Lattice anti-rockfall structure of large ultrahigh karst cavity tunnel and construction method

A technology of tunnel structure and lattice structure, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., to achieve the effect of simple construction method, favorable promotion and high height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

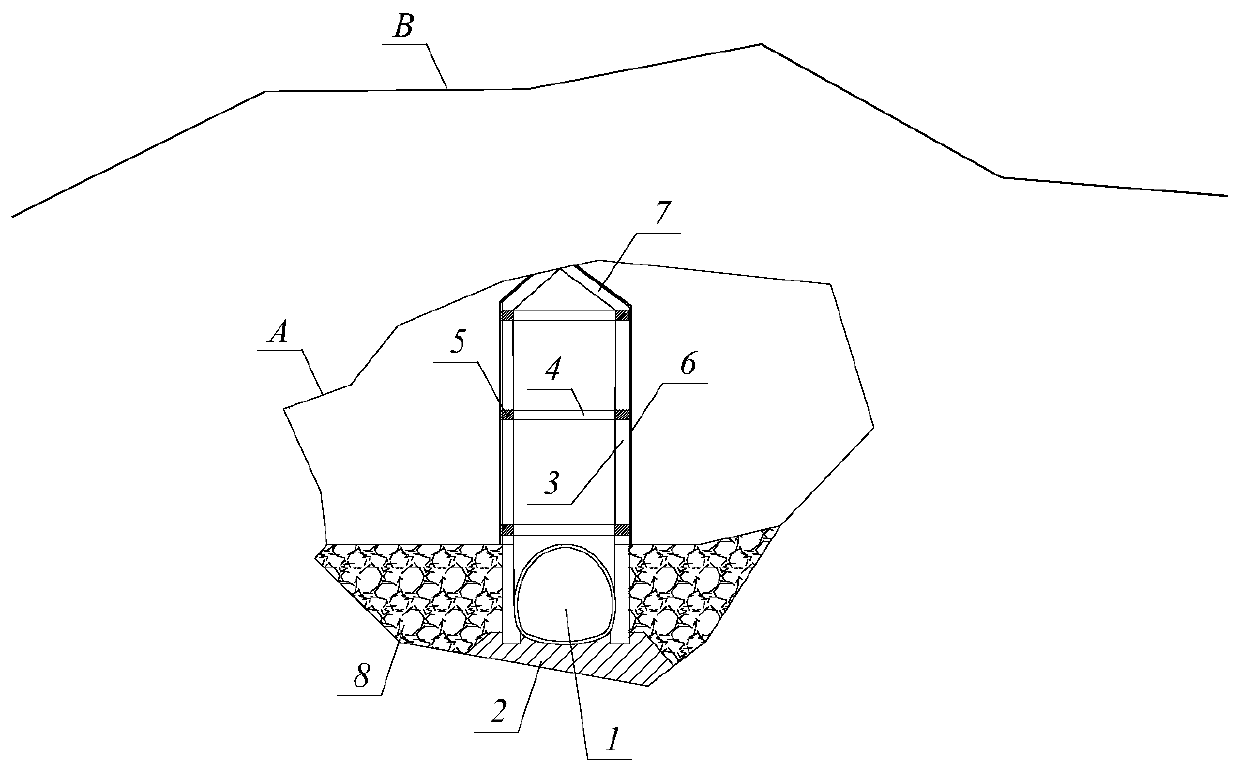

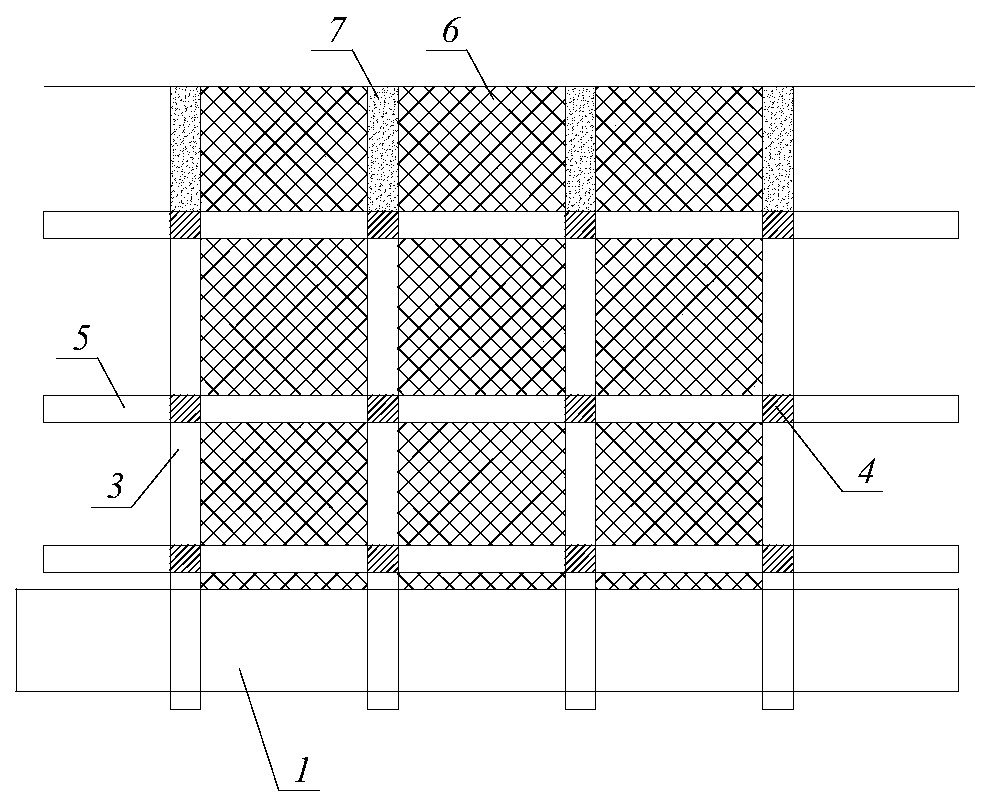

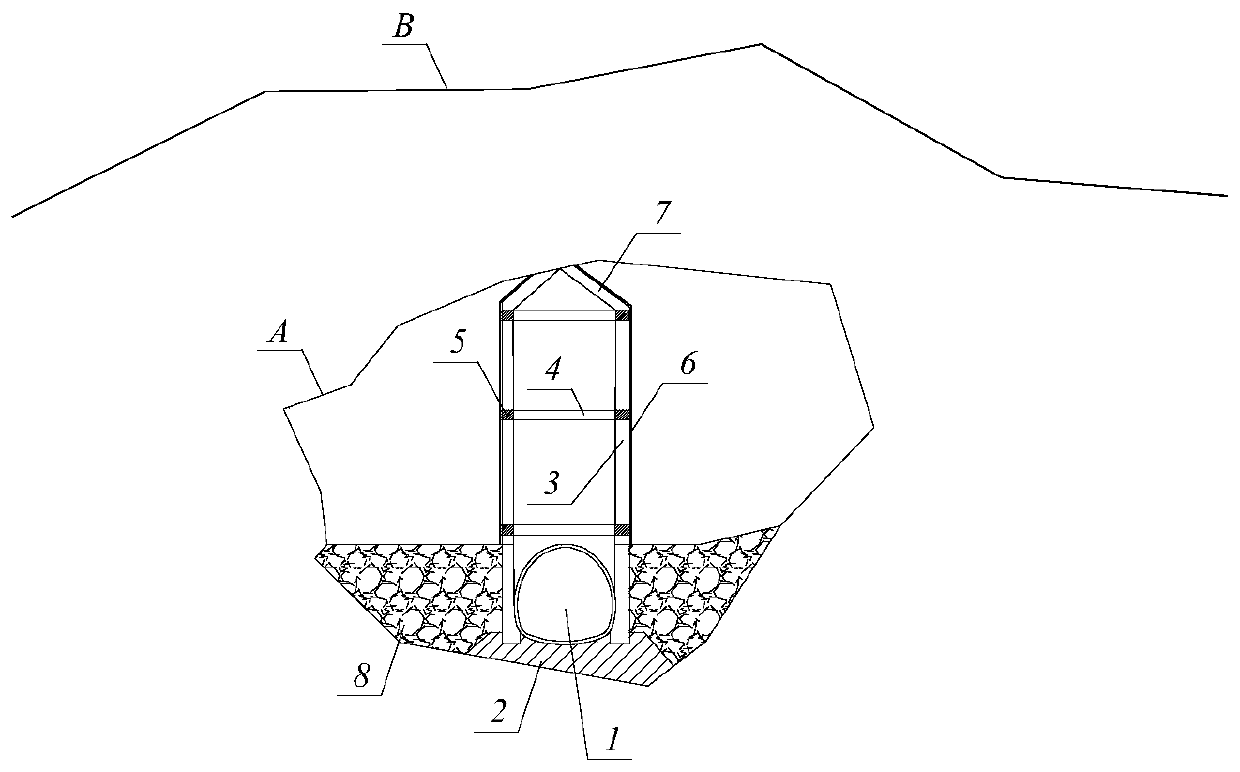

[0024] refer to figure 1 , a large-scale ultra-high karst cavity tunnel lattice type anti-rockfall structure of the present invention, including a tunnel structure 1 passing through the ultra-high karst cavity, the tunnel structure 1 is integrally poured with reinforced concrete, and the bottom is located on the stable bedrock surface On the tunnel foundation 2 above, an integral reinforced concrete frame structure spanning the tunnel structure 1 and extending longitudinally along the line is set on the tunnel foundation 2. The upper part of the reinforced concrete frame structure is triangular, and the top is connected to the roof of the karst cavity. The outer side of the integral reinforced concrete frame structure is tightly wrapped and installed with a passive protective net 6; the lateral sides of the tunnel structure 1 are filled with tunnel dregs A c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap