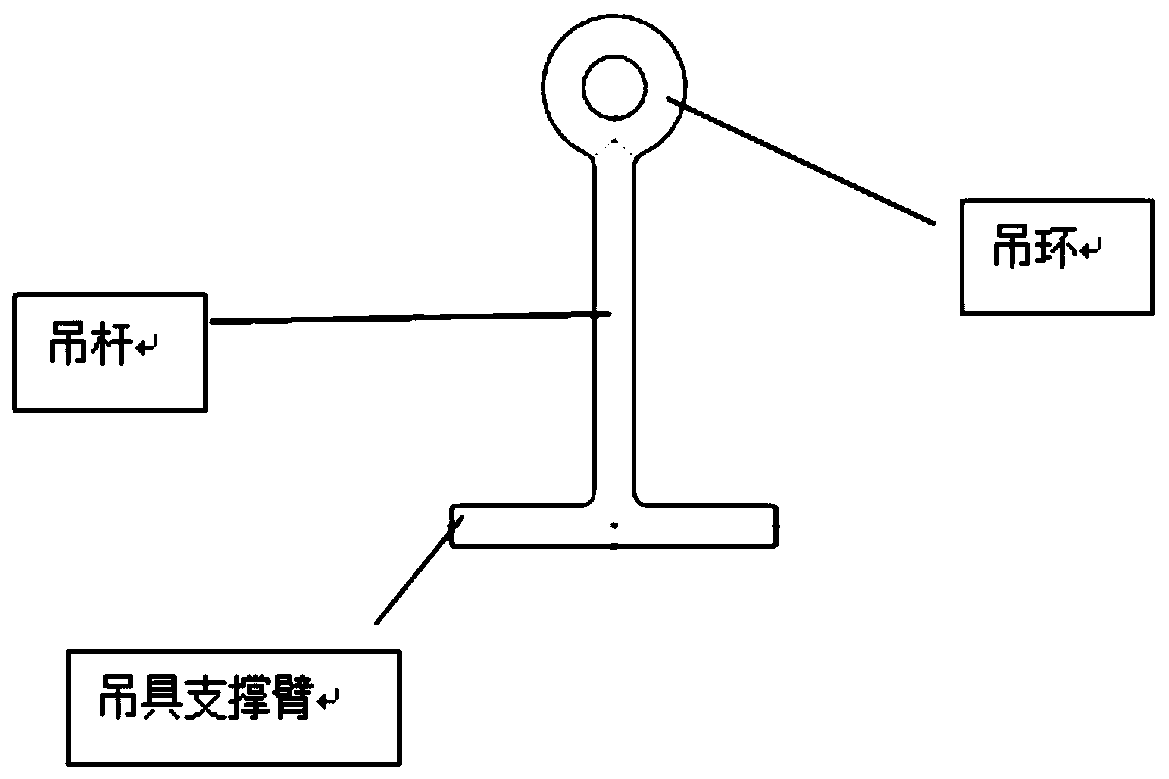

[0021] The hoisting hole slot is composed of a hoisting tool loading hole and a hoisting tool supporting slot. The hoisting tool loading hole extends into the sand core, and the hoisting tool supporting slot and the hoisting tool loading hole are out of posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com