Double-pipe full-automatic layered inclinometer system and inclinometer method

A technology of inclinometer and inclinometer tube, which is applied in the direction of signal transmission system, general control system, control/adjustment system, etc. It can solve the problems of human error in measurement data, large labor cost, