A kind of porous carbon material based on melon rind and its preparation method and application

A porous carbon material and melon rind technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as difficulty in control and complex carbonization process, and achieve simplified carbonization process, wide application range, and high value. The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

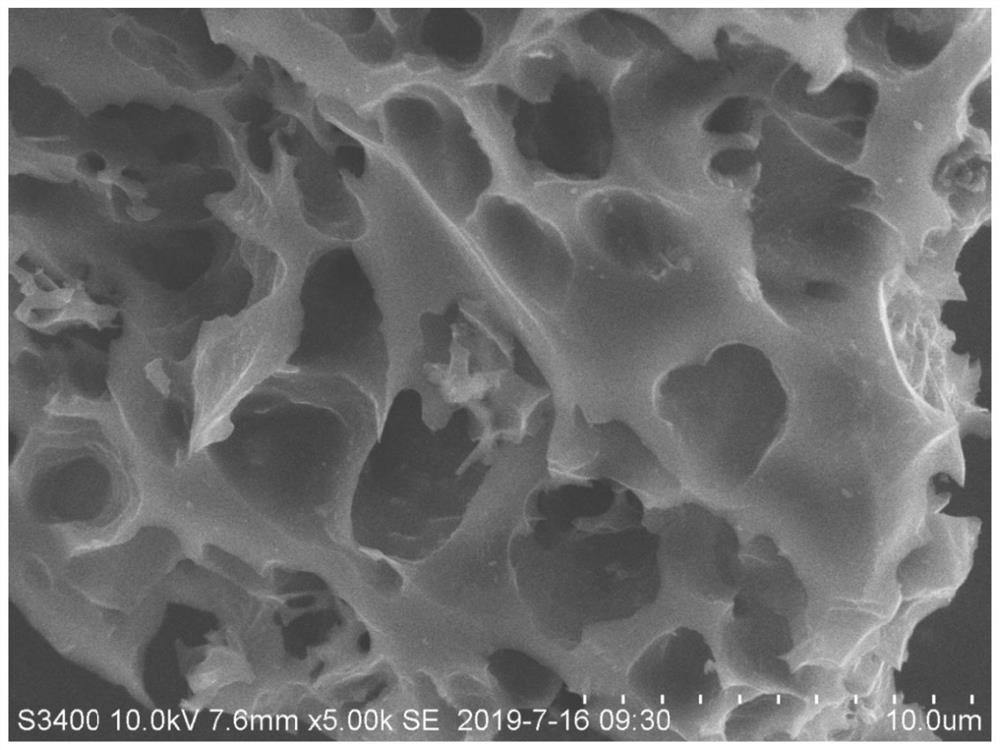

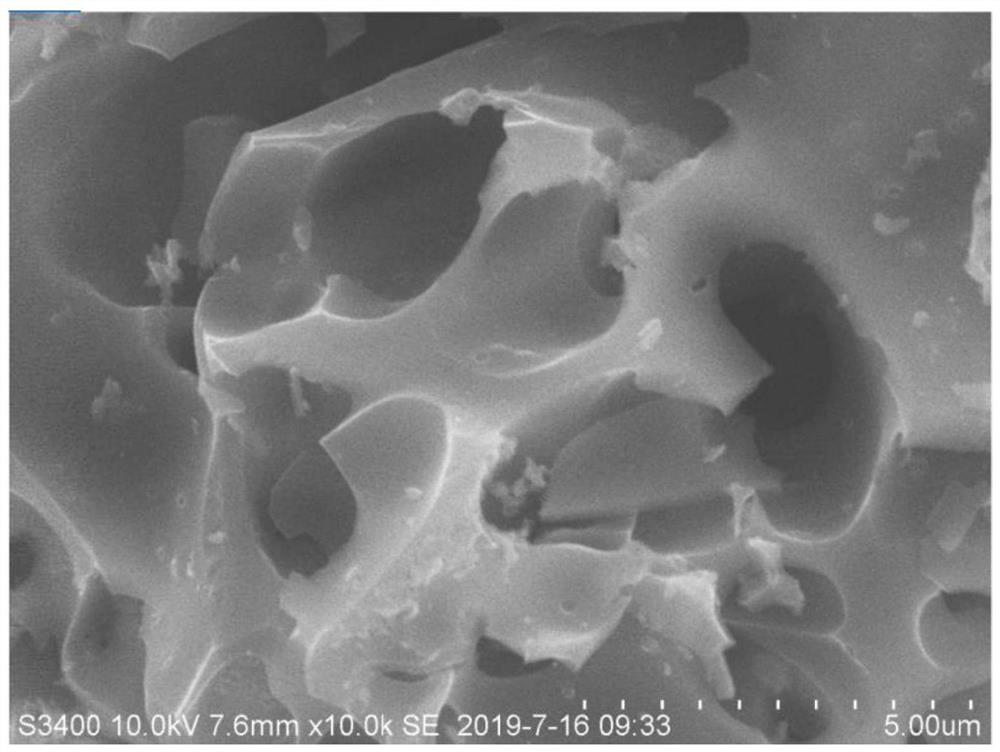

Image

Examples

Embodiment 1

[0030] A kind of preparation method based on the porous carbon material of watermelon rind, comprises the steps:

[0031] (1) Put 95 parts by weight of fresh watermelon rind, 3 parts by weight of ammonium bicarbonate and 2 parts by weight of urea into a corundum crucible, place the crucible in a vacuum sintering furnace, evacuate the air in the furnace, and slowly input nitrogen to make The air pressure in the furnace is maintained at 1 atmosphere;

[0032] (2) Under a nitrogen atmosphere, raise the temperature in the furnace to 36°C at a heating rate of 1°C / min, keep it for 20 minutes, then continue to raise the temperature in the furnace to 60°C at a heating rate of 0.5°C / min, and keep it for 30 minutes, Finally, continue to raise the temperature in the furnace to 110°C at a heating rate of 2°C / min and keep it warm for 20 minutes;

[0033] (3) Evacuate the gas in the furnace and input nitrogen to keep the air pressure in the furnace at 1 atmosphere;

[0034] (4) Under a ni...

Embodiment 2

[0039] A preparation method of a porous carbon material based on wax gourd rind, comprising the steps of:

