Tool bar

A technology of tool holders and tool holders, which is applied in the direction of tool holders, etc., can solve the problems of affecting product accuracy, impossibility of precise machining, easy to carry tools, etc., and achieves the effect of easy operation, simple structure, and avoiding the replacement of tool holders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

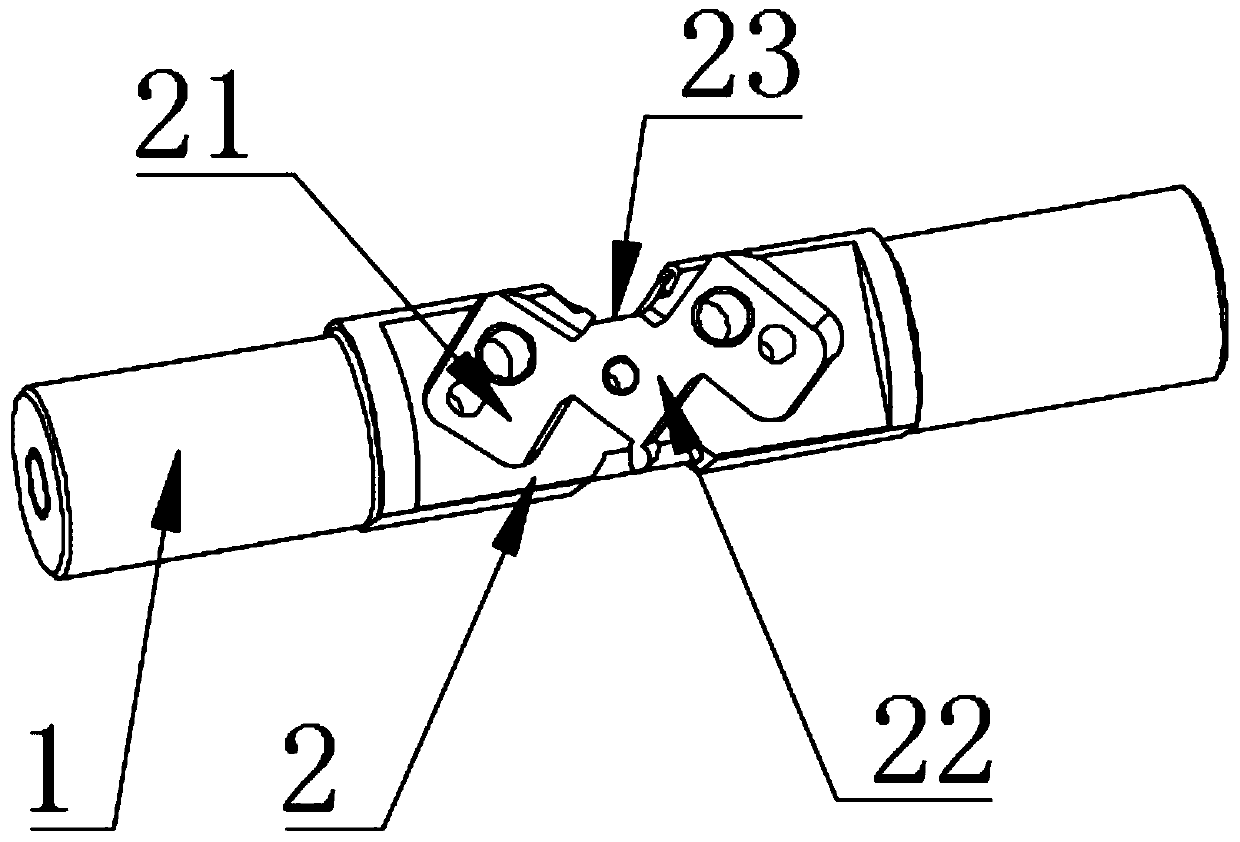

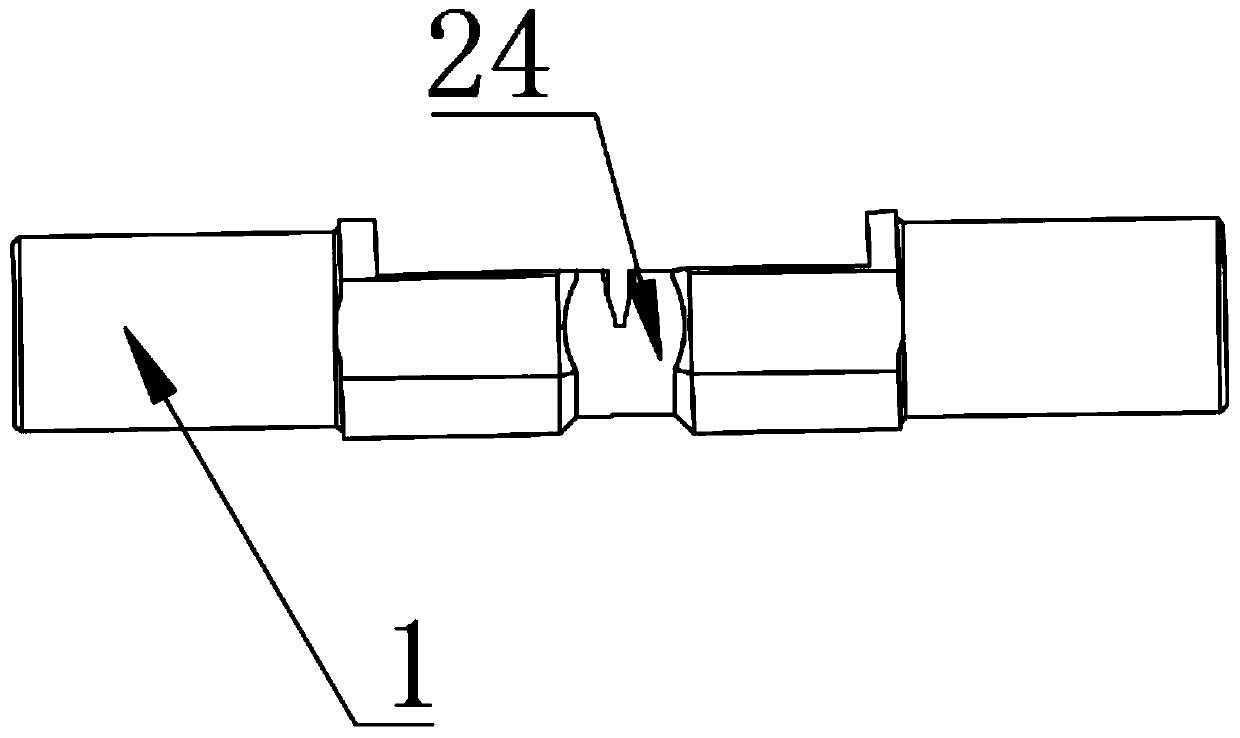

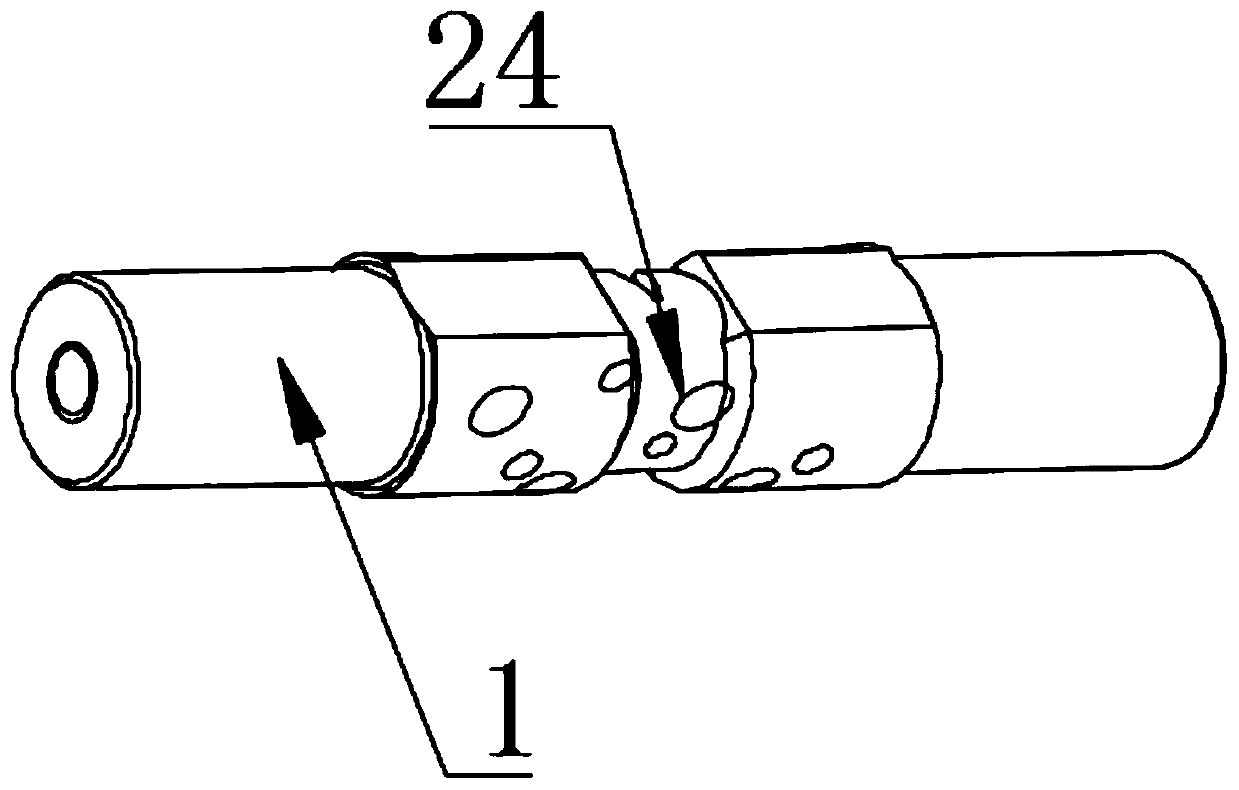

[0019] Such as Figure 1-Figure 3 As shown, a knife holder includes a knife holder 2, and the two axial ends of the knife holder 2 are provided with fixedly connected fixed shafts 1. The knife holder 2 is provided with a blade groove 22, and the blade groove 22 is provided with Connected fastening platen groove 21, blade groove 22 radial side is provided with knife edge 23, is provided with carrying knife groove 24 on the knife rest 2, carries knife groove 24 and is positioned at blade groove 22 below.

[0020] Such as image 3 As shown, the knife carrying groove 24 is an annular groove along the radial direction of the blade groove 22 .

[0021] Such as Figure 4-Figure 5 As shown, the fastening platen groove 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com