Aerosol atomizer capable of preventing tar leakage during transportation and electronic cigarette comprising aerosol atomizer

An atomizer and aerosol technology, applied in the direction of tobacco, etc., can solve the problems of downward leakage, e-liquid outflow, and inability to hold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with examples, but the present invention is not limited in any way, and any transformation or substitution made based on the teaching of the present invention belongs to the protection scope of the present invention.

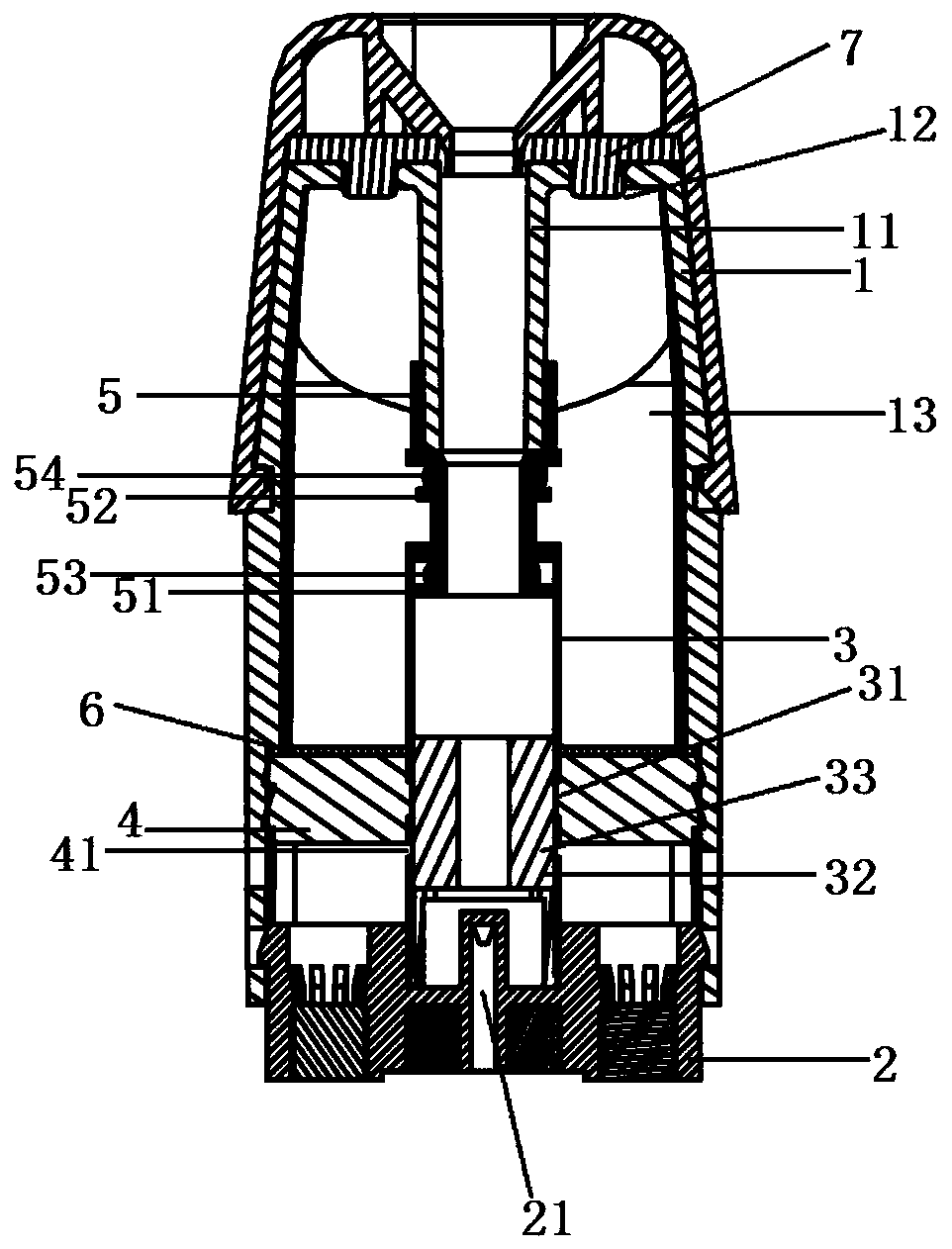

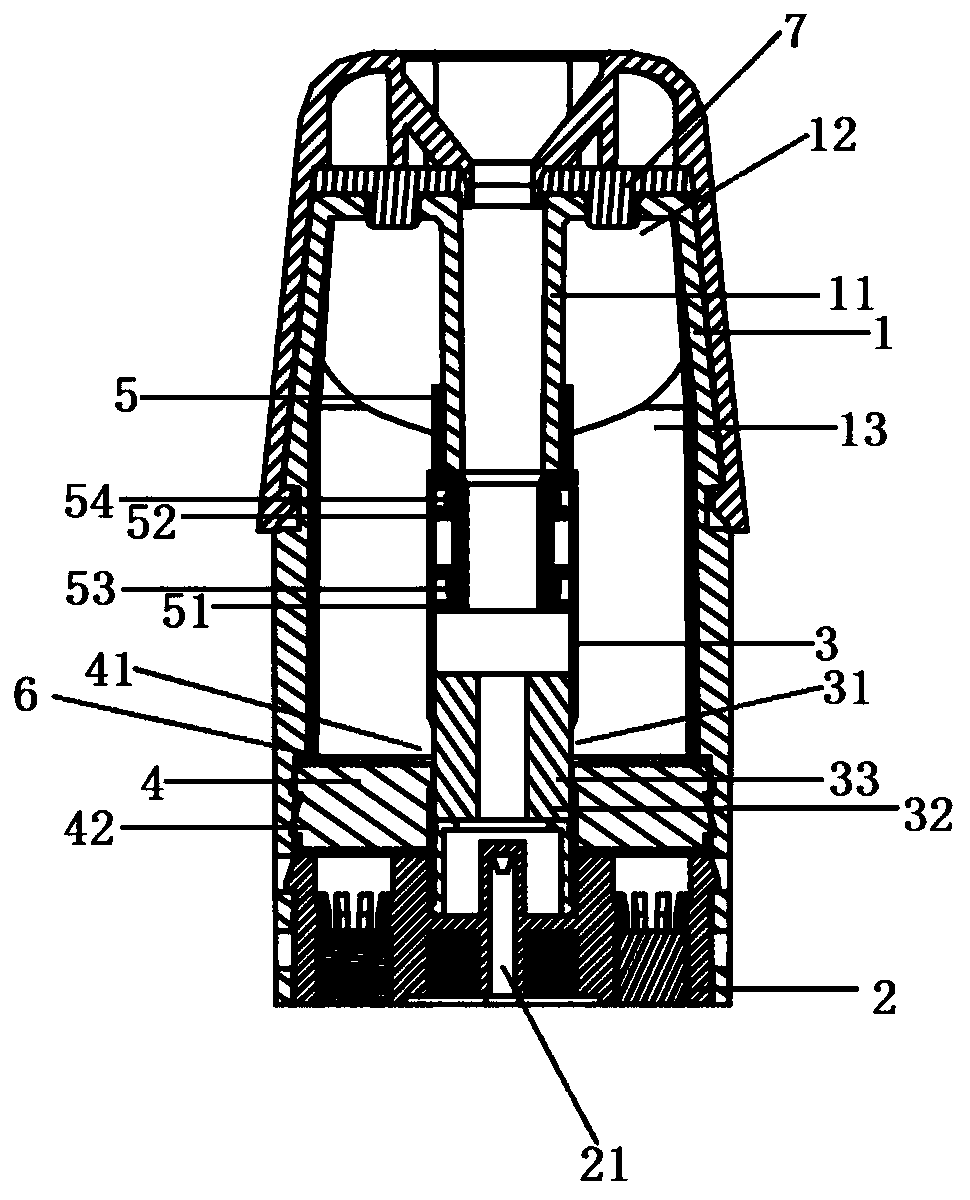

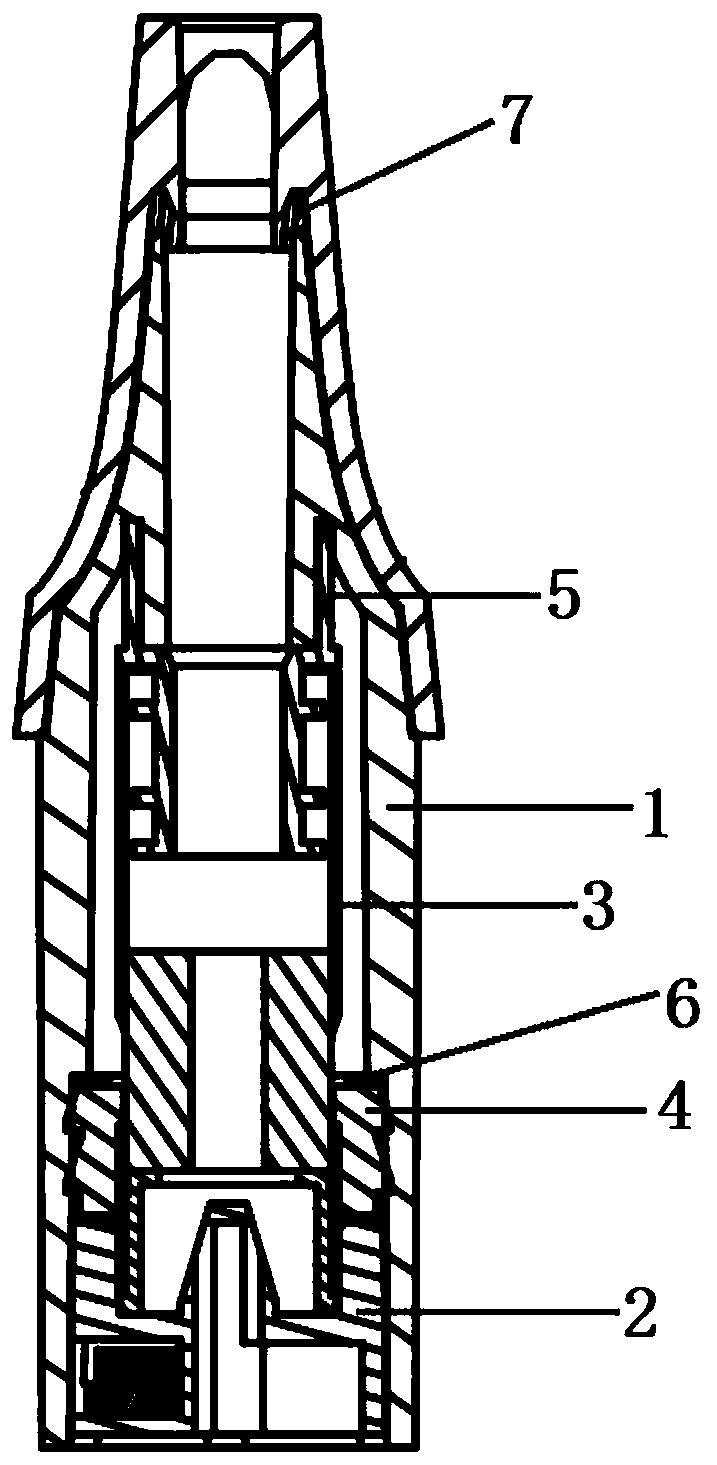

[0030] This embodiment provides an electronic cigarette that can avoid oil leakage during transportation, and the aerosol atomizer used in it includes:

[0031] Shell 1, the downstream of the shell 1 has an oil injection hole 12, which communicates with the oil storage bin 13 inside the shell 1; the downstream of the shell 1 has a flue gas channel 11;

[0032] The first pipe body 3 is located inside the housing 1 and has an atomizing core 32 and an oil guide cotton 33 inside;

[0033] A rubber plug 4, which has a central hole 41, the central hole 41 allows the passage of the first pipe body 3, and the rubber plug 4 is located in the clamping area of the housing 1;

[0034] Base 2, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com