3D printing service system supporting online processing

A 3D printing and service system technology, applied in the field of 3D printing manufacturing, can solve the problems of high technical threshold, limited number of models, high price, etc., to improve service capabilities and service efficiency, meet individual needs, and reduce high technical thresholds Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

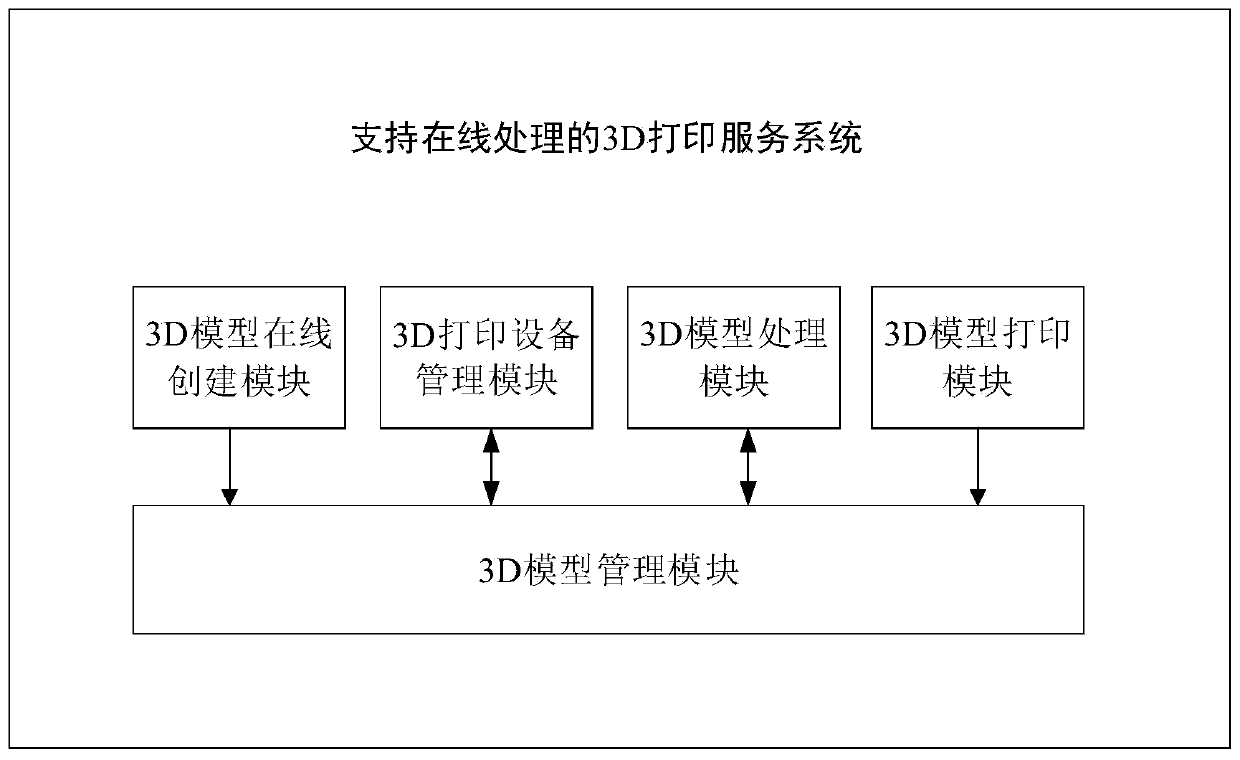

[0029] refer to figure 1 , the 3D printing service system supporting online processing provided by the embodiment of the present invention includes a 3D model management module, a 3D printing device management module, a 3D model online creation module, a 3D model processing module and a 3D model printing module, wherein:

[0030] The 3D model management module is used to classify and store each 3D model according to the type of the 3D model.

[0031] As a specific embodiment, the 3D models can be classified into character models, architectural models, toy models, lamp models, etc. according to their types.

[0032] The 3D printing device management module is used to classify and manage each 3D printing device according to connecting each 3D printing device to the 3D printing service system.

[0033] The 3D model online creation module i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com