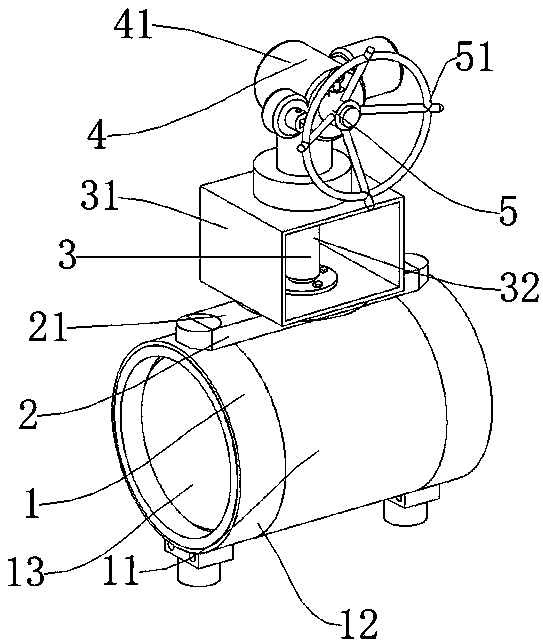

Safety quickly adjusted pipeline butterfly valve

A technology for adjusting pipelines and safety. It is applied in the directions of lift valves, valve details, valve devices, etc. It can solve the problems of single control effect, no tight closure, insufficient sealing of butterfly valves, etc., and achieve the effect of ensuring the sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

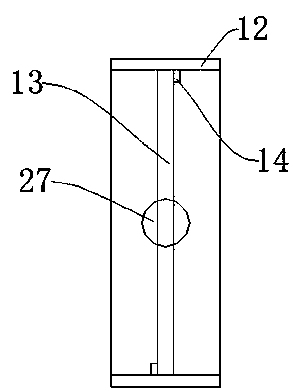

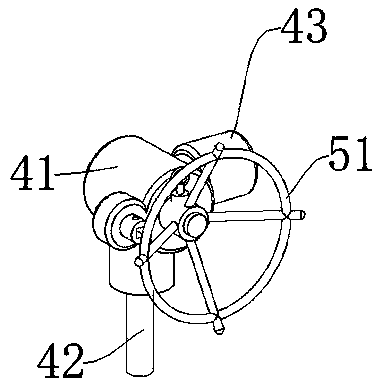

[0045] Such as Figure 1-Figure 7 As shown, the transmission mechanism 2 includes a sealing box 21, a first transmission gear 22, a second transmission gear 23, and a transmission shaft 24. The sealing box 21 is connected to the support frame 31 of the valve body mechanism 1 connecting the cylinder 11 and the support mechanism 3, and the sealing box 21 Inside is provided with a first transmission gear 22, the first transmission gear 22 is connected to the output shaft 42 of the power mechanism 4, the lower end of the first transmission gear 22 is connected to the second transmission gear 23, and the key on the second transmission gear 23 is connected to the transmission shaft 24, the transmission shaft Both ends of 24 are keyed to the third transmission gear 25, the lower end of the third transmission gear 25 is connected to the fourth transmission gear 26, the fourth transmission gear 26 is connected to the rotating shaft 27, and the rotating shaft 27 is connected to the valve...

Embodiment 2

[0048] The difference between this embodiment and embodiment 1 is:

[0049] Such as Figure 8 The transmission mechanism 2 includes a sealed box 21, a first linkage block 211, a linkage plate 212, and a fixed pin 213. Two first linkage blocks 211 are arranged inside the seal box 21, and the first linkage block 211 is connected to the output shaft 42 of the power mechanism 4. , the output end of the first linkage block 211 is keyed to the linkage plate 212, and one end of the linkage plate 212 is connected to the second linkage plate 214, between the first linkage block 211 and the linkage plate 212, and between the linkage plate 212 and the second linkage plate 214 through The fixed pin 213 is connected, the second linkage plate 214 is connected to the rotating shaft 27, the rotating shaft 27 is connected to the valve body plate 13 of the valve body mechanism 1, the output shaft 42 drives the first linkage block 211, and the two first linkage blocks 211 drive the linkage plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com