A kind of electrochemical etchant showing the metallographic structure of SLM formed in 718 nickel-based superalloy and its application method

A nickel-based superalloy, IN718 technology, applied in the field of electrochemical etchants, can solve the problems of difficult to grasp heating temperature and heating time, excessive metallographic corrosion, high risk of acidic corrosive liquid, etc., to facilitate accurate quantitative and process optimization analysis , obvious grain boundaries, simple formula effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

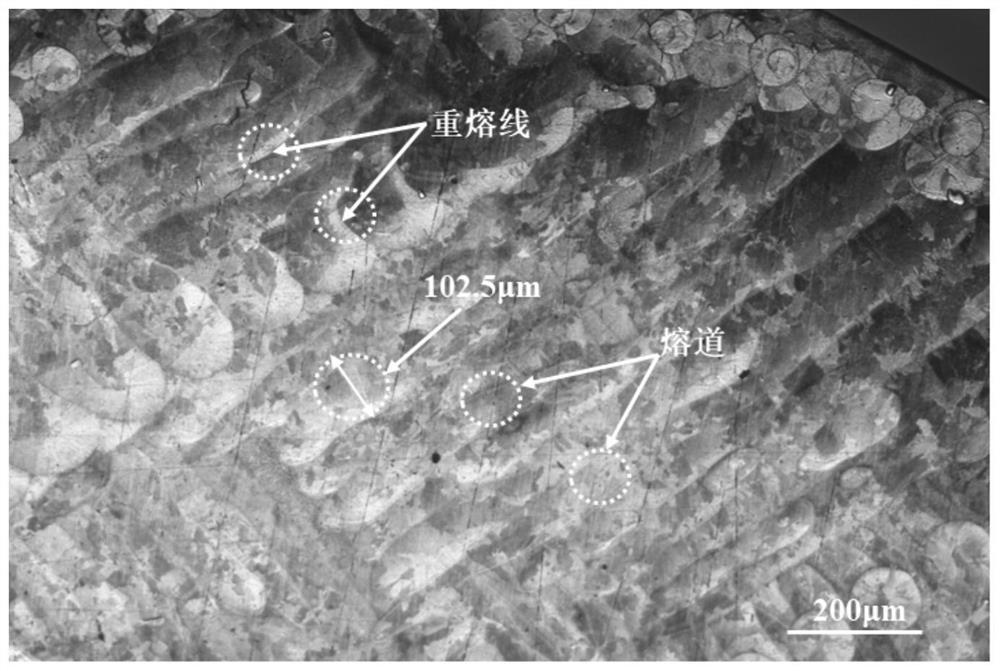

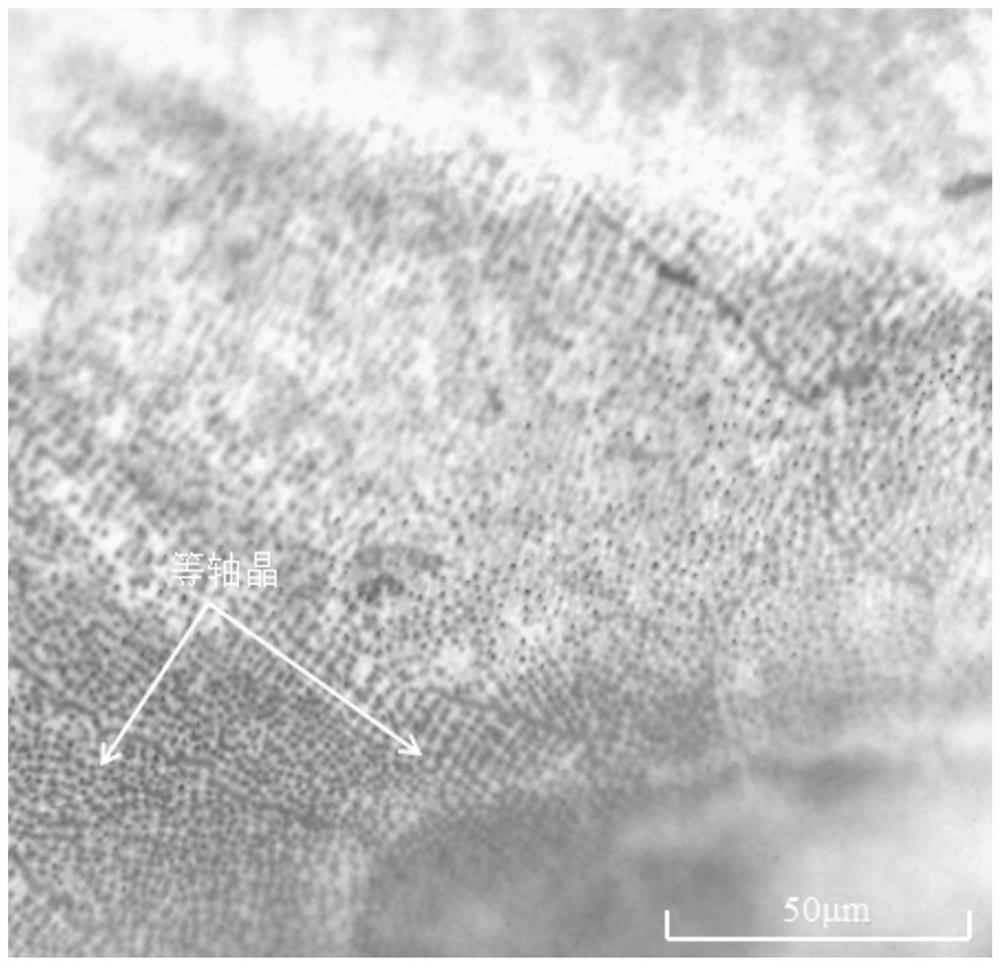

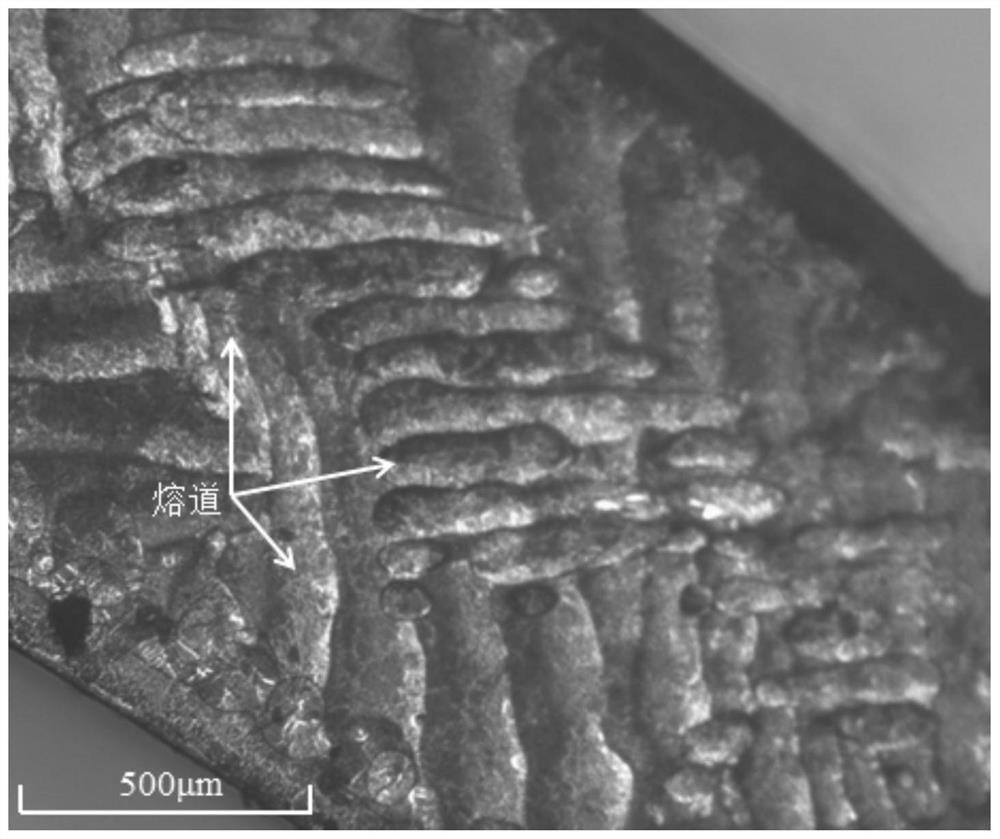

Image

Examples

Embodiment 1

[0051] 1) Preparation of electrolytic corrosion agent: pipette 10ml of perchloric acid solution and 90ml of absolute ethanol solution, and pour the perchloric acid solution into absolute ethanol solution at room temperature to prepare 100ml of mixed solution;

[0052] 2) Preparation of cold chemical etchant: pipette 8ml of concentrated nitric acid solution, 24ml of concentrated hydrochloric acid solution, slowly pour the concentrated nitric acid solution into the concentrated hydrochloric acid solution at room temperature and keep stirring to prepare 32ml of mixed solution;

[0053] 3) Select the top surface, bottom surface, and side surface of the SLM-molded IN 718 sample, and polish them with 100#, 320#, 600#, 800#, 1000#, 2000# and 3000# specifications of water-grinding sandpaper;

[0054] 4) Use a mechanical polishing machine to perform rough polishing and fine polishing on the top surface, bottom surface, and side surface of the shaped sample polished in step 3). The polis...

Embodiment 2

[0062] 1) Preparation of electrolytic corrosion agent: pipette 20ml of perchloric acid solution and 80ml of absolute ethanol solution, and pour the perchloric acid solution into the absolute ethanol solution at room temperature to prepare 100ml of mixed solution;

