Bio-based insect trapping plate and preparation method thereof

An insect trap, bio-based technology, applied in the fields of trapping or killing insects, animal husbandry, application, etc., can solve the problem of rarely being effectively used, and achieve the goal of reducing the use of pesticides, protecting the environment, and promoting good promotion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] Example 1

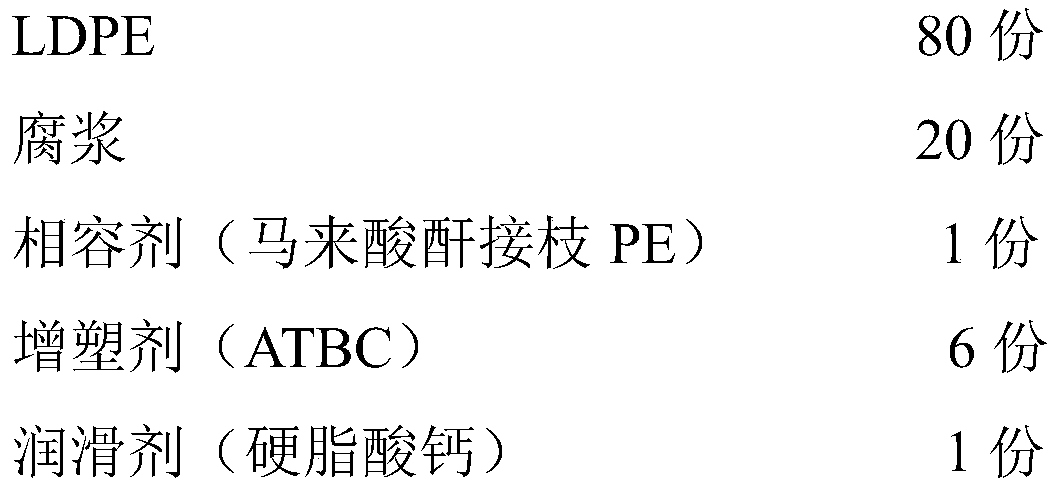

[0029] A bio-based insect trap and its preparation method, calculated by mass parts, its composition and content are as follows:

[0030]

[0031] The above formula reacts according to the following steps:

[0032] 1. Dry a certain amount of pulp first, and then crush it to 500-2000 mesh;

[0033] 2. Put the above slurry, compatibilizer maleic anhydride grafted PE, plasticizer ATBC, lubricant calcium stearate together with LDPE in a high-speed blender, and mix for 120min at a temperature of 90℃ and a rotation speed of 200rpm , Get the initial mixture;

[0034] 3. Place the above-mentioned preliminary mixture in a twin-screw extruder for extruding and granulation. The temperature from zone 1 to zone 6 is 180°C, 185°C, 190°C, 195°C, 195°C, 195°C, and the die temperature is 190°C. The screw speed is 300rpm, and the masterbatch is prepared;

[0035] 4. Put the above masterbatch into a sheet extruder, then extrude, shape, and cut to prepare a bio-based insect trap substra...

Example Embodiment

[0038] Example 2

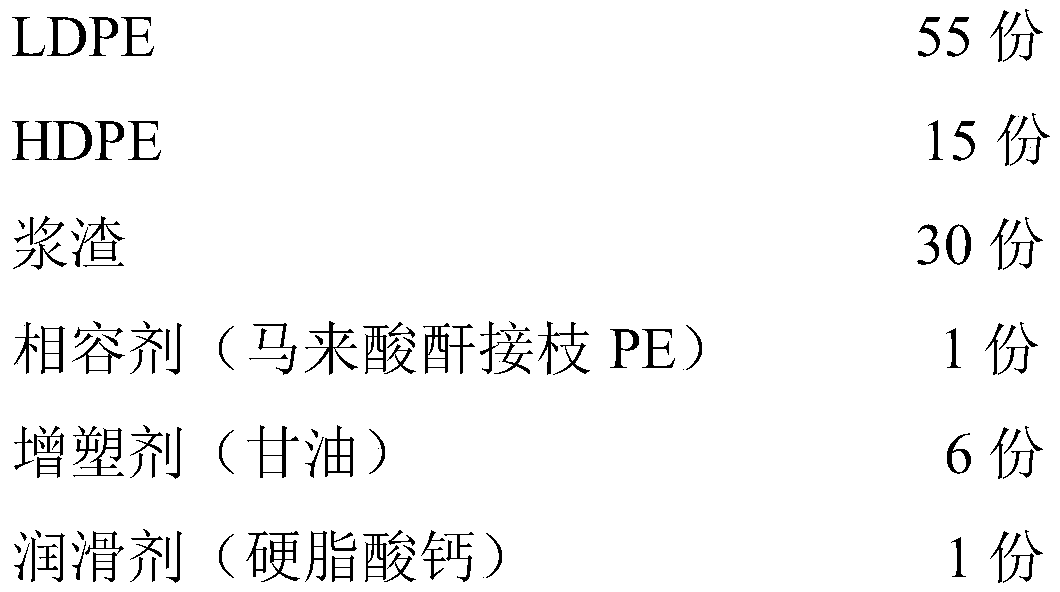

[0039] A bio-based insect trap and its preparation method, calculated by mass parts, its composition and content are as follows:

