Inorganic phase-change constant-temperature material and preparation method thereof

An inorganic phase change and constant temperature technology, which is applied in the direction of heat exchange materials, chemical instruments and methods, can solve problems such as degradation of thermophysical properties, and achieve the effects of good plasticity, stable performance, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

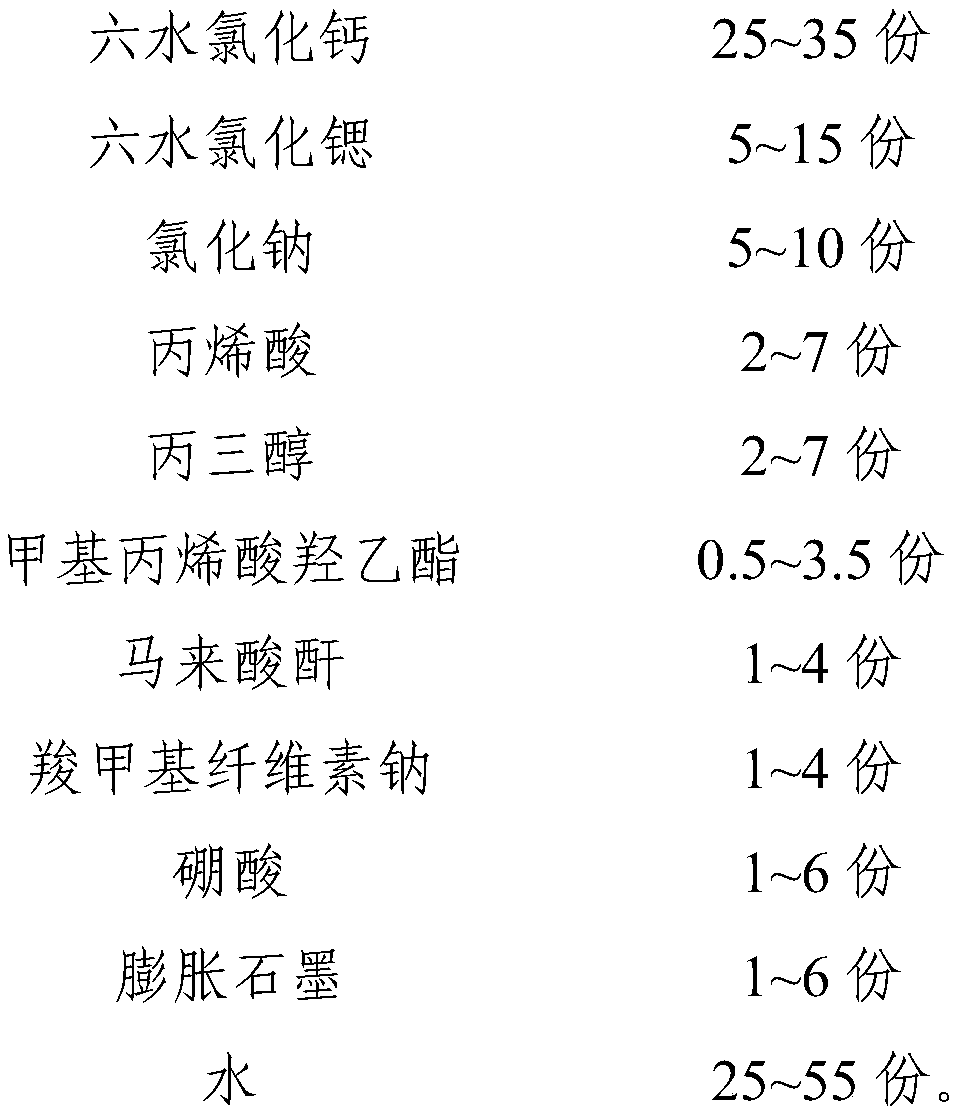

[0035] This embodiment provides an inorganic phase change constant temperature material, including the following components by weight:

[0036]

[0037] The preparation method of the inorganic phase change constant temperature material is as follows:

[0038] (1) After mixing acrylic acid and 15% water at 30-40°C, add strontium chloride hexahydrate to obtain mixed solution I;

[0039] (2) adding sodium chloride to the mixed solution I, then adding 5% water, and reacting at 45° C. for 1 hour to obtain the mixed solution II;

[0040] (3) After mixing glycerol with 6% water, add hydroxyethyl methacrylate and sodium hydroxycellulose to obtain mixed solution III;

[0041] (4) adding calcium chloride hexahydrate after mixing boric acid, expanded graphite, the mixed solution II and the mixed solution III, and reacting at normal pressure and 40° C. for 1 hour to obtain a polymer material;

[0042] (5) After mixing the polymer material and maleic anhydride, add the remaining part ...

Embodiment 2

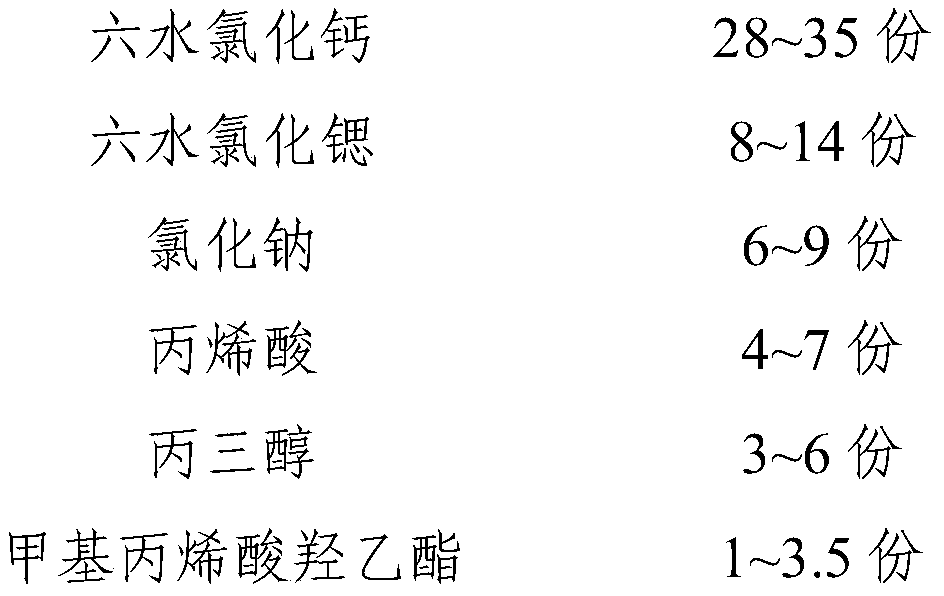

[0045] This embodiment provides an inorganic phase change constant temperature material, including the following components by weight:

[0046]

[0047] The preparation method of the inorganic phase change constant temperature material is as follows:

[0048] (1) After mixing acrylic acid and 14% water at 30-40°C, add strontium chloride hexahydrate to obtain mixed solution I;

[0049] (2) adding sodium chloride to the mixed solution I, then adding 6% water, and reacting at 45° C. for 1 hour to obtain the mixed solution II;

[0050] (3) After mixing glycerol with 6% water, add hydroxyethyl methacrylate and sodium hydroxycellulose to obtain mixed solution III;

[0051] (4) After mixing boric acid, expanded graphite, the mixed solution II and the mixed solution III, calcium chloride hexahydrate is added, and the reaction is carried out at normal pressure and 45° C. for 1 hour to obtain a polymer material;

[0052] (5) After mixing the polymer material and maleic anhydride, a...

Embodiment 3

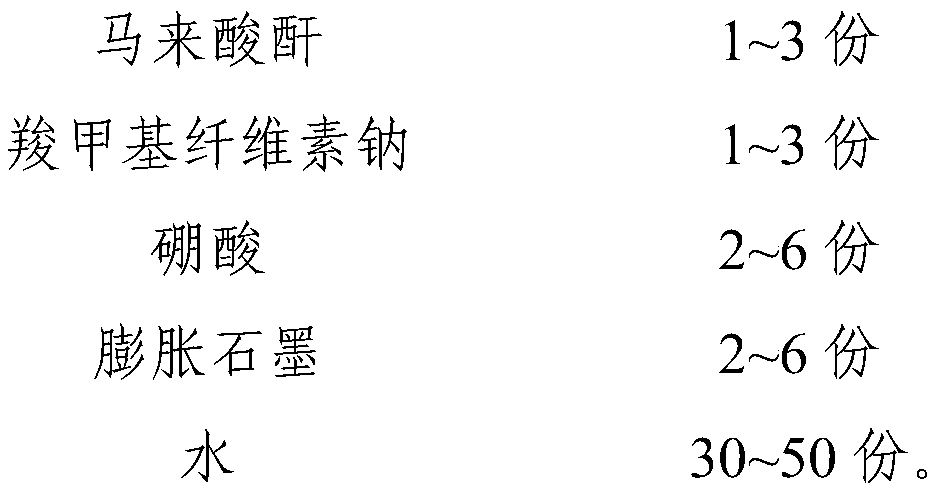

[0055] This embodiment provides an inorganic phase change constant temperature material, including the following components by weight:

[0056]

[0057] The preparation method of the inorganic phase change constant temperature material is as follows:

[0058] (1) After mixing acrylic acid and 13% water at 30-40°C, add strontium chloride hexahydrate to obtain mixed solution I;

[0059] (2) adding sodium chloride to the mixed solution I, then adding 3% water, and reacting at 45°C for 1 hour to obtain the mixed solution II;

[0060] (3) After mixing glycerol with 5% water, add hydroxyethyl methacrylate and sodium hydroxycellulose to obtain mixed solution III;

[0061] (4) After mixing boric acid, expanded graphite, the mixed solution II and the mixed solution III, calcium chloride hexahydrate is added, and the reaction is carried out at normal pressure and 45° C. for 0.8 h to obtain a polymer material;

[0062] (5) After mixing the polymer material and maleic anhydride, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com