[0063] 2) Preparation of cold chemical etchant: pipette 10ml of concentrated nitric acid solution, 30ml of concentrated hydrochloric acid solution, slowly pour the concentrated nitric acid solution into the concentrated hydrochloric acid solution at room temperature and keep stirring to prepare 40ml of mixed solution;

[0064] 3) Select the top surface, bottom surface, and side surface of the SLM-molded IN 718 sample, and polish them with 100#, 320#, 600#, 800#, 1000#, 2000# and 3000# specifications of water-grinding sandpaper;

[0065]4) Use a mechanical polishing machine to perform rough polishing and fine polishing on the top surface, bottom surface, and side surface of the shaped sample polished in step 3). The p...

Embodiment 3

[0073] 1) Preparation of electrolytic corrosion agent: pipette 15ml of perchloric acid solution and 85ml of absolute ethanol solution, and pour the perchloric acid solution into absolute ethanol solution at room temperature to prepare 100ml of mixed solution;

[0074] 2) Preparation of cold chemical etchant: pipette 9ml of concentrated nitric acid solution, 27ml of concentrated hydrochloric acid solution, slowly pour the concentrated nitric acid solution into the concentrated hydrochloric acid solution at room temperature and keep stirring to prepare 36ml of mixed solution;

[0075] 3) Select the top surface, bottom surface, and side surface of the SLM-molded IN 718 sample, and polish them with 100#, 320#, 600#, 800#, 1000#, 2000# and 3000# specifications of water-grinding sandpaper;

[0076] 4) Use a mechanical polishing machine to perform rough polishing and fine polishing on the top surface, bottom surface, and side surface of the shaped sample polished in step 3). The polis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com