A finishing process method for the inner cavity of the buoy of the liquid floating gyroscope

A liquid floating gyroscope and process method technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of unstable quality and low production efficiency, reduce production costs, improve processing efficiency, and auxiliary time. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings; the present embodiments are descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

[0034] A process method for finishing the inner cavity of a floating gyroscope buoy, the steps are as follows:

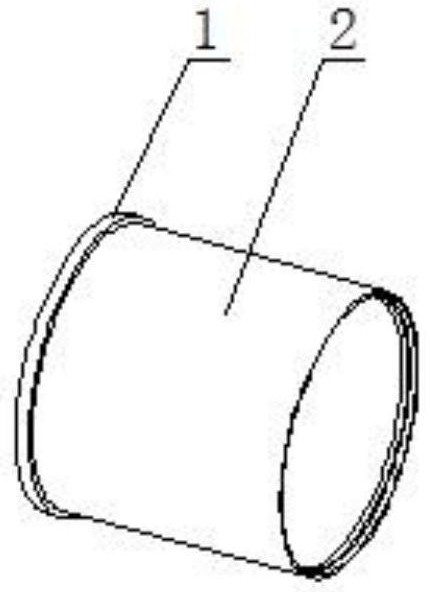

[0035] ⑴ Process handle processing of buoy

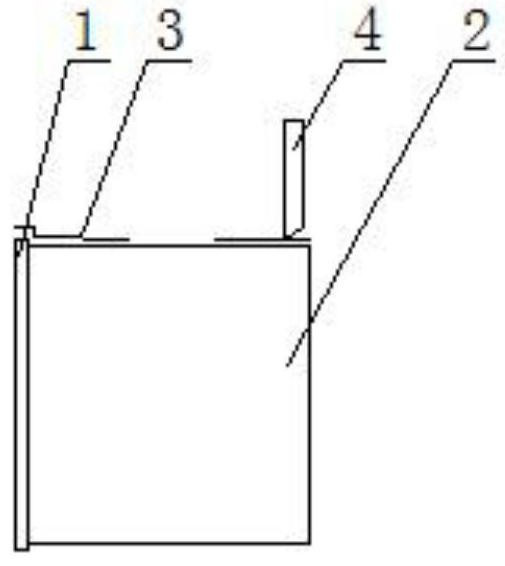

[0036] Carry out rough turning on the outer wall of the buoy workpiece 2, and leave a boss 1 at the end of the buoy as a process handle, that is, when rough turning the outer wall of the buoy, reserve a space for compaction for the finishing process of the inner cavity of the buoy Craft handles such as figure 1 shown. The tool path during rough turning is as follows: figure 2 As shown, the buoy workpiece is fixed on the lathe as usual, and the turning tool 4 is used to process the process shank according to the tool path 3, and a boss is reserved during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com