Lubricant composition for RV speed reducer of robot

A technology of lubricant composition and reducer, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of poor wear resistance, difficulty in manufacturing grease compositions that meet long-term wear resistance and loadability, etc. Initial wear and long-term wear resistance, satisfying the effect of high-precision long-cycle operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

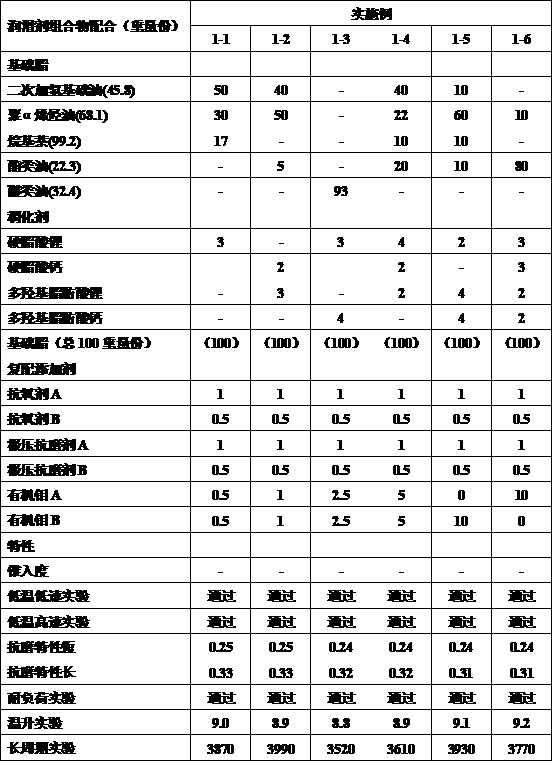

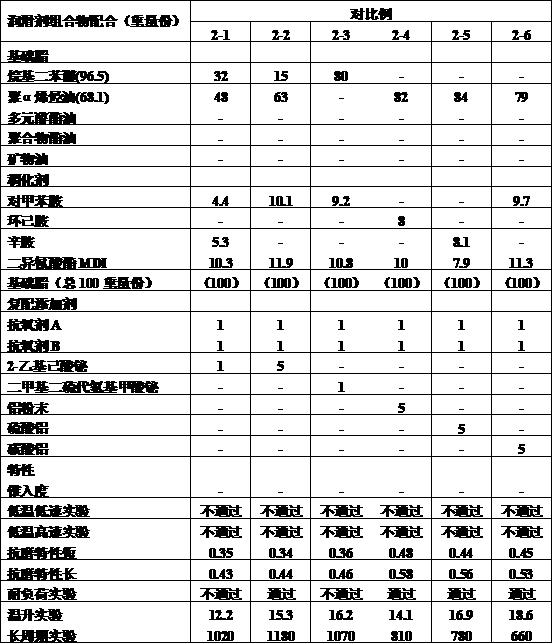

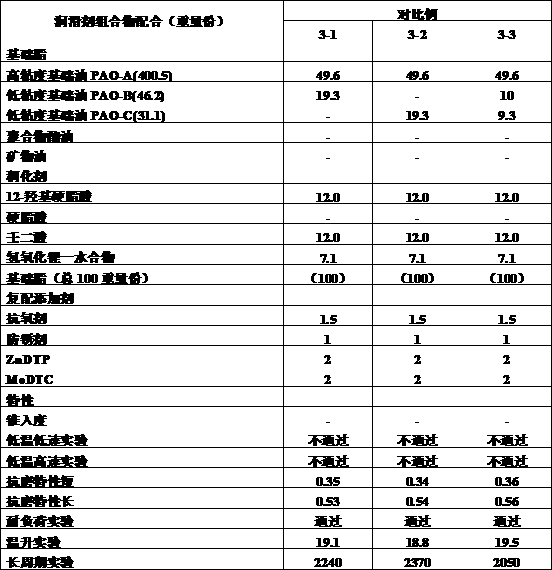

[0023] Example 1-1~Example 1-6, Comparative Example 2-1~Comparative Example 2-6 and Comparative Example 3-1~Comparative Example 3-3, in Table 1~Table 3, the base oil viscosity is 40°C kinematic viscosity at mm 2 / S.

[0024] In the base oils shown in Table 1, dissolve the thickener according to the ratio shown in Table 1, heat up the solution with the thickener dissolved while stirring, and continue stirring at 100°C to 120°C for 60 minutes to disperse it evenly , continue to heat up to 200 ° C ~ 220 ° C, keep the temperature for 10 minutes and then cool down, and homogenize three times with three rollers to form a base grease. Add compound additives to it according to the compounding ratio shown in Table 1, and then stir at 100°C to 120°C for 60 minutes. Then it was cooled, homogenized with triple rollers, and degassed to obtain a grease composition.

[0025] In half of the base oils shown in Table 2, dissolve 4,4-diphenylmethane diisocyanate (hereinafter referred to as MD...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com