Waterproof and breathable structure of starter

A waterproof, breathable and starter technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of increasing the overall cost, low applicability, increasing structural complexity, etc., to ensure stable operation, convenient installation, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

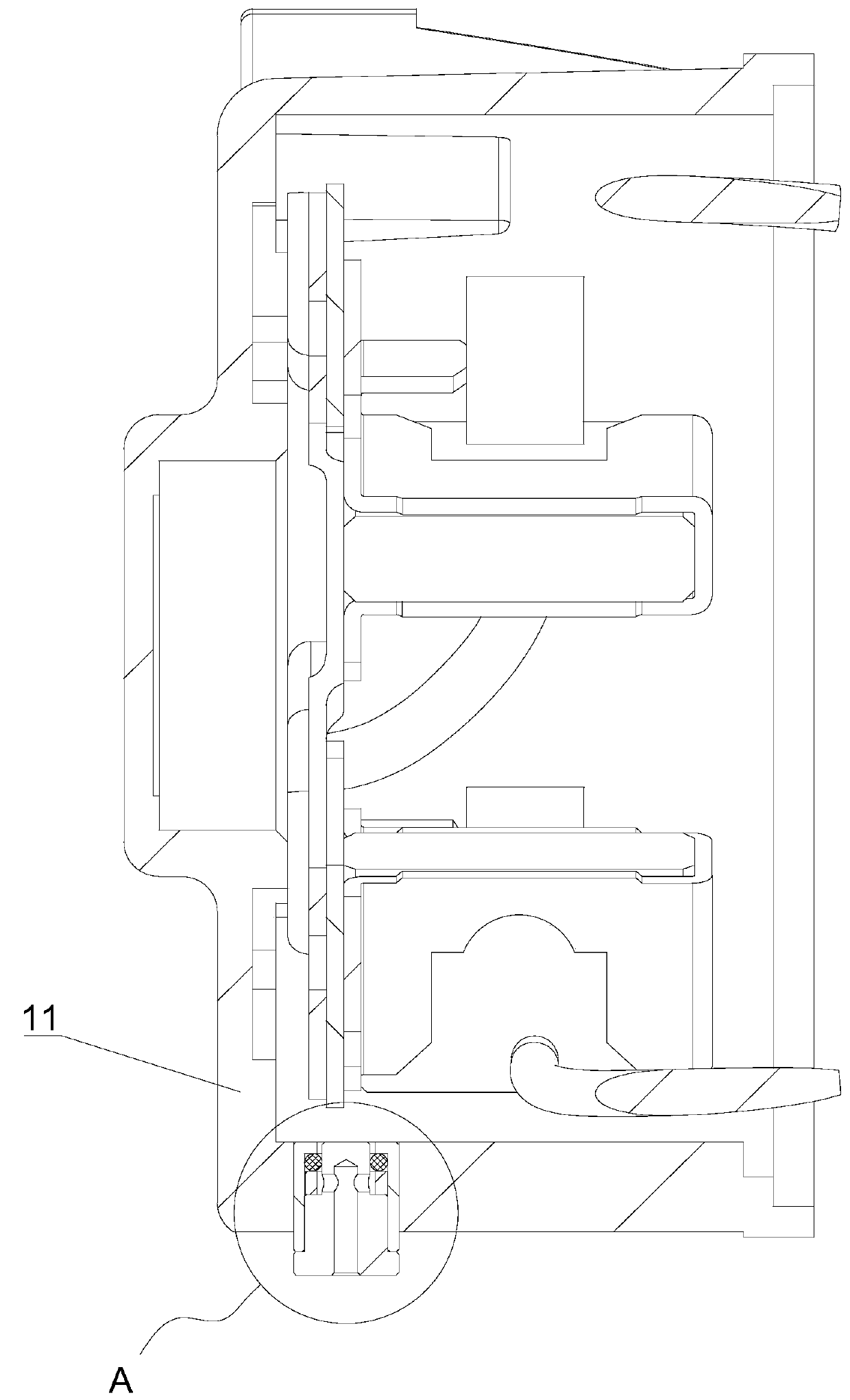

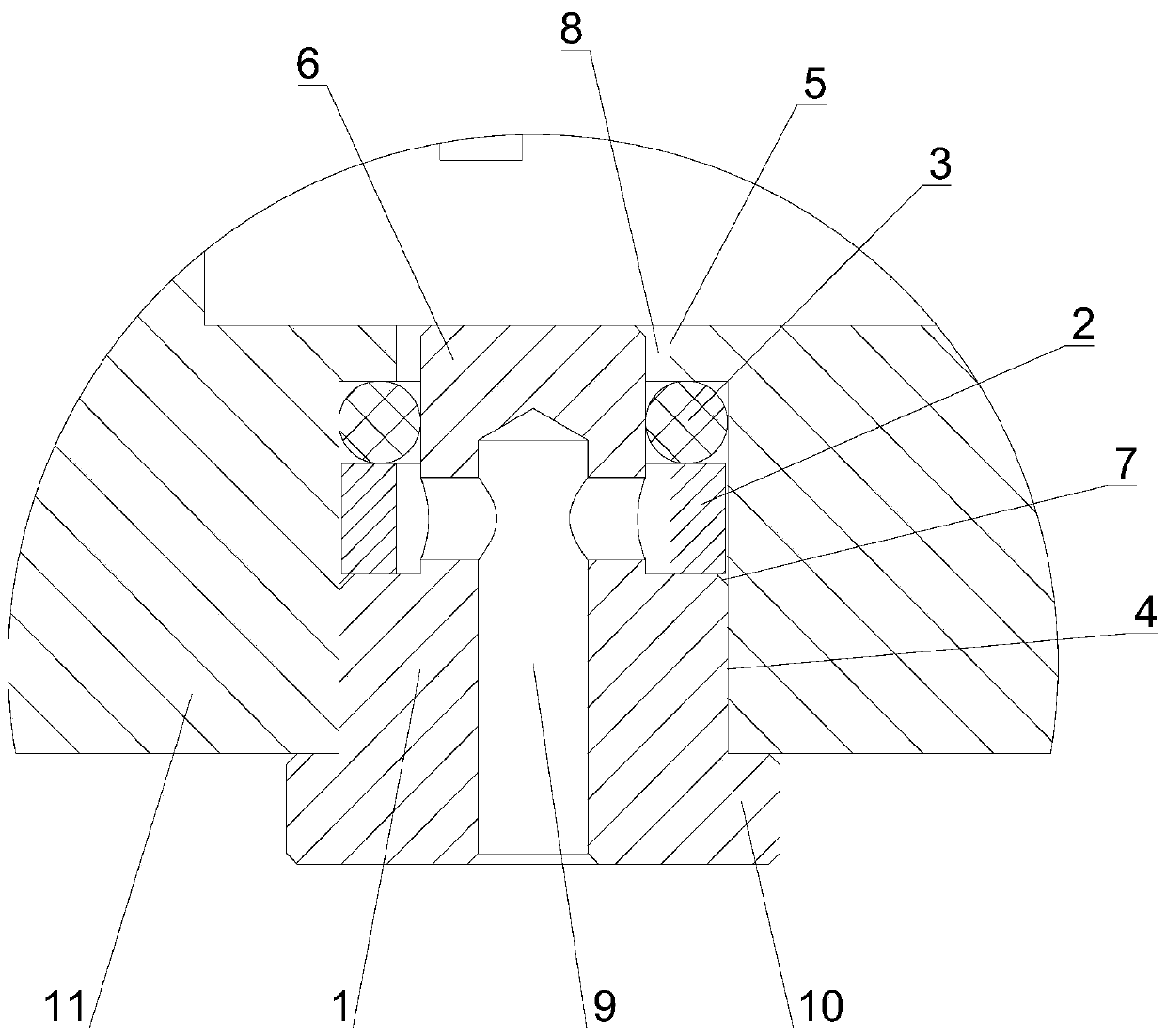

[0020] see figure 1 and 2 As shown, this embodiment provides a starter waterproof and breathable structure, which is arranged on the starter casing and can be installed at any suitable position on the starter casing as required. In this embodiment, the waterproof seal is set on the starter rear cover structure as an example.

[0021] The waterproof and breathable structure includes a breathable seat 1 , a bush 2 and a rubber sealing ring 3 .

[0022] The rear cover shell 11 is provided with an installation cavity 4 extending inward from the outer wall, and a through hole 5 is provided on the end wall of the installation cavity 4 to communicate the inner cavity with the outside.

[0023] The air-permeable seat 1 includes a main body and a plug 6. The plug 6 is arranged at the front end of the main body and forms a limit step 7. The main body is sealed and assembled with the installation cavity 4. Specifically, the main body and the installation cavity 4 are fitted through thr...

