Monotectic alloy material and preparing method thereof

A technology of monotectic alloy and base material, applied in the field of monotectic alloy material and its preparation, can solve the problems of difficulty in obtaining monotectic alloy, alloy segregation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

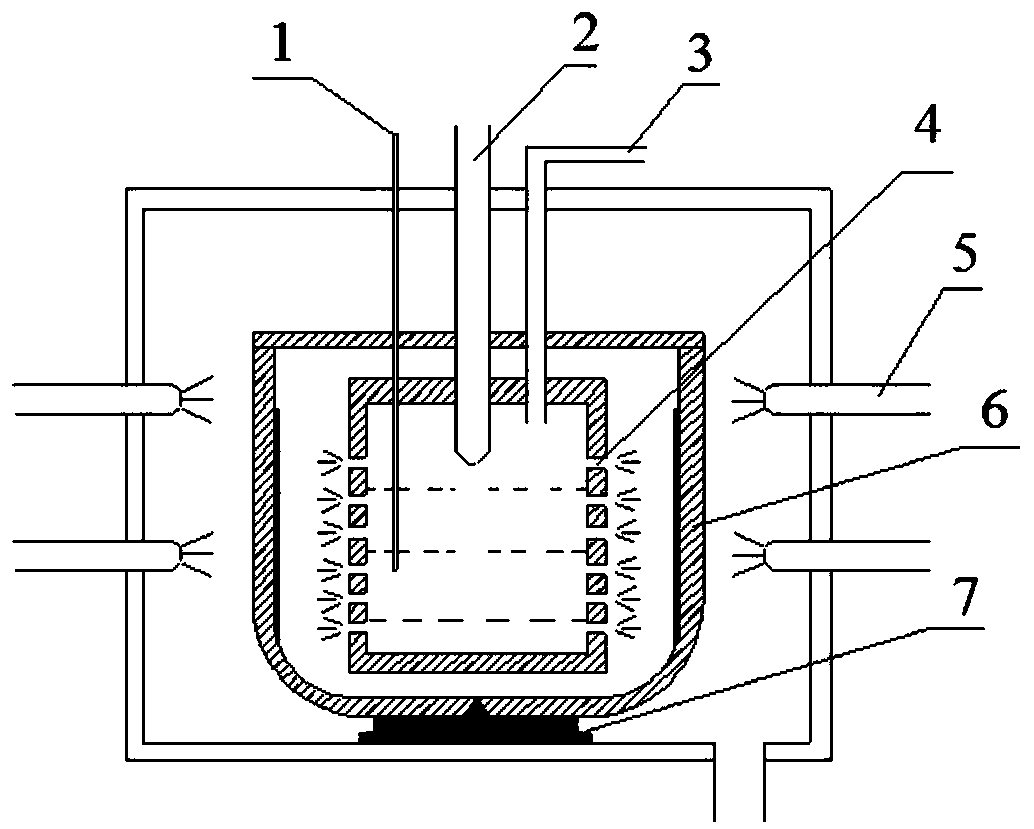

[0024] The invention provides a method for preparing a monotectic alloy material, comprising the following steps:

[0025] Melting the monotectic alloy raw material in a crucible to obtain a smelting solution;

[0026] Spraying the smelting liquid onto the substrate through the micropores of the crucible under the action of an inert gas to obtain a monotectic alloy material;

[0027] The pressure of the inert gas is ≥7MPa; the temperature of the substrate is 20-30°C.

[0028] The invention melts the monotectic alloy raw material in a crucible to obtain a smelting liquid.

[0029] The present invention does not specifically limit the type of the monotectic alloy raw material, and those skilled in the art can select according to the monotectic alloy raw material to be prepared; the present invention does not specifically limit the melting temperature and time, according to the The selected monotectic alloy raw material can be set. In a specific embodiment of the present inven...

