Fresh corn harvester

A technology for fresh corn and harvesters, which is applied to harvesters, agricultural machinery and implements, etc. It can solve problems such as crop quality and yield reduction, mechanical damage to ears, time-consuming and labor-intensive problems, and reduce labor intensity. Social benefits and economic benefits, the effect of simple and convenient driving control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

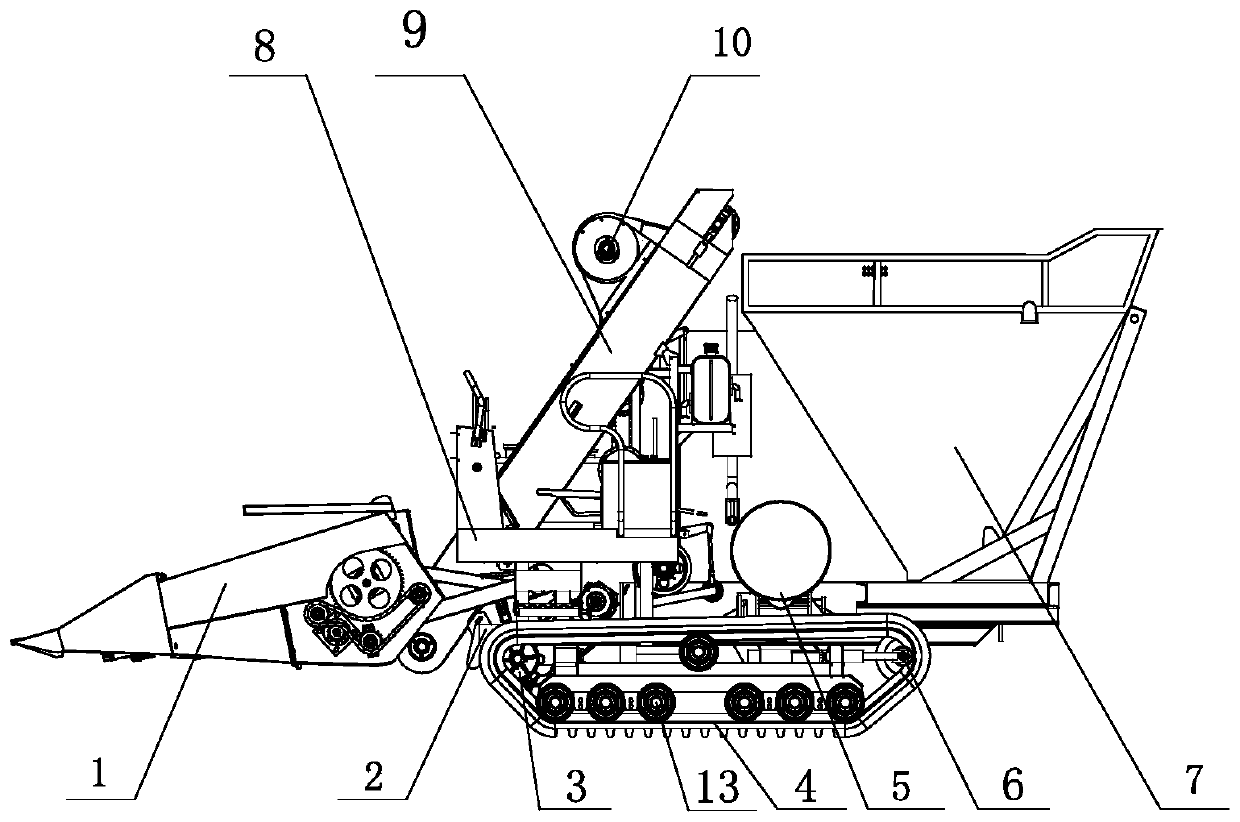

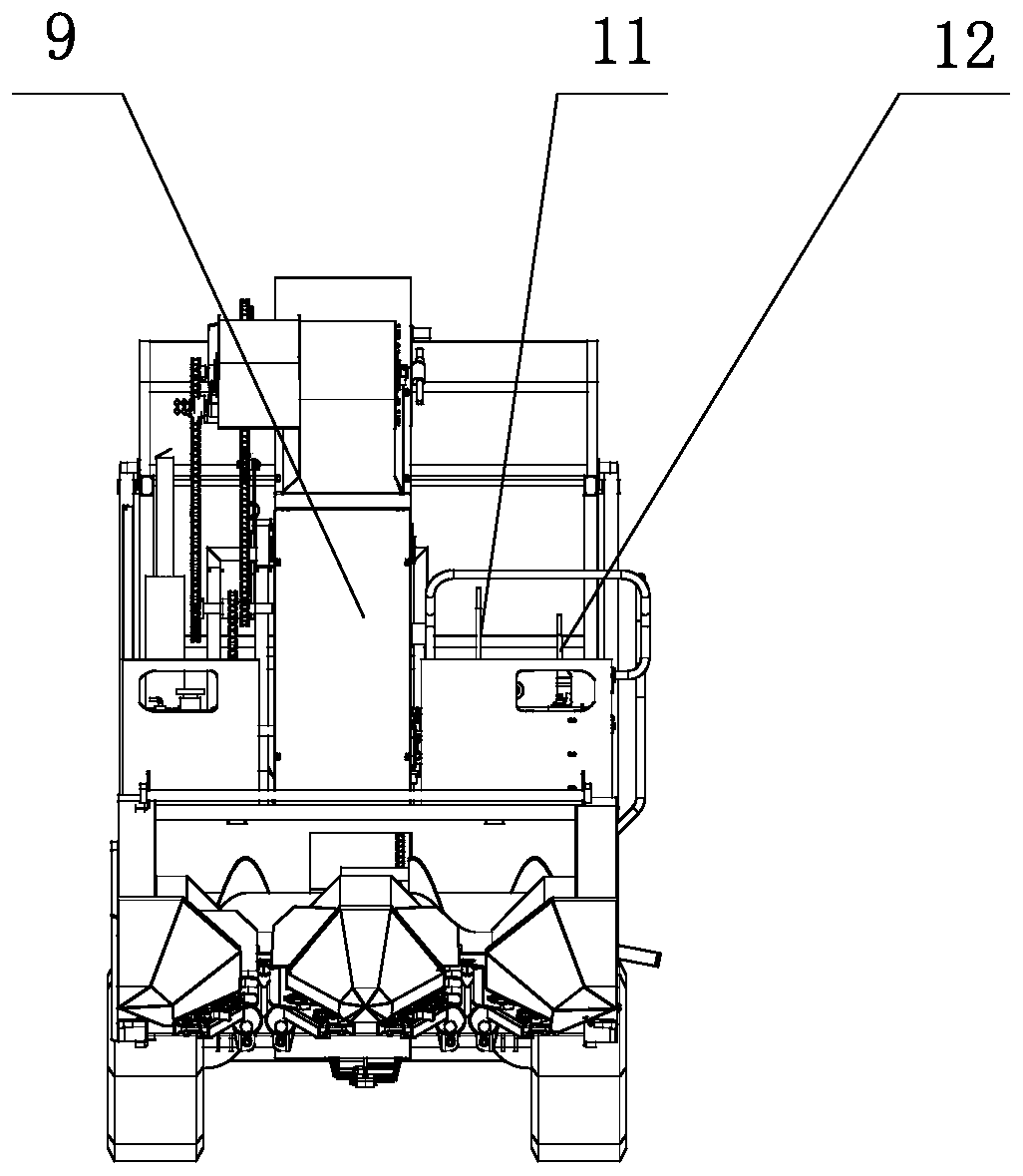

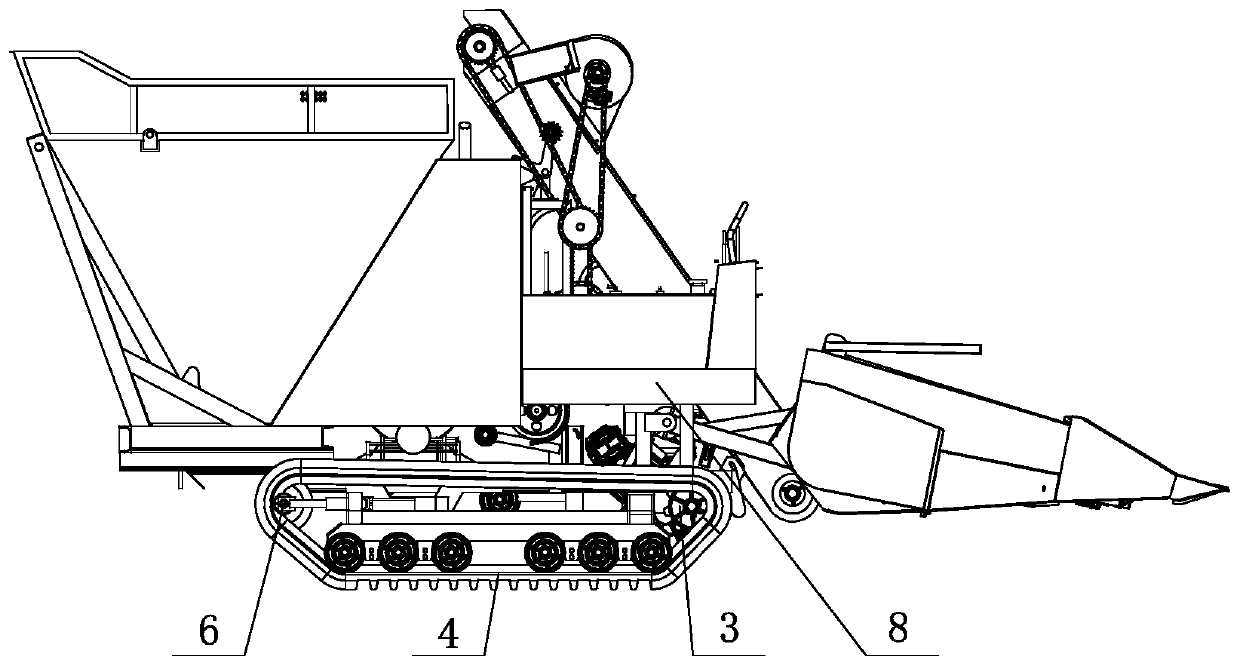

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] Such as Figure 1-4 As shown, the fresh corn harvester includes a harvesting work assembly and a walking chassis assembly, and the walking chassis assembly includes a crawler belt walking system, a gearbox, an HST device, a steering cylinder and a frame 2. The frame 2 is provided with a harvesting work assembly, and the harvesting work assembly is successively provided with a header device 1, a driving platform 8, an ear elevator 9, a power system 5 and an ear box 7 from front to back, and the ear elevator is transported Device 9 is arranged obliquely on driving platform 8 tops, and described fruit ear box 7 is arranged on the below of fruit ear elevator 9 top outlets.

[0025] The top of the described ear elevator 9 is equipped with a miscellaneous blower fan 10 .

[0026] Both sides of the frame 2 are equipped with a crawler walking system, and the crawler w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com