Embodiment 2

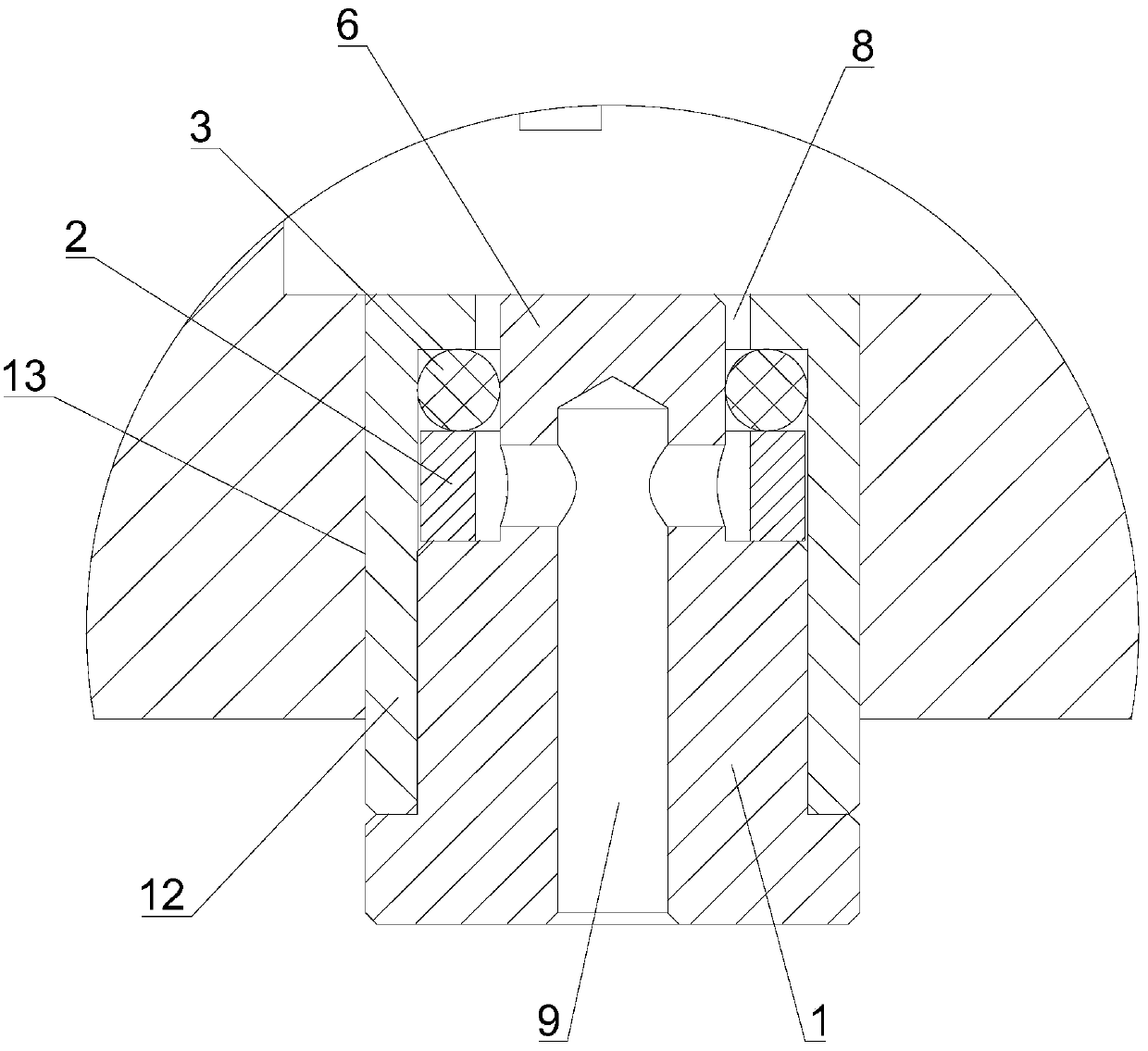

[0028] see image 3 As shown, this embodiment provides a starter waterproof and breathable structure. Under the inspiration of Embodiment 1, the waterproof and breathable structure also includes a mounting seat 12. In order to reduce the processing difficulty of the starter shell, only the Open the assembly hole 13 at the required position, form the installation cavity 4 on the installation seat 12, and then set the breathable seat 1, the bushing 2 and the rubber sealing ring 3, and finally fit the thread or interference fit between the installation seat 12 and the assembly hole 13 , to ensure tightness.

[0029] In summary, the waterproof and breathable structure of the starter cooperates with the breather seat through the sealing ring, and utilizes the principle of elastic deformation of the rubber body to realize the functions of liquid barrier and gas passage in the breather channel. The structure is simple, the cost is low, and the setting is convenient. It can be install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com