Embodiment 1

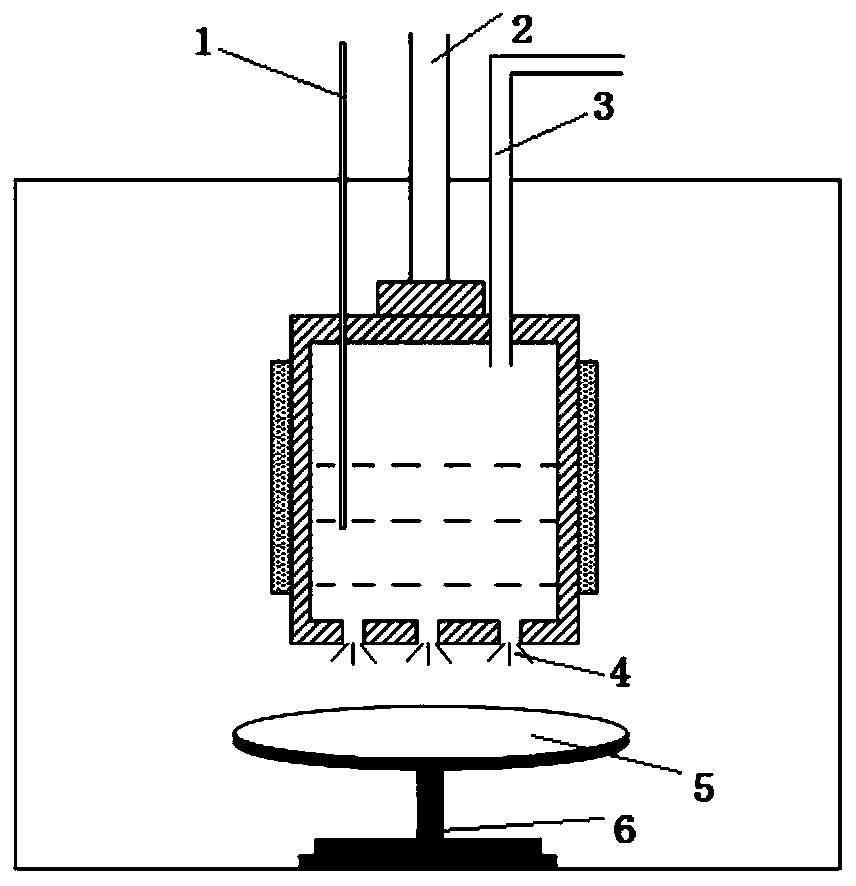

[0039] use figure 2 The equipment prepares monotectic alloy materials on the surface of iron discs:

[0040] Put the Al-Bi monotectic alloy raw material with a mass ratio of 9:1 on the Si 3 N 4 In the crucible, the temperature was raised to 1000°C through the electromagnetic induction melting device, and the temperature was kept for 10 minutes to obtain the melting liquid;

[0041] Inert gas with a pressure of 10 MPa is poured into the crucible, so that the melting liquid in the crucible is sprayed from the micropores (aperture 1.5 mm) on the bottom surface of the crucible to the rotating iron disc (temperature is 20 ° C), so that The linear speed of the iron disc is 5m / s, and it is sprayed for 5 minutes to obtain a monotectic alloy material.

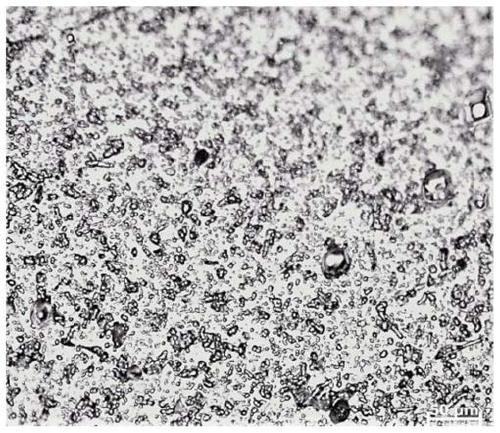

[0042] image 3 For the metallographic microstructure photo of the monotectic alloy material obtained in this embodiment, from image 3 It can be seen that the monotectic alloy grains are dispersed and the solidified structure is ...

Embodiment 2

[0044] use figure 2 The equipment shown prepares monotectic alloy material on the surface of an iron disc:

[0045] Put the Al-Pb monotectic alloy raw material with a mass ratio of 9:1 on the Si 3 N 4 In the crucible, the temperature was raised to 1000°C through the electromagnetic induction melting device, and the temperature was kept for 10 minutes to obtain the melting liquid;

[0046] Pour into the crucible an inert gas with a pressure of 20 MPa, so that the molten liquid in the crucible is sprayed from the micropores (aperture 1.0 mm) on the bottom surface of the crucible to the rotating iron disk (temperature is 20 ° C), so that The linear speed of the iron disc is 10m / s, spray for 10min, and obtain the monotectic alloy material.

[0047] Figure 4 For the metallographic microstructure photo of the monotectic alloy material obtained in this embodiment, from Figure 4 It can be seen that the distribution of black Pb phase particles in the Al matrix is dense and un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com