A kind of material water separation device and method

A technology for separating devices and materials, which is applied to the removal of solid waste, presses, garbage collection, etc. It can solve the problems of mixed dry and wet garbage, easy to mold and smell, and achieve the effect of avoiding mold and smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

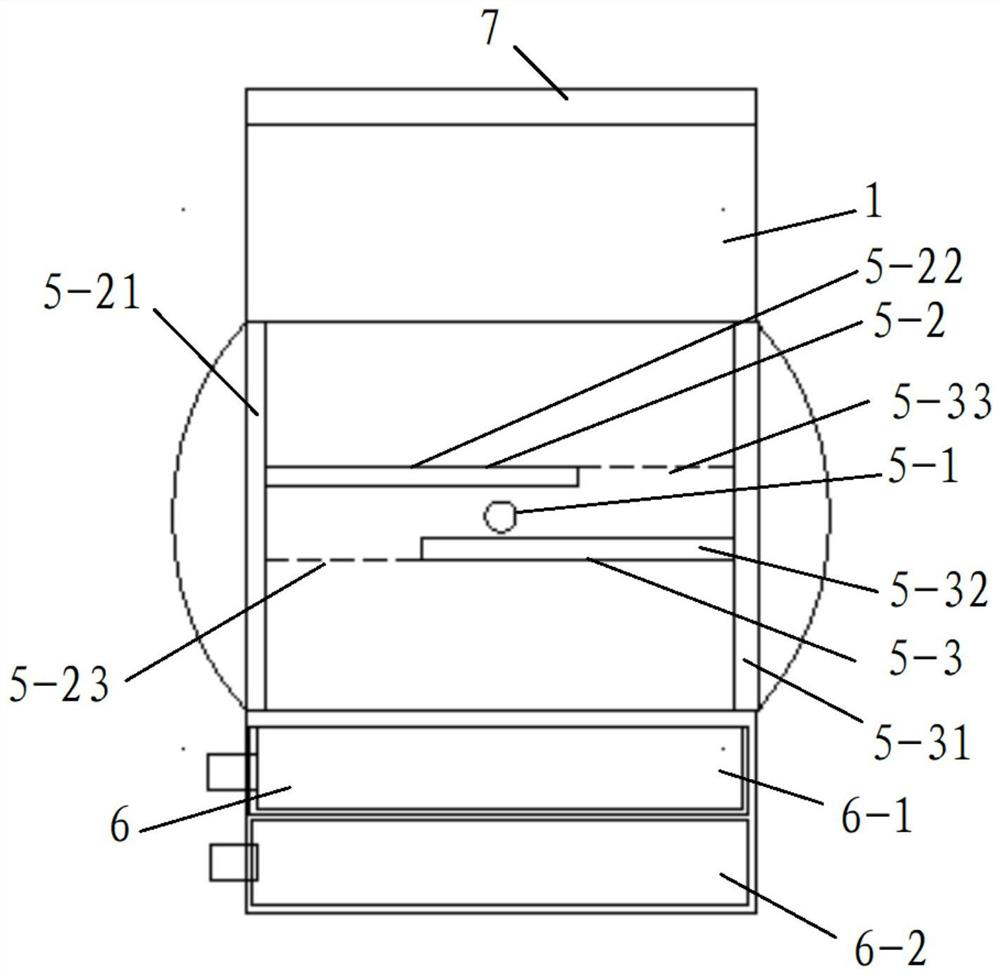

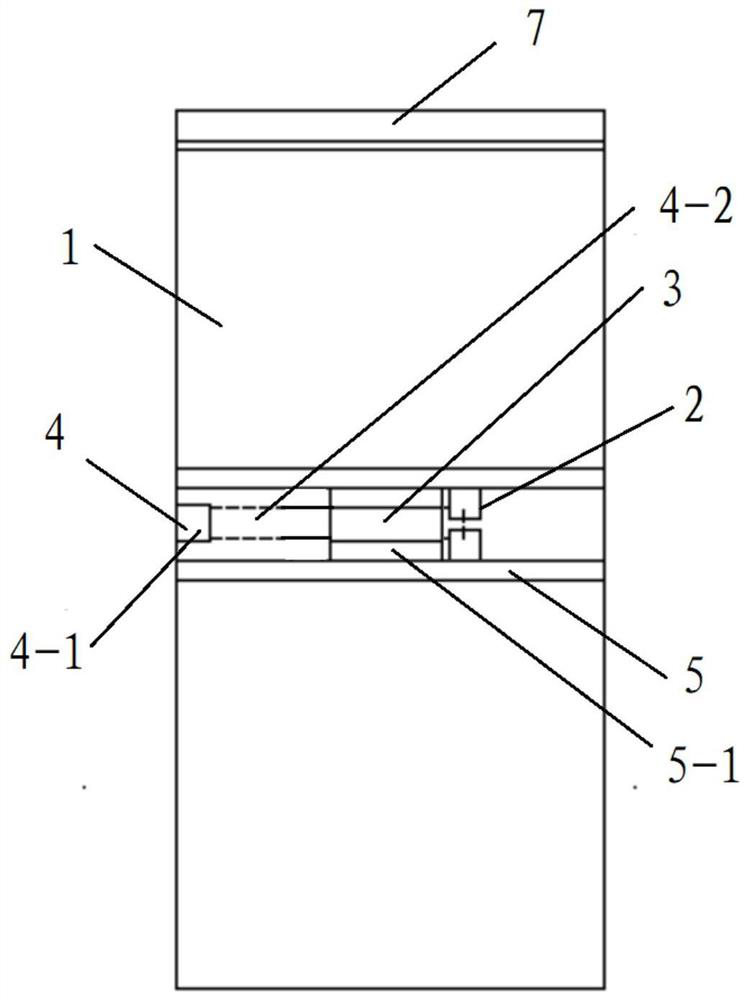

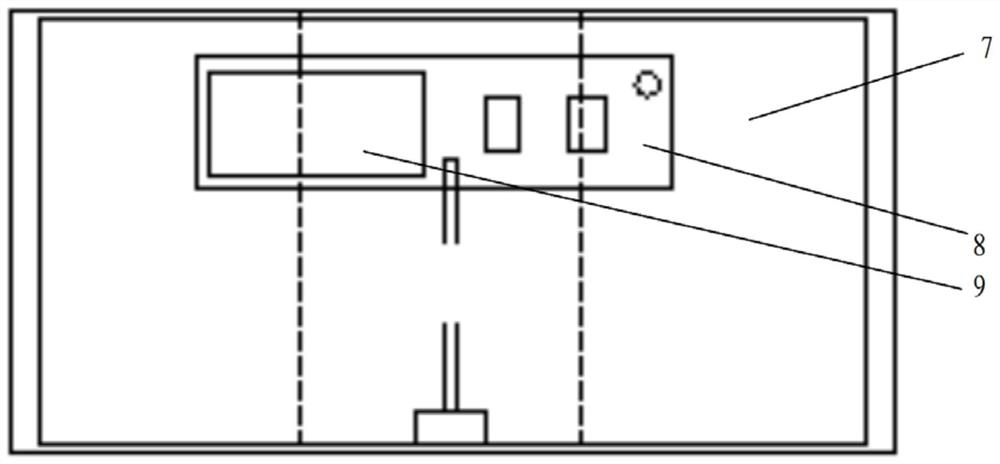

[0023] see Figure 1-3 , A material moisture separation device provided in an embodiment of the present invention includes: a barrel body 1 , a deck 2 , a stick 3 , a driving mechanism 4 and an extruding mechanism 5 .

[0024] Both the driving mechanism 4 and the extruding mechanism 5 are arranged in the barrel body 1 .

[0025] The driving mechanism 4 includes: a rotating motor 4-1 and a telescopic shaft 4-2.

[0026] The fixed end of the rotary motor 4-1 is fixedly arranged in the barrel body 1, and the action end of the rotary motor 4-1 is fixedly connected with the first end of the telescopic shaft 4-2.

[0027] The second end of the telescopic shaft 4-2 is fixedly connected with the stick 3.

[0028] The extrusion mechanism 5 includes: a gear 5-1, a first extrusion part 5-2 and a second extrusion part 5-3.

[0029] The gear 5-1 is arranged between the first extrusion part 5-2 and the second extrusion part 5-3, and the gear 5-1 meshes with the first extrusion part 5-2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com