[0040] (1) Put 90 parts by weight of fresh wax gourd skin, 5 parts by weight of ammonium bicarbonate and 5 parts by weight of urea into a corundum crucible, place the crucible in a vacuum sintering furnace, evacuate the air in the furnace, and slowly input nitrogen to make The air pressure in the furnace is maintained at 1 atmosphere;

[0041] (2) Under a nitrogen atmosphere, raise the temperature in the furnace to 36°C at a heating rate of 1°C / min, keep it for 20 minutes, then continue to raise the temperature in the furnace to 60°C at a heating rate of 0.5°C / min, and keep it for 30 minutes, Finally, continue to raise the temperature in the furnace to 110°C at a heating rate of 2°C / min and keep it warm for 20 minutes;

[0042] (3) Evacuate the gas in the furnace and input nitrogen to keep the air pressure in the furnace at 1 atmosphere;

[0043](4) Under a nitrogen at...

Embodiment 3

[0048] A preparation method of a porous carbon material based on luffa rind, comprising the steps of:

[0049] (1) Put the fresh loofah rind of 85 parts by weight, the ammonium bicarbonate of 7 parts by weight and the urea of 8 parts by weight into the corundum crucible, place the crucible in the vacuum sintering furnace, evacuate the air in the furnace, and slowly input nitrogen to make The air pressure in the furnace is maintained at 1 atmosphere;

[0050] (2) Under a nitrogen atmosphere, raise the temperature in the furnace to 36°C at a heating rate of 1°C / min, keep it for 20 minutes, then continue to raise the temperature in the furnace to 60°C at a heating rate of 0.5°C / min, and keep it for 30 minutes, Finally, continue to raise the temperature in the furnace to 110°C at a heating rate of 2°C / min and keep it warm for 20 minutes;

[0051] (3) Evacuate the gas in the furnace and input nitrogen to keep the air pressure in the furnace at 1 atmosphere;

[0052] (4) Under a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com