High-performance heat-dissipation waterproof and dustproof electrical cabinet

A waterproof, dustproof, high-performance technology, applied in the field of electrical cabinets, can solve the problems of poor flexibility, low heat dissipation efficiency, rain or dust ingress, etc., to reduce the difficulty of maintenance work, prolong the service life, and improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings, but the required protection scope is not limited to the description;

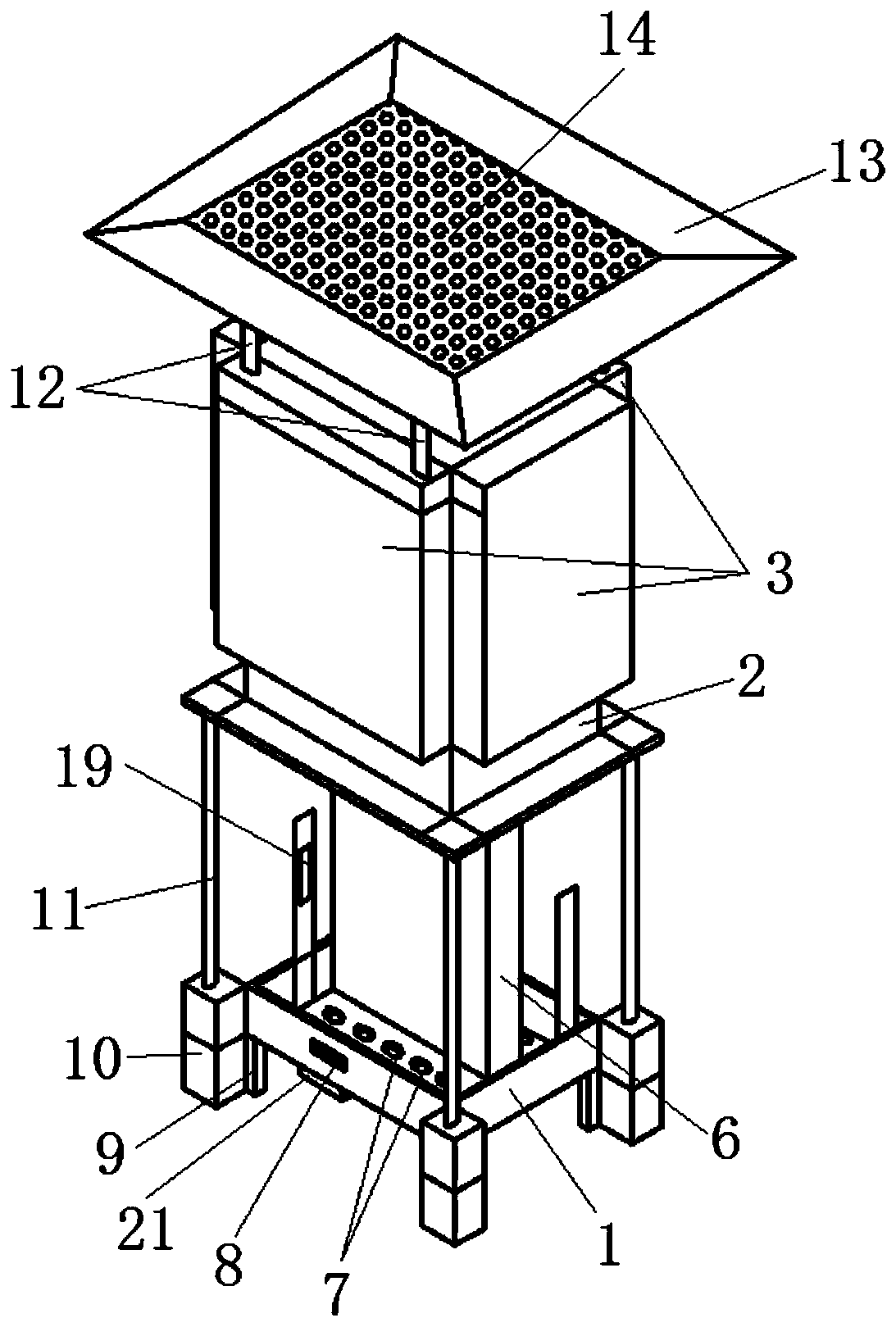

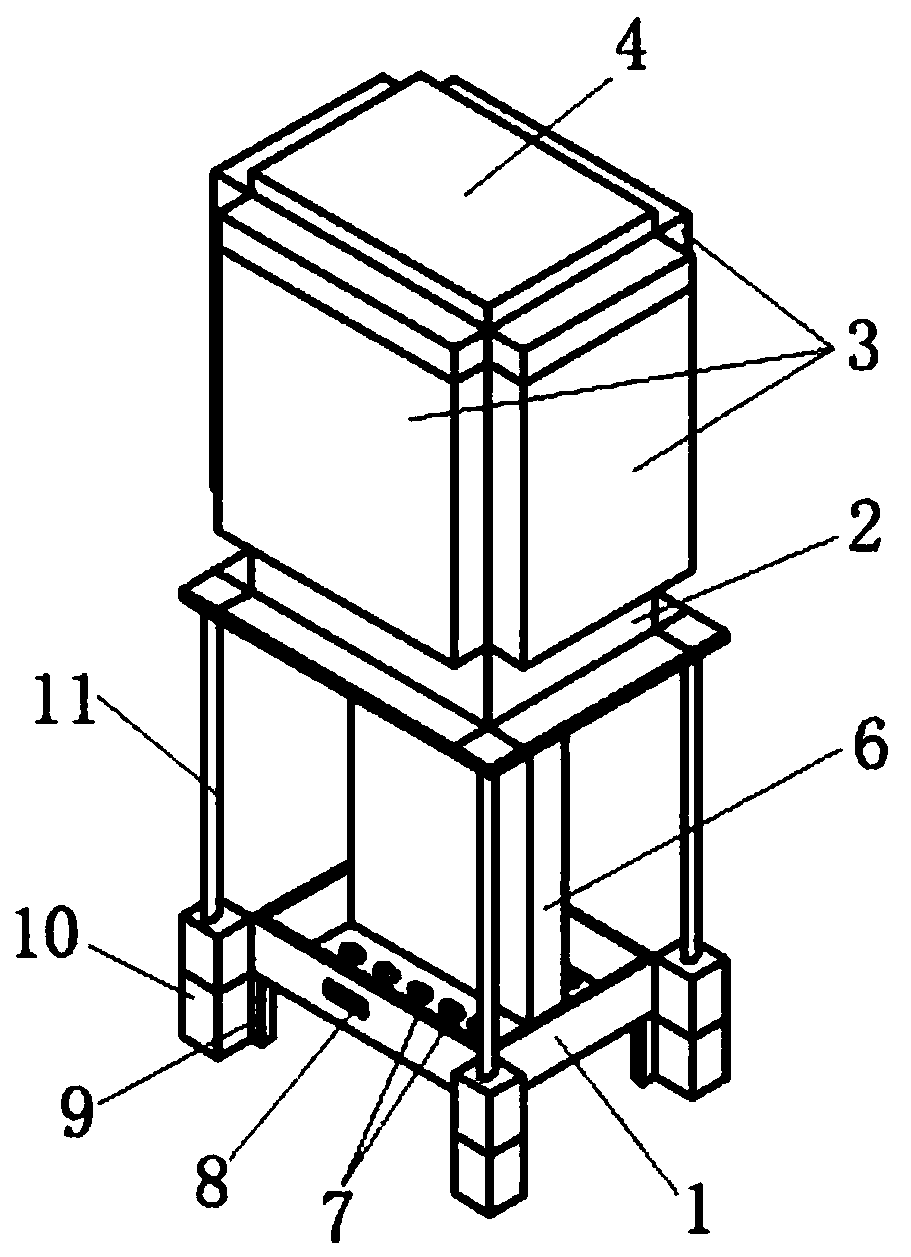

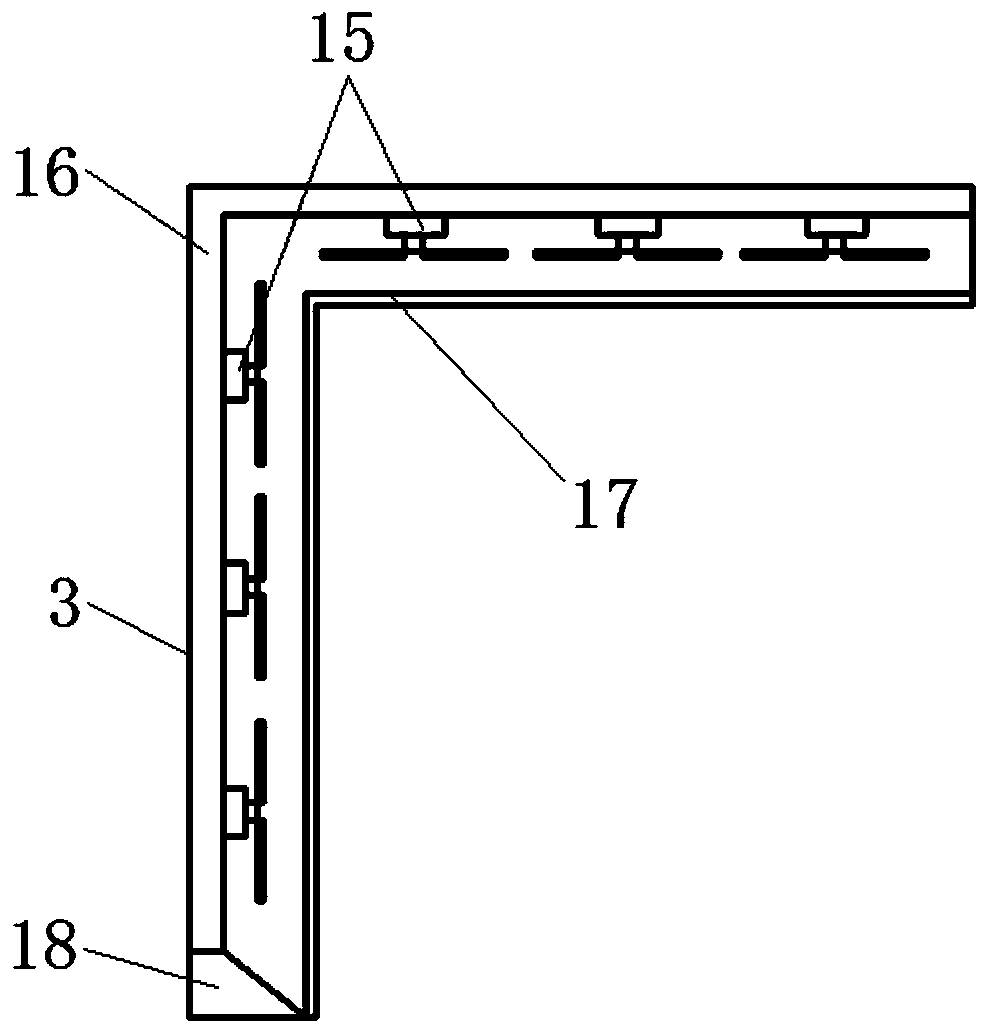

[0019] The invention provides a high-performance heat dissipation, waterproof and dustproof electrical cabinet, such as figure 1 , figure 2 with image 3 As shown, it includes a cabinet body 1, a hydraulic cylinder 11 is installed on the cabinet body 1, an outer cover 2 is fixedly connected to the piston rod of the hydraulic cylinder 11, and a cooling bellows 3 is installed around the outer cover 2, and several cooling fans are installed inside the cooling bellows 3 15. The top of the outer cover 2 is also fixedly connected with a rainshield 13 through the push rod 12, the top surface of the rainshield 13 is equipped with a solar panel 14, and the battery 4 is also installed inside the outer cover 2, and the solar panel 14, the battery 4 and the cooling fan 15 are sequentiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com