A dust-removing aluminum veneer polishing equipment

An aluminum veneer and equipment technology, applied in the field of aluminum veneer polishing equipment, can solve problems such as reducing the surface roughness of workpieces, polluting the environment, and affecting the health of operators, so as to improve work efficiency, simplify the polishing process, and achieve efficiency and flexibility. sex enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

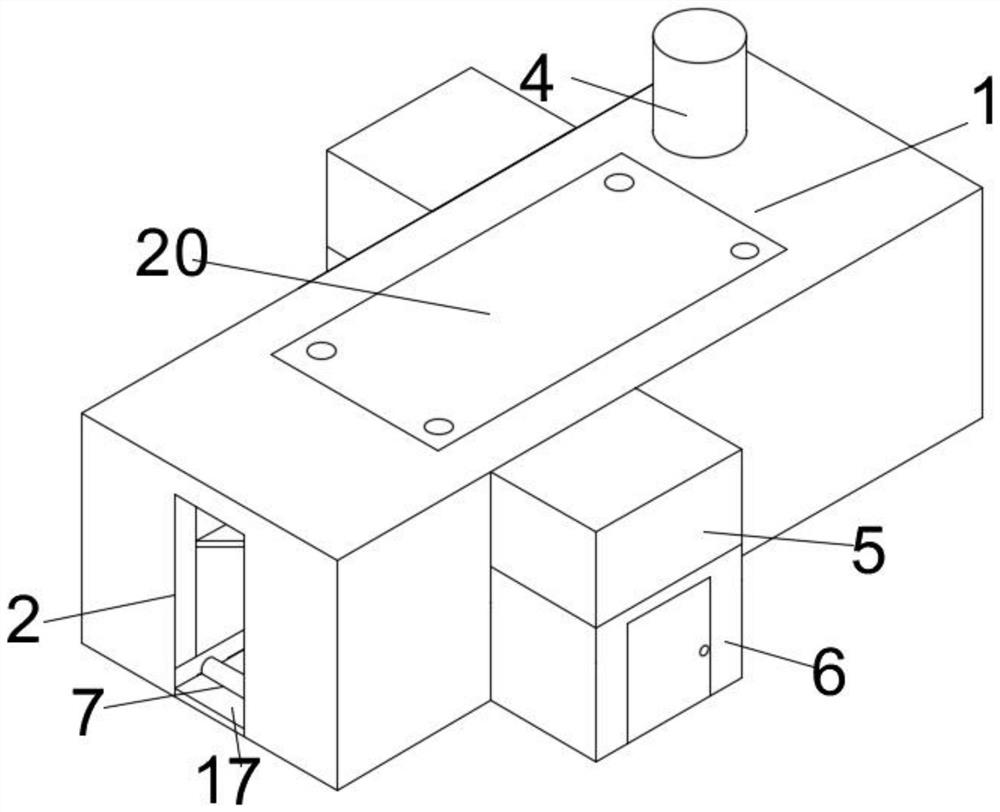

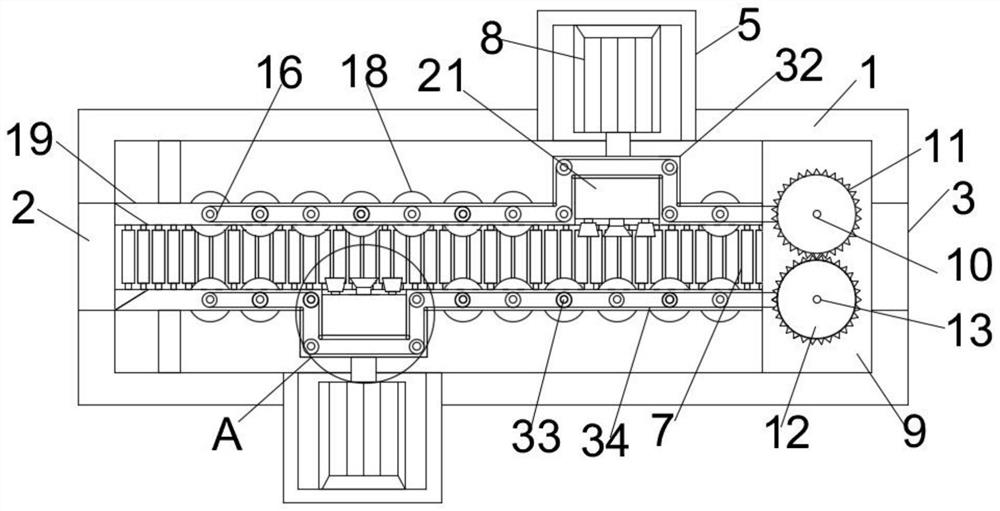

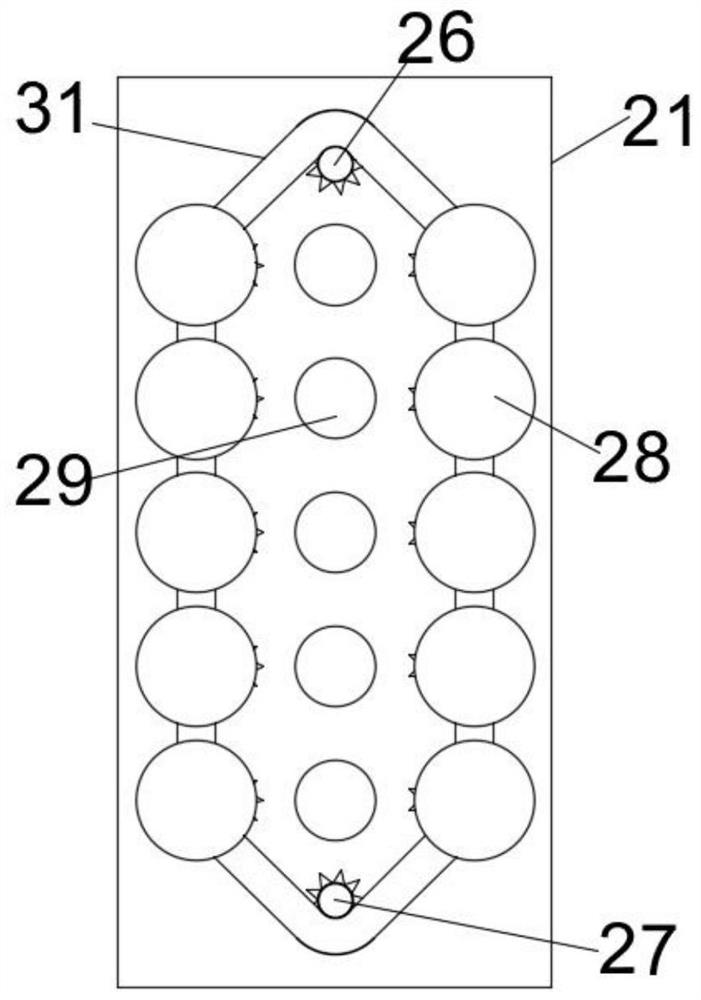

[0032] Embodiment: Turn on the first motor 4 and the second motor 8, put the aluminum veneer to be polished into the cabinet 1 vertically from the entrance 2 of the cabinet 1, and when it is inside the cabinet 1, it will be subjected to two The clamping of the cylinder 18 on the side horizontal plate 19 moves to the outlet 3 under the drive of the first motor 4, and when it moves to the polishing plate 21, the second motor 8 electric chain 31 rotates, so that the polishing sheet 28 moves in an arc, Polish the entire surface of the aluminum veneer, and then turn on the vacuum cleaner 23, so that the polished dust can be inhaled by the vacuum nozzle 29 in time, and enter the vacuum cleaner 23 through the vacuum hose 24 for collection until the aluminum veneer is collected by the roller 18 Clamp and move to exit 3, and then collect and store manually.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com