System and method for dynamic monitoring of water pressure and flow velocity behind tunnel lining and dredging and drainage

A dynamic monitoring and drainage system technology, applied in drainage, earth square drilling, mining equipment, etc., can solve the problems of small blind pipe coverage area, difficulty in finding the blocked location of drainage pipes, and reduced drainage capacity, so as to achieve easy operation and maintenance, and realize Operation and maintenance, and the effect of improving drainage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

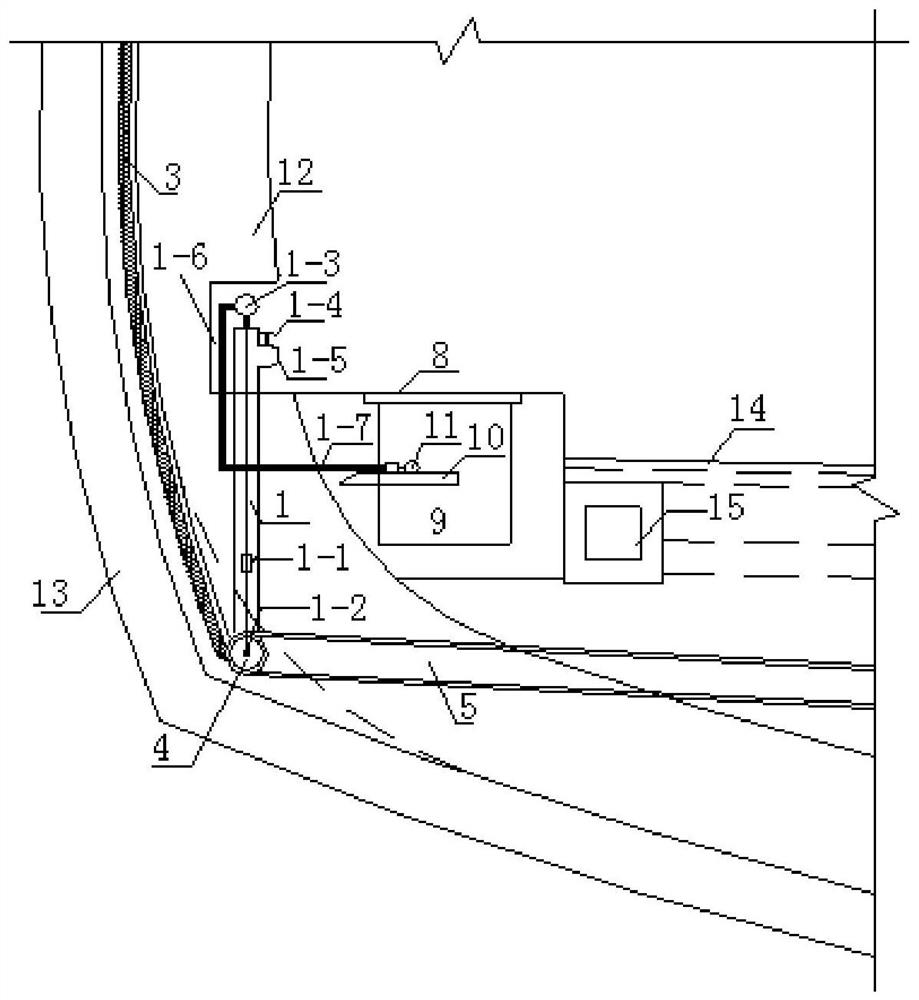

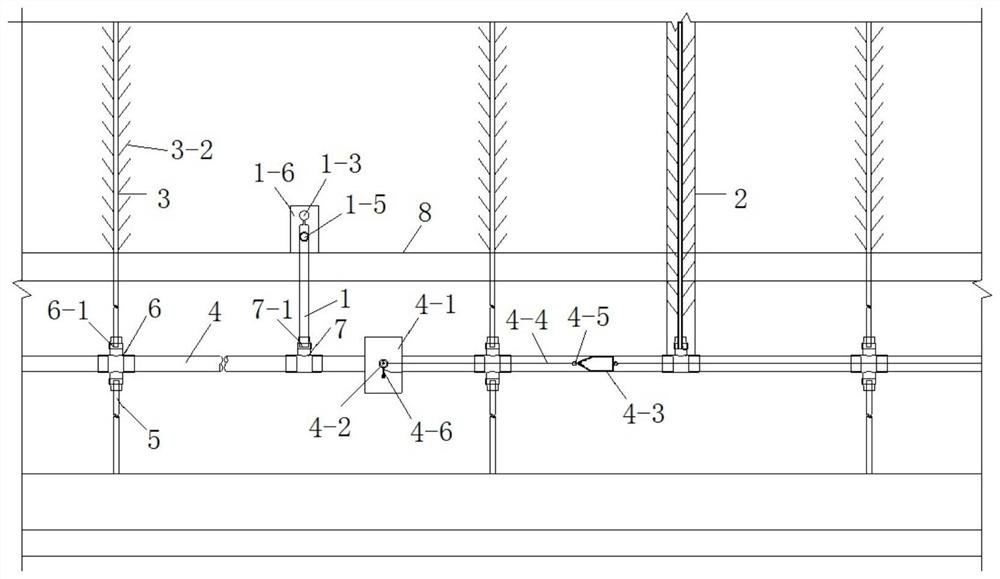

[0061] Such as figure 1 with figure 2 As shown, the water pressure and flow velocity dynamic monitoring and drainage system behind the tunnel lining implemented in this implementation is composed of a circular diversion drainage system, a water pressure-flow velocity monitoring system, a longitudinal drainage system, a horizontal drainage system, and a drainage system. Drainage system, horizontal drainage system, water pressure-flow velocity monitoring system 1 can be connected with vertical drainage pipe through four-way 6 or three-way 7 .

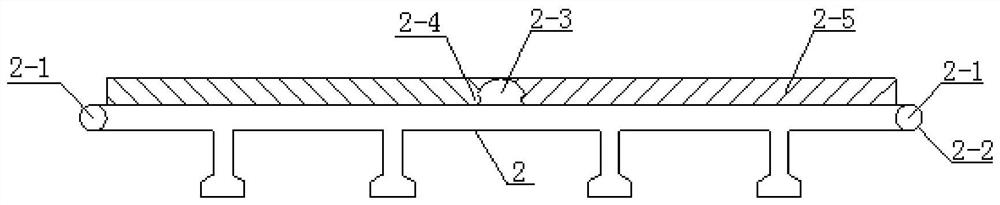

[0062] Such as Figure 5 with Image 6 As shown, the circumferential drainage system is composed of a back-mounted waterstop 2 and a circumferential drainage pipe 3, and several circumferential drainage pipes 3, such as 2, 3, 4, 5 or more, according to the tunnel The length and the specific construction environment determine the specific quantity, distributed in the length direction of the tunnel, and each circumferential drain pipe 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com