Multi-phase power supply for stepdown system

A power supply step-down, multi-phase technology, applied in electrical components, circuit devices, high-efficiency power electronic conversion, etc., to achieve the effect of improving safety and voltage conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

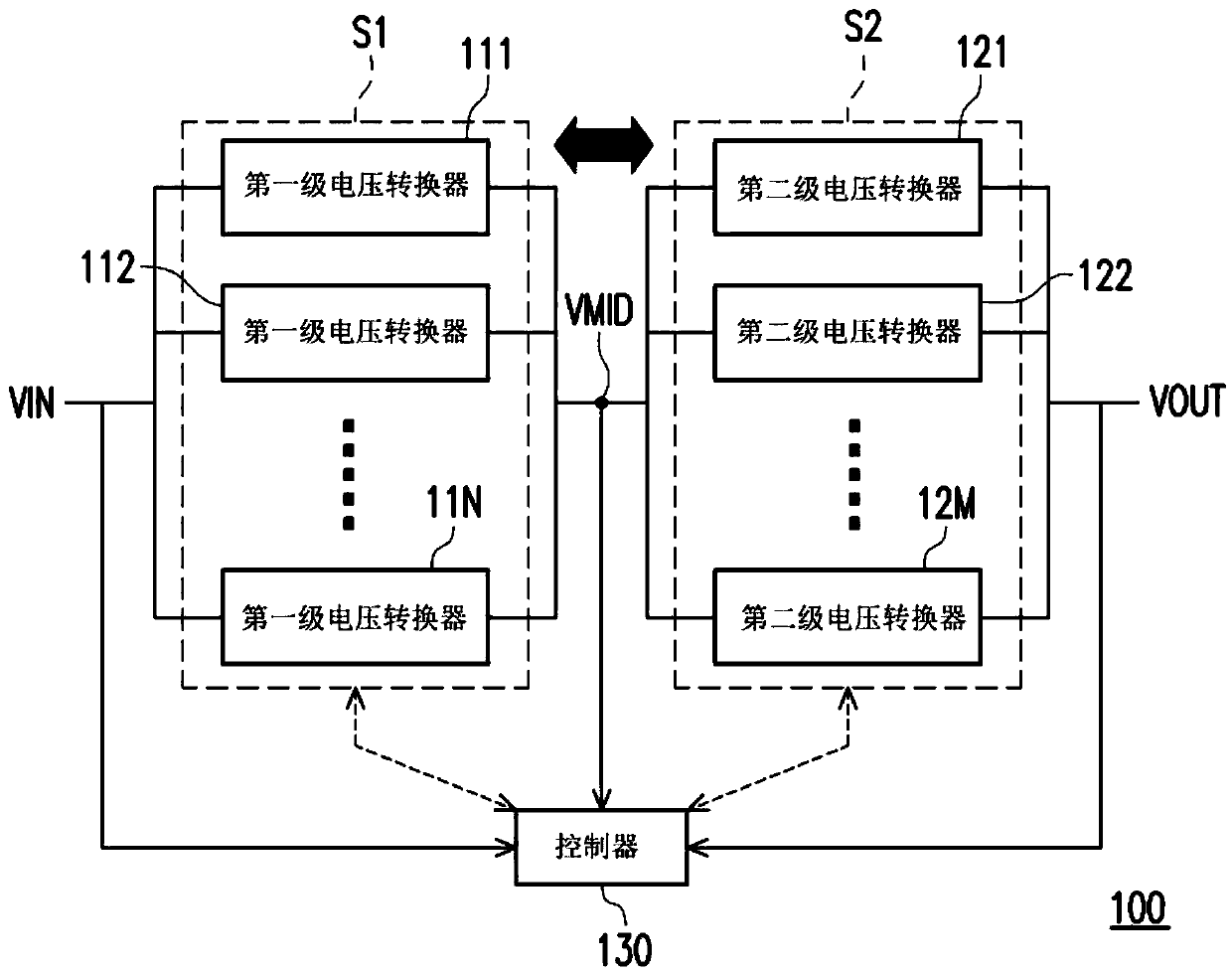

[0061] Please refer to figure 1 , figure 1A schematic diagram of a multi-phase power step-down system according to an embodiment of the present invention is shown. The multi-phase power step-down system 100 includes a plurality of first-stage voltage converters 111 - 11N, a plurality of second-stage voltage converters 121 - 12M and a controller 130 . The first-stage voltage converters 111 - 11N are coupled in parallel and form the voltage converters of the first level S1 . The first-stage voltage converters 111 - 11N jointly receive the input voltage VIN, and convert the input voltage VIN to generate the relay voltage VMID. A plurality of second-level voltage converters 121 - 12M are coupled in parallel to form a second level of voltage converters S2 . The second-stage voltage converters 121 - 12M jointly receive the relay voltage VMID, and convert the relay voltage VMID to generate the output voltage VOUT. The first-stage voltage converters 111-11N are used to respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com