[0040]

[0041] The above formula reacts according to the following steps:

[0042] 1. Dry a certain amount of slurry first, and then crush it to 50-5000 mesh;

[0043] 2. Put the above slurry, compatibilizer maleic anhydride grafted PE, plasticizer glycerin, lubricant calcium stearate together with LDPE and HDPE in a high-speed blender at a temperature of 100°C and a rotation speed of 600rpm , Mix for 300min to obtain the initial mixture;

[0044] 3. Place the above-mentioned preliminary mixture in a twin-screw extruder for extruding and granulation. The temperature of zone 1 to zone 6 is 170℃, 175℃, 180℃, 185℃, 185℃, 185℃, and the die temperature is 150℃. The screw speed is 200rpm, and the masterbatch is prepared;

[0045] 4. Put the above masterbatch into a sheet extruder, then extrude, shape, and cut to prepare a bio-based insect trap...

Example Embodiment

[0048] Example 3

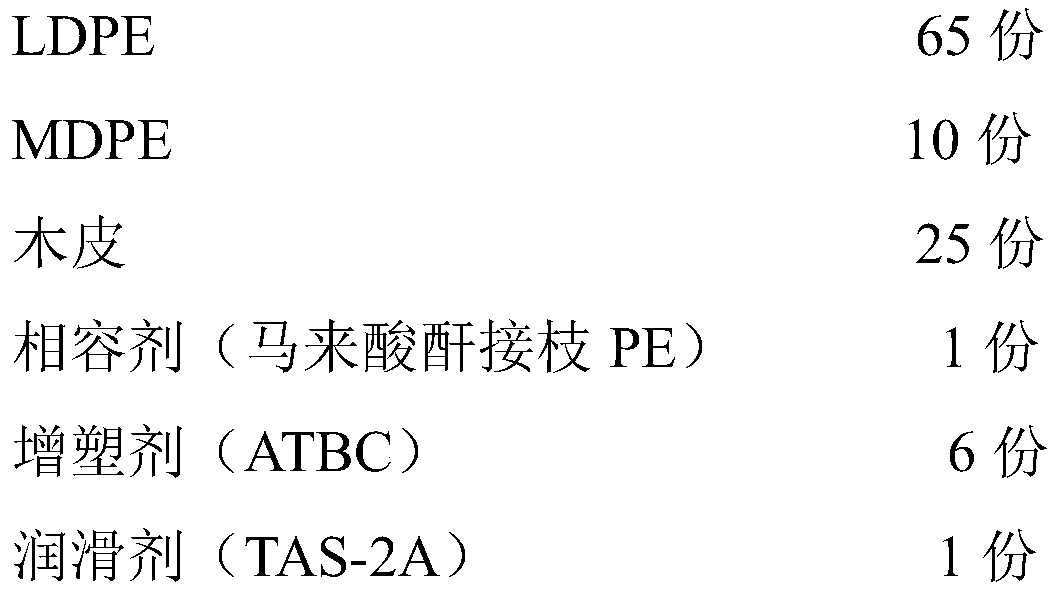

[0049] A bio-based insect trap and its preparation method, calculated by mass parts, its composition and content are as follows:

[0050]

[0051] The above formula reacts according to the following steps:

[0052] 1. Dry a certain amount of veneer first, and then crush it to 200-3000 mesh;

[0053] 2. Put the above veneer, compatibilizer maleic anhydride grafted PE, plasticizer ATBC, lubricant TAS-2A together with LDPE, MDPE in a high-speed blender, and mix at a temperature of 95°C and a rotation speed of 200 rpm. 30min, get the initial mixture;

[0054] 3. Place the above-mentioned preliminary mixture in a twin-screw extruder for extruding and granulation. The temperature from zone 1 to zone 6 is 160℃, 165℃, 170℃, 175℃, 175℃, 175℃, and the die temperature is 170℃. The screw speed is 150rpm, and the master batch is prepared

[0055] 4. Put the above masterbatch into a sheet extruder, then extrude, shape, and cut to prepare a bio-based insect trap substrate;

[0056] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com