Manganese-lithium separating method used in ternary battery waste comprehensive recycling

A ternary battery and separation method technology, which is applied in the direction of battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of complex process, high production cost, long preparation process, etc., to simplify the preparation process and reduce energy consumption of materials The effect of reducing consumption and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

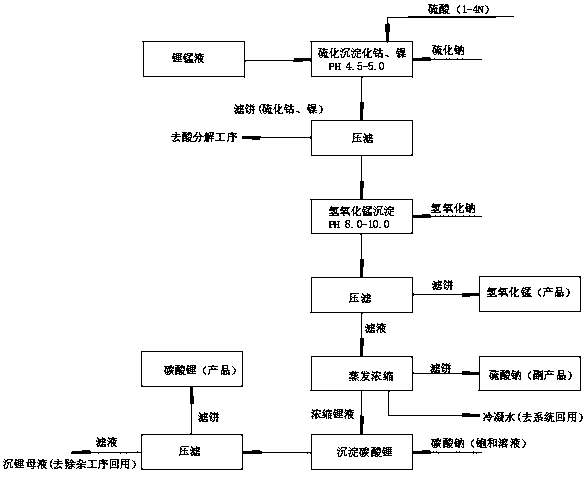

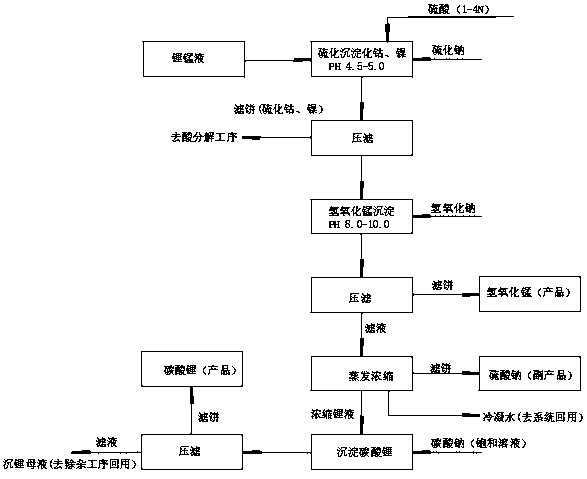

[0018] Implementation method: The manganese and lithium separation method in the comprehensive recovery of ternary battery waste is carried out as follows:

[0019] a. Waste ternary battery material powder obtained by dismantling waste ternary batteries, after acid leaching, copper removal, iron and aluminum removal, to obtain impurity removal solution, its special features are:

[0020] b. Use sodium hydroxide to adjust the pH value of the impurity removal solution to 5.5-6.5, preferably 6. Precipitate the mixture of cobalt hydroxide and nickel hydroxide, filter and wash, and the filtrate and washing liquid enter the manganese-lithium separation operation process.

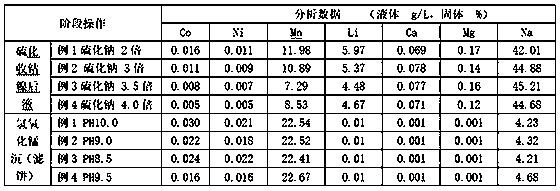

[0021] c, washing liquid and filtrate adjust pH to 4.5-5.0 with dilute sulfuric acid, by 2.0-4.0 times of cobalt and nickel total amount, preferably 2.5-3.5 times, 3 times, add solid sodium sulfide, reaction time 30-65 minutes, preferably 35-60 minutes, 40-55 minutes, 45-50 minutes, make the remaining cobalt and n...

Embodiment 1

[0029] Embodiment 1: the method for separating manganese and lithium in the comprehensive recovery of ternary battery waste, take the following steps:

[0030] a. The waste ternary battery material powder obtained by dismantling the waste ternary battery is subjected to acid leaching to remove copper, iron and aluminum to obtain a liquid for removing impurities.

[0031] b. Use 1% sodium hydroxide to adjust the pH value of the impurity removal solution to 5.5, precipitate a mixture of cobalt hydroxide and nickel hydroxide, filter and wash, and the filtrate and washing liquid enter the manganese-lithium separation operation process.

[0032] c. At 20m 3 Pump 15m into the reactor 3 Wash liquid and filtrate, adjust pH to 4.5 with 4N sulfuric acid solution, add solid sodium sulfide by 2.0 times of the total amount of cobalt and nickel, react for 30 minutes, make cobalt and nickel ions remaining in the solution form cobalt sulfide and nickel sulfide precipitation, use 60m 2 The p...

Embodiment 2

[0037] Embodiment 2: the separation of manganese and lithium in the comprehensive recovery of ternary battery waste, the following steps are taken:

[0038] a. The waste ternary battery material powder obtained by dismantling the waste ternary battery is subjected to acid leaching to remove copper, iron and aluminum to obtain a liquid for removing impurities.

[0039] b. Use 32% sodium hydroxide to adjust the pH value of the impurity removal solution to 6.5, precipitate a mixture of cobalt hydroxide and nickel hydroxide, filter and wash, and the filtrate and washing liquid enter the manganese-lithium separation operation process.

[0040] c. At 20m 3 Pump 15m into the reactor 3 Wash liquid and filtrate, use 1N sulfuric acid solution to adjust pH to 4.7, add 3.0 times solid sodium sulfide of cobalt and nickel total amount, react for 40 minutes, make cobalt nickel ion remaining in the solution form cobalt sulfide and nickel sulfide precipitation, use 60m 2 The plate and frame ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap