Preparation process of modified insole

A preparation process and a technology for insole, which are applied in the field of preparation technology of modified insole, can solve the problems of not thoroughly considering the insole's wear resistance, anti-skid and antibacterial effect, bacterial or fungal infection of human feet, poor antibacterial effect of the insole, etc., and achieve the structure of the insole. The design and process design are novel, improve the use value, and avoid the effect of bacterial growth and mildew and odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

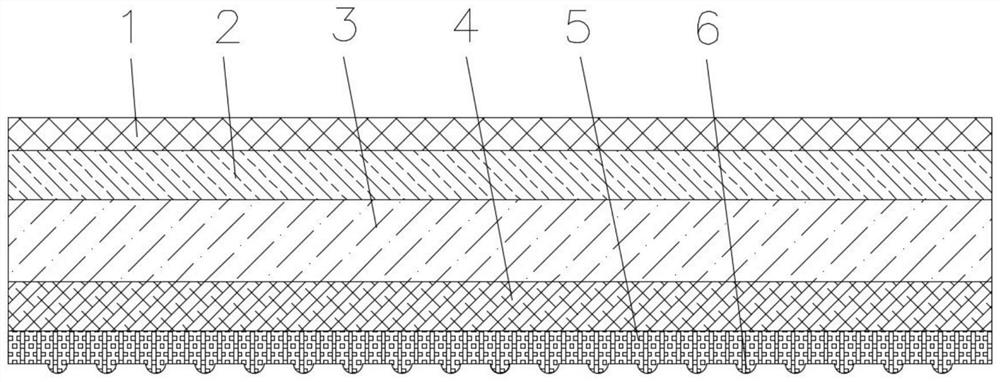

[0042] Example 1, such as figure 1 Shown:

[0043] A preparation process for a modified insole, comprising the steps of:

[0044] Step 1: Foaming material preparation: prepare 30 parts of polyethylene, 15 parts of talcum powder, 0.8 parts of crosslinking agent, 10 parts of crosslinking auxiliary agent, 5 parts of foaming agent, 3 powders of foaming auxiliary agent, lubrication 1 part of agent, 0.5 part of silicon carbide powder, 3 parts of bamboo charcoal fiber and 0.5 part of corundum powder;

[0045] Step 2: Preparation of mixed powder: prepare 10 parts of prickly ash powder, 5 parts of mugwort leaf powder, 3 parts of cinnamon dry powder, 1 part of flavescens dry powder, 1 part of safflower dry powder, 10 parts of cassia twig dry powder and 10 parts of notopterygium dry powder according to the mass parts;

[0046] Step 3: Put the foaming materials prepared in Step 1 into a mixer with a temperature of 130° C. for kneading treatment to obtain a foaming mixture;

[0047] Ste...

Embodiment 2

[0059] Example 2, such as figure 1 Shown:

[0060] A preparation process for a modified insole, comprising the steps of:

[0061] Step 1: Foaming material preparation: Prepare 60 parts of polyethylene, 20 parts of talcum powder, 1.2 parts of crosslinking agent, 12 parts of crosslinking auxiliary agent, 8 parts of foaming agent, 5 parts of foaming auxiliary agent, lubrication 2 parts of agent, 1.5 parts of silicon carbide powder, 5 parts of bamboo charcoal fiber and 2.5 parts of corundum powder;

[0062] Step 2: Preparation of mixed powder: prepare 20 parts of prickly ash powder, 10 parts of mugwort leaf powder, 5 parts of cinnamon dry powder, 2 parts of flavescens dry powder, 2 parts of safflower dry powder, 15 parts of cassia twig dry powder and 20 parts of notopterygium dry powder according to the mass parts;

[0063] Step 3: Put the foaming materials prepared in Step 1 into a mixer at a temperature of 140° C. for mixing to obtain a foaming mixture;

[0064] Step 4: Steri...

Embodiment 3

[0074] Example 3, such as figure 1 Shown:

[0075] A preparation process for a modified insole, comprising the steps of:

[0076] Step 1: Foaming material preparation: prepare 45 parts of polyethylene, 18 parts of talcum powder, 1 part of crosslinking agent, 11 parts of crosslinking auxiliary agent, 6 parts of foaming agent, 4 parts of foaming auxiliary agent, lubrication 1.5 parts of agent, 1 part of silicon carbide powder, 4 parts of bamboo charcoal fiber and 2 parts of corundum powder;

[0077] Step 2: Preparation of mixed powder: prepare 15 parts of prickly ash powder, 8 parts of mugwort leaf powder, 4 parts of cinnamon dry powder, 1.5 parts of flavescens dry powder, 1.5 parts of safflower dry powder, 12 parts of cassia twig dry powder and 15 parts of notopterygium dry powder according to the mass parts;

[0078] Step 3: Put the foaming materials prepared in Step 1 into a mixer at a temperature of 135° C. for kneading treatment to obtain a foaming mixture;

[0079] Step 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com