Acoustic resistance material testing device

A testing device and technology for acoustic resistance materials, which are applied in measurement devices, analysis materials, and material analysis using sonic/ultrasonic/infrasonic waves, etc., can solve the problems affecting the efficiency of testing, the complex operation of the testing device for acoustic resistance materials, and the low testing accuracy. and other problems to achieve the effect of improving test efficiency, facilitating re-testing, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

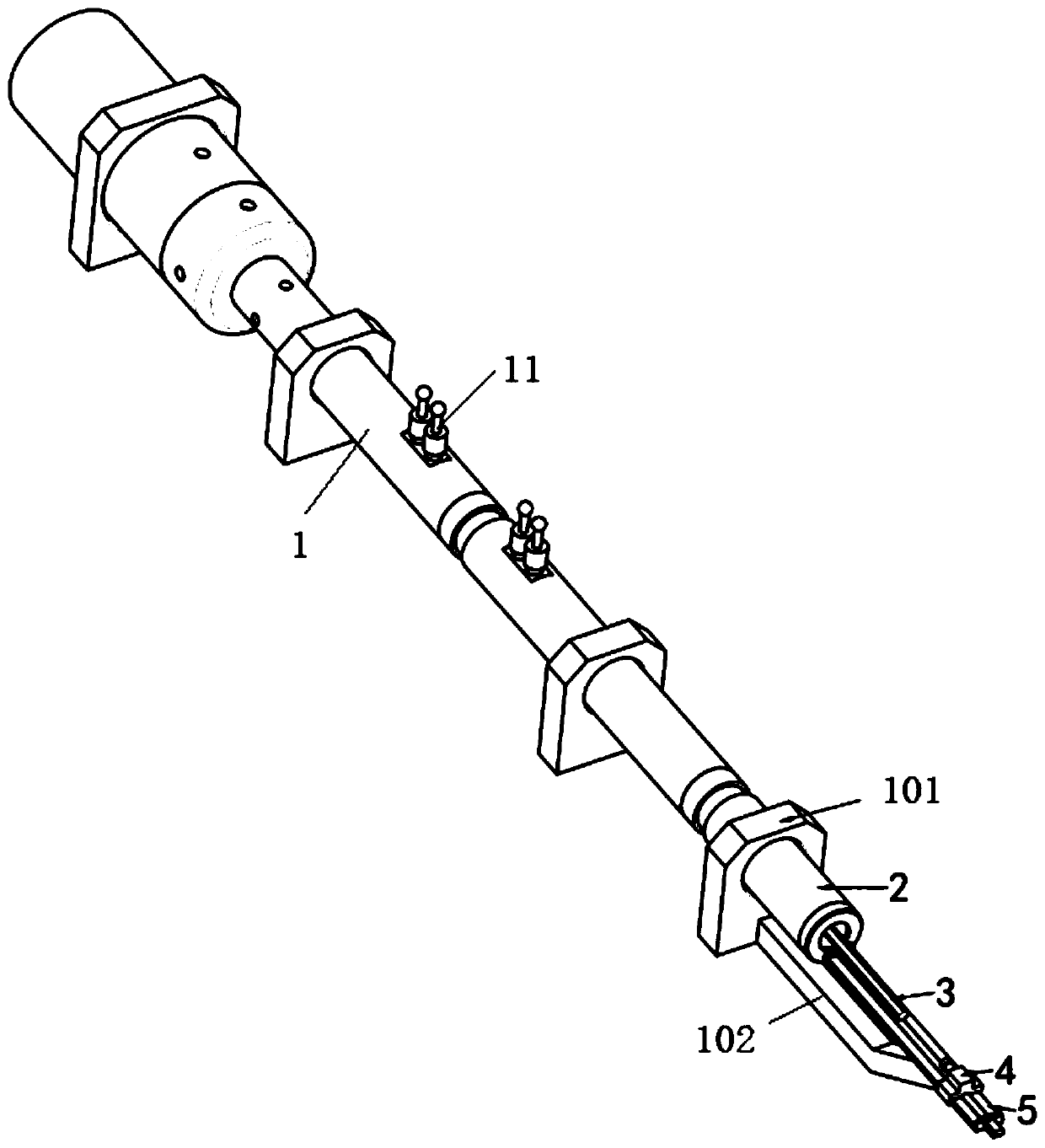

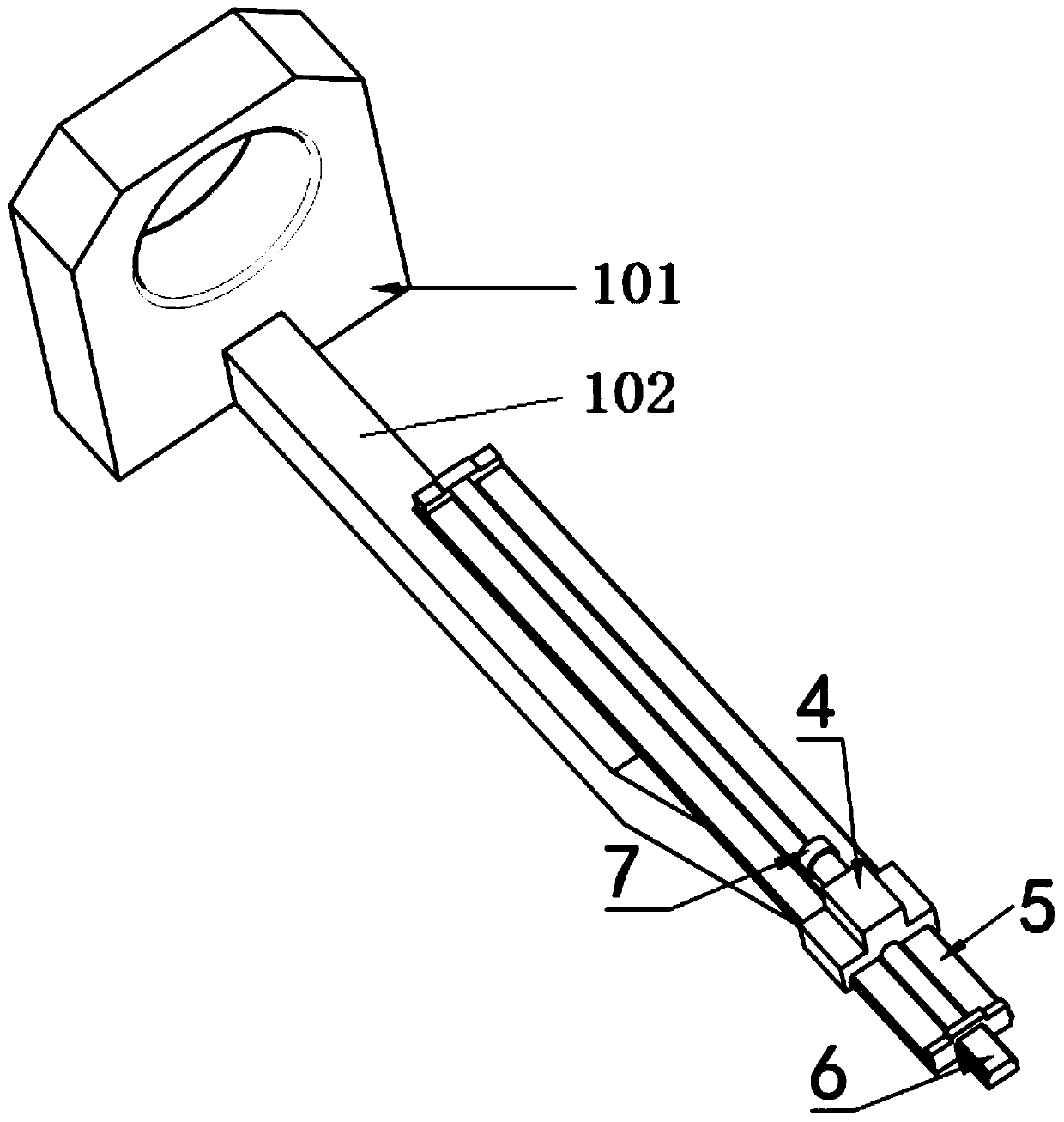

[0046] Such as Figures 1 to 4 And shown in 9, a kind of acoustic resistance material testing device, comprises:

[0047] A plurality of sound resistance tubes, each sound resistance tube can be detachably connected, the sound resistance tube includes the first end sound resistance tube 1 and the end sound resistance tube 2, and the first end sound resistance tube 1 and the end sound resistance tube 2 are equipped with pickups 11;

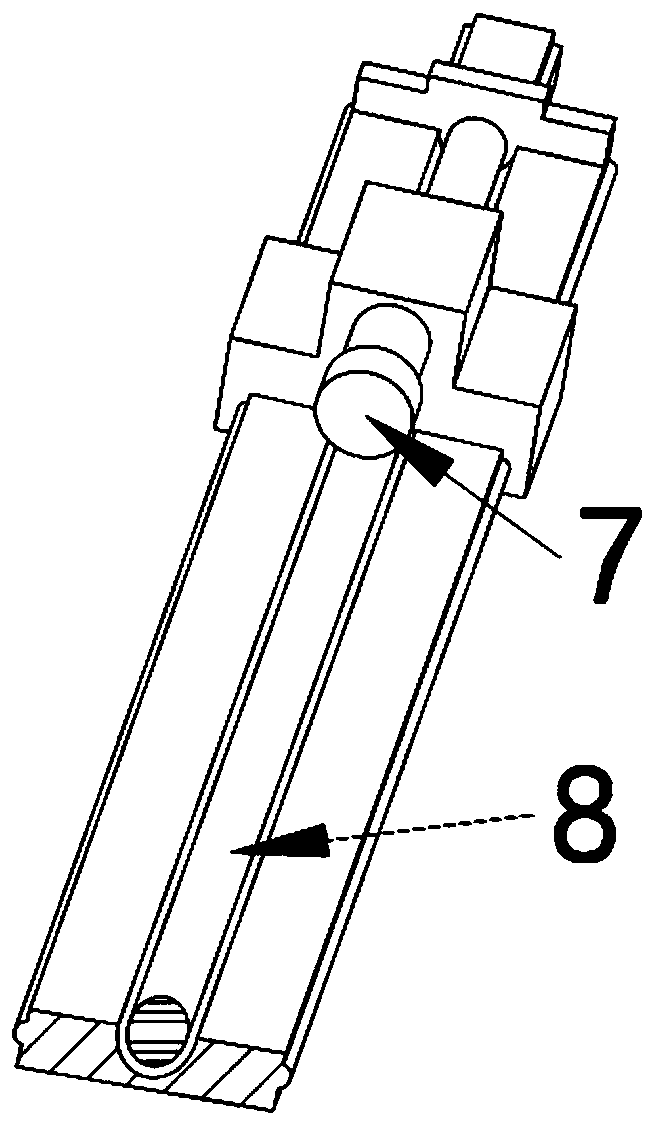

[0048] A sliding pair, the sliding pair includes a slider 4 and a slide rail 5, and the slide rail 5 is installed on the supporting device through a mounting plate 9 and bolts;

[0049] Feeding device, the feeding device is installed on the slide rail 5 and is used to drive the slider 4 to slide along the slide rail 5;

[0050] The sound-absorbing cotton adjustment slide bar 3, the sound-absorbing cotton adjustment slide bar 2 is installed on the supporting device and located on one side of the slide rail 5; the sound-absorbing cotton adjustment ...

Embodiment 2

[0062] Such as Figures 5 to 9 Shown, a kind of acoustic resistance material testing device comprises:

[0063] A plurality of sound resistance tubes, each sound resistance tube can be detachably connected, the sound resistance tube includes the first end sound resistance tube 1 and the end sound resistance tube 2, and the first end sound resistance tube 1 and the end sound resistance tube 2 are equipped with pickups 11;

[0064] A sliding pair, the sliding pair includes a slider 4 and a slide rail 5, and the slide rail 5 is installed on the supporting device through a mounting plate 9 and bolts;

[0065] Feeding device, the feeding device is installed on the slide rail 5 and is used to drive the slider 4 to slide along the slide rail 5;

[0066] The sound-absorbing cotton adjustment slide bar 3, the sound-absorbing cotton adjustment slide bar 3 is installed on the supporting device and located on one side of the slide rail 5; the sound-absorbing cotton adjustment slide bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com