A kind of high elastic shrinkage yarn and preparation method thereof

A high-elasticity, shrinking technology, applied in the direction of filament/thread forming, rayon heat treatment, conjugated synthetic polymer rayon, etc., can solve the problems of stress concentration, insufficient moisture absorption and quick-drying performance, and reach the application range. Wide, increase the effect of moisture absorption and quick-drying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of preparation method of high elastic shrinkage yarn, its process is as follows:

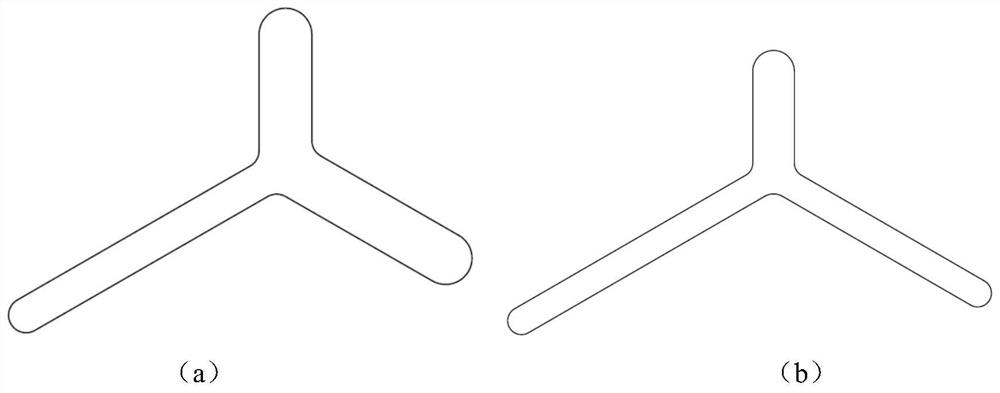

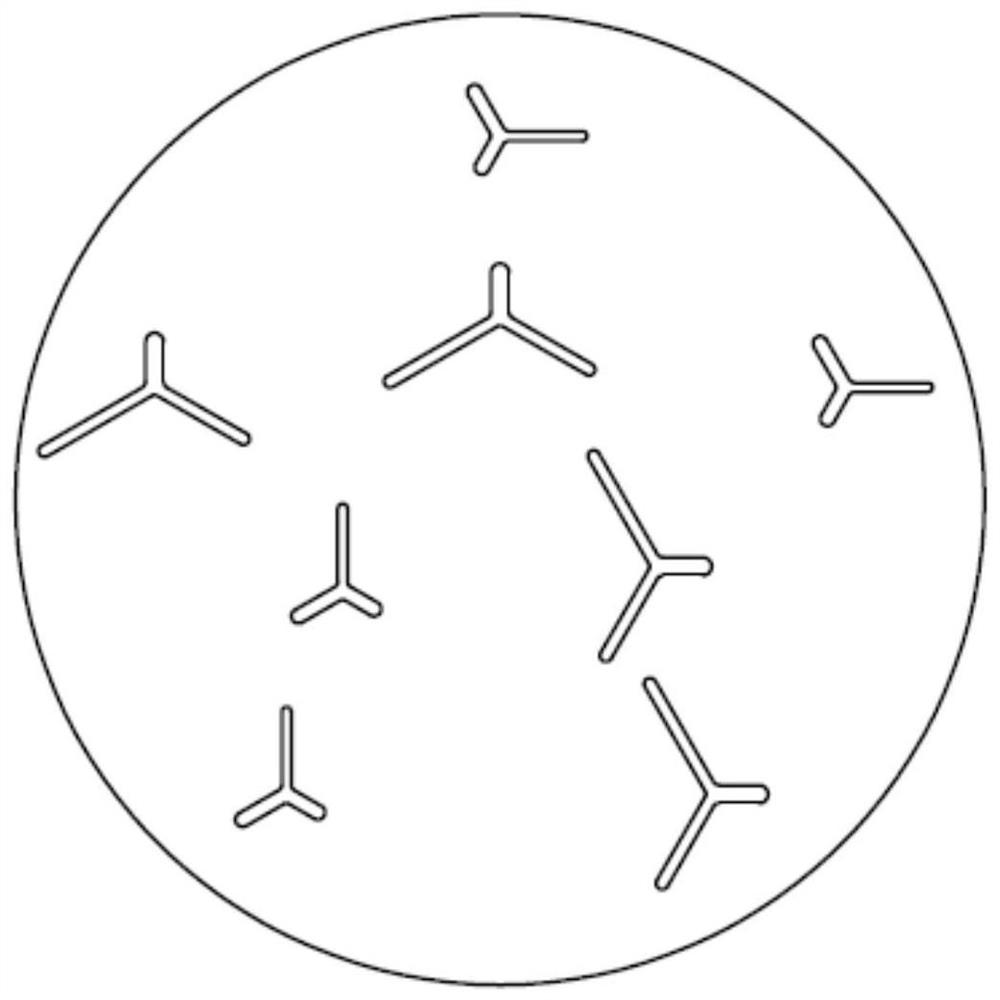

[0036](1) FDY filaments are prepared from PET (intrinsic viscosity 0.55dL / g) and PBT (intrinsic viscosity 1.13dL / g) with a mass ratio of 40:60 according to the FDY process and the spinning process of circular sheath-core composite fibers , change the spinneret hole on the spinneret from circular to trilobal, and the trilobal spinneret is divided into two categories:

[0037] The ratio of the length of the three leaves of the first type of three-lobed spinneret hole is 1.0:1.1:2.5, the ratio of the corresponding three-leaf width is 1.5:1.5:1, and the ratio of the length and width of the shortest leaf is 2.7:1. The angle between the centerlines of two adjacent lobes is 120°;

[0038] The ratio of the length of the three leaves of the second type of three-lobed spinneret hole is 1.0:1.7:2.4 and the two long leaves are not equal in length. The corresponding ratio of the width of the t...

Embodiment 2

[0044] A kind of preparation method of high elastic shrinkage yarn, its process is as follows:

