Antibacterial mildew-resistant water-curable polyurethane building waterproof paint, and preparation method thereof

An antibacterial, mildew-proof and building waterproof technology, which is applied in the preparation of antibacterial and mildew-proof water-curable polyurethane architectural waterproof coatings, and in the field of antibacterial and mildew-proof water-curable polyurethane architectural waterproof coatings, which can solve the problem of uneven quality of waterproof coatings and short service life of coatings , mildew and deterioration of the coating, etc., to achieve the effect of improving loss resistance and long-term performance, excellent antibacterial and mildew resistance, and improving surface hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

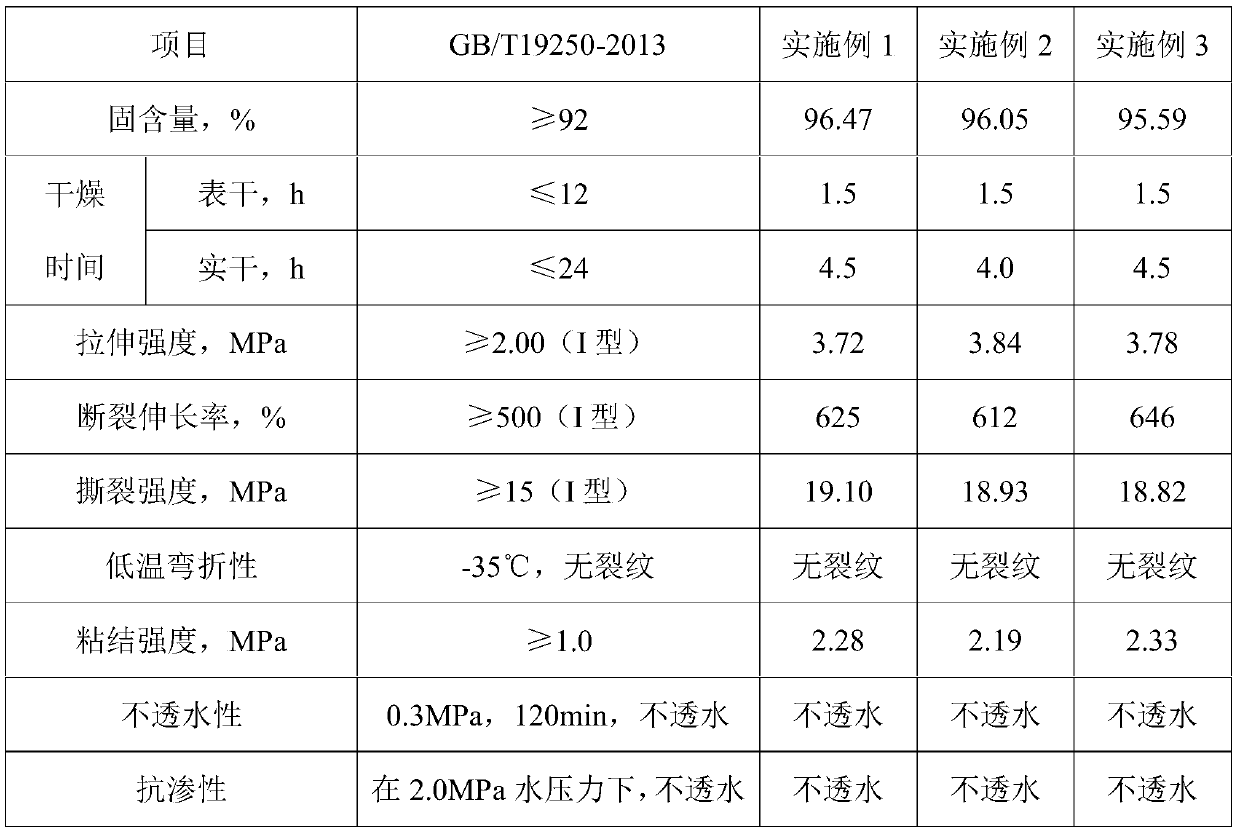

Examples

Embodiment 1

[0042] The preparation method of the antibacterial and mildew-proof type water-based polyurethane emulsion of the architectural waterproof coating of the present embodiment may further comprise the steps:

[0043] 1) tetradecyl dimethyl benzyl ammonium chloride and bis-octyl dimethyl ammonium chloride are dissolved in water to make a total mass concentration of 10.0% quaternary ammonium salt solution, wherein, tetradecyl di The molar ratio of methyl benzyl ammonium chloride to dialkyl dimethyl ammonium chloride is 1.5:1; take sodium-based montmorillonite and disperse it in water to make a suspension with a mass concentration of 10.0%, and set aside;

[0044] According to the molar ratio of the cation exchange capacity of the quaternary ammonium salt and the sodium montmorillonite being 2.0:1, the quaternary ammonium salt solution was mixed with the suspension at 80° C., stirred and reacted for 6.0 h, filtered to obtain a solid product, and Wash with ethanol water to free of Cl...

Embodiment 2

[0050] The preparation method of the antibacterial and mildew-proof type water-based polyurethane emulsion of the architectural waterproof coating of the present embodiment may further comprise the steps:

[0051] 1) tetradecyl dimethyl benzyl ammonium chloride and bis-octyl dimethyl ammonium chloride are dissolved in water to make a total mass concentration of 10.0% quaternary ammonium salt solution, wherein, tetradecyl di The molar ratio of methyl benzyl ammonium chloride to dialkyl dimethyl ammonium chloride is 1.7:1; take sodium montmorillonite and disperse it in water to make a suspension with a mass concentration of 10.0%, and set aside;

[0052] According to the molar ratio of the cation exchange capacity of the quaternary ammonium salt and the sodium montmorillonite being 1.8:1, the quaternary ammonium salt solution was mixed with the suspension at 85°C, stirred and reacted for 4.0h, and the solid product was obtained by filtration and used Wash with ethanol water to f...

Embodiment 3

[0058] The preparation method of the antibacterial and mildew-proof type water-based polyurethane emulsion of the architectural waterproof coating of the present embodiment may further comprise the steps:

[0059] 1) tetradecyl dimethyl benzyl ammonium chloride and bis-octyl dimethyl ammonium chloride are dissolved in water to make a total mass concentration of 10.0% quaternary ammonium salt solution, wherein, tetradecyl di The molar ratio of methyl benzyl ammonium chloride to dialkyl dimethyl ammonium chloride is 2.0:1; take sodium montmorillonite and disperse it in water to make a suspension with a mass concentration of 10.0%, and set aside;

[0060] According to the molar ratio of the cation exchange capacity of the quaternary ammonium salt and the sodium montmorillonite being 1.8:1, the quaternary ammonium salt solution was mixed with the suspension at 80° C., stirred and reacted for 5.0 h, filtered to obtain a solid product, and Wash with ethanol water to free of Cl - , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com