Production method for quick-dry fabric

A production method and fabric technology, applied in the direction of enzyme/microbial biochemical treatment, biochemical fiber treatment, fiber type, etc., can solve the problems that clothes are easily stained on the body surface, polyester fiber has poor hygroscopicity, and sweat cannot be effectively discharged. To achieve the effect of enhancing moisture absorption, enhancing moisture absorption performance, and enhancing moisture absorption and quick-drying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

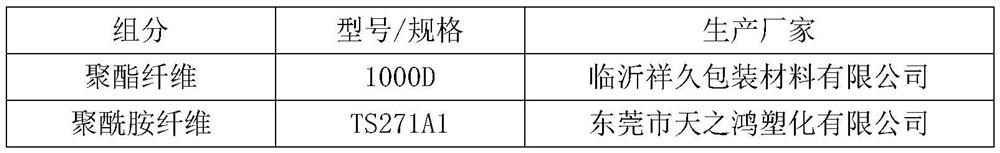

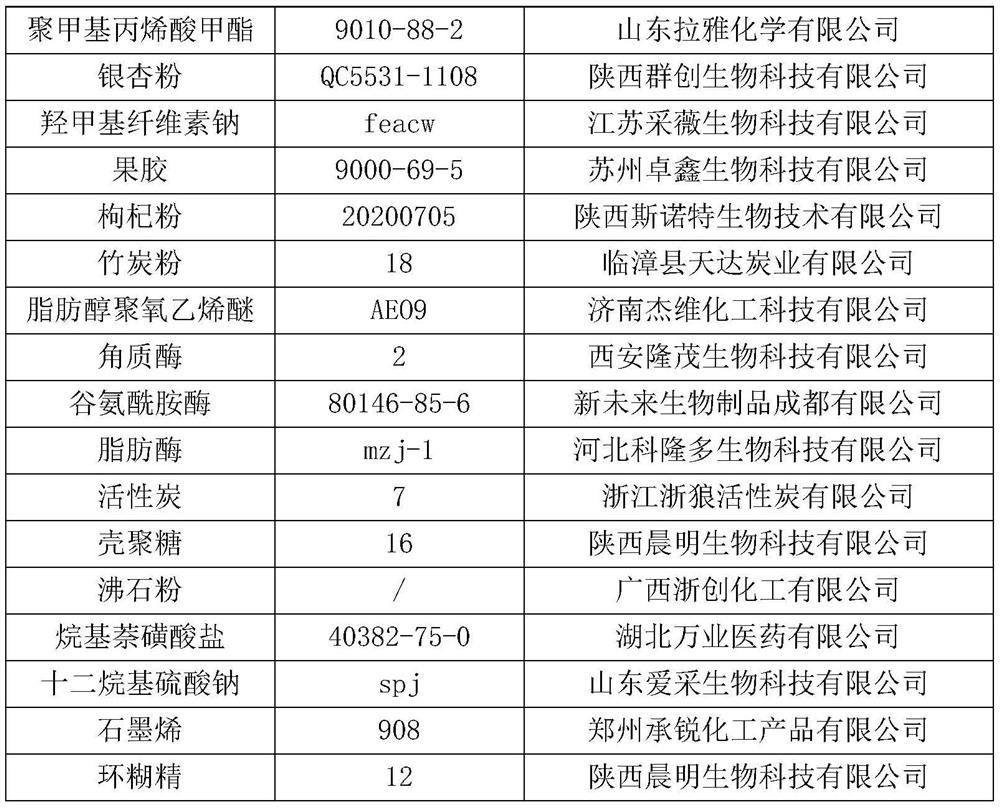

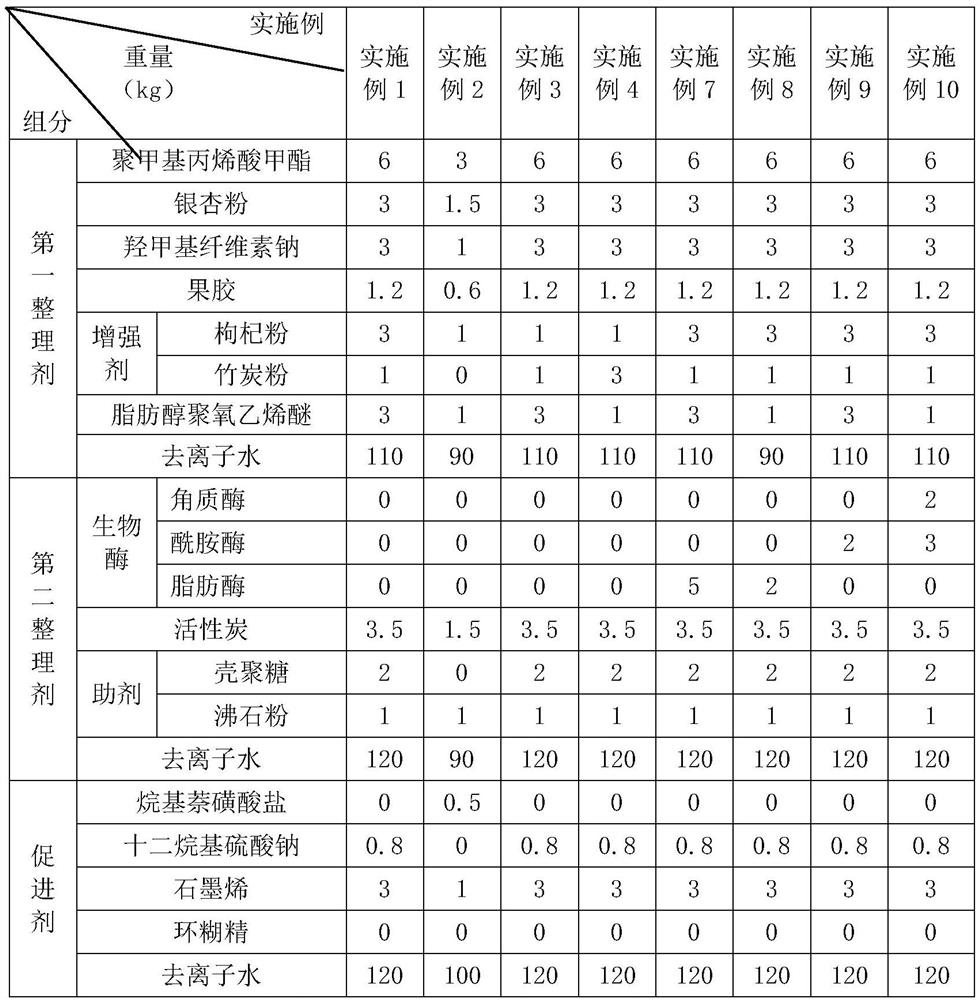

[0054] A kind of production method of quick-drying fabric, included concrete component and weight are as shown in table 2, comprises the following steps:

[0055] S1: mix and stir polymethyl methacrylate, ginkgo powder, sodium hydroxymethyl cellulose, pectin, reinforcing agent, polyoxyethylene ether (polyoxyethylene ether is fatty alcohol polyoxyethylene ether) and deionized water, The stirring speed is 800r / min, and the first treatment agent is obtained by stirring evenly; the activated carbon, the auxiliary agent and deionized water are mixed and stirred, and the stirring speed is 900r / min, and the second treatment agent is obtained after stirring; the sodium lauryl sulfate , graphene, and deionized water are mixed and stirred at a stirring speed of 900r / min, and the accelerator is obtained after stirring evenly;

[0056] S2: adopt the first treating agent to carry out padding treatment to polyester fiber, the padding time is 40min, obtains the polyester fiber after pretreat...

Embodiment 2

[0060] Embodiment 2: a kind of production method of quick-drying fabric, the difference with embodiment 1 is that the components and the weight of the first treatment agent, the second treatment agent and the accelerator are different, and the specific components and weight included are as shown in the table 2.

Embodiment 3-4

[0061]Embodiment 3-4: a kind of production method of quick-drying fabric, the difference with embodiment 1 is that the specific components and weight of reinforcing agent are different, and the specific components and weight that comprise are as shown in table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com