[0045] (1) FDY filaments are prepared according to the FDY process and the process of spinning circular sheath-core composite fibers from PET (intrinsic viscosity is 0.5dL / g) and PBT (intrinsic viscosity is 1dL / g) with a mass ratio of 30:70, Change the spinneret hole on the spinneret plate from circular to trilobal, and the trilobal spinneret is divided into two categories:

[0046] The ratio of the length of the three leaves of the first type of three-lobed spinneret hole is 1.0:1.2:2.5, the ratio of the corresponding three-leaf width is 1.5:1.5:1, and the ratio of the length and width of the shortest leaf is 2.5:1. The angle between the centerlines of two adjacent lobes is 120°;

[0047] The ratio of the length of the three leaves of the second type of three-leaf spinneret is 1.0:1.7:2.3 and the two long leaves are not equal in length. The corresponding ratio of the width of the...

Embodiment 3

[0053] A kind of preparation method of high elastic shrinkage yarn, its process is as follows:

[0054] (1) FDY filaments are prepared from PET (intrinsic viscosity 0.58dL / g) and PBT (intrinsic viscosity 1.2dL / g) with a mass ratio of 70:30 according to the FDY process and the spinning process of circular sheath-core composite fibers , change the spinneret hole on the spinneret from circular to trilobal, and the trilobal spinneret is divided into two categories:

[0055] The ratio of the length of the three leaves of the first type of three-lobed spinneret hole is 1.0:1.1:2.0, the ratio of the corresponding three-leaf width is 1.5:1.5:1, and the ratio of the length and width of the shortest leaf is 3.5:1. The angle between the centerlines of two adjacent lobes is 120°;

[0056] The ratio of the length of the three leaves of the second type of three-lobed spinneret hole is 1.0:1.6:2.2 and the two long leaves are not equal in length. The corresponding ratio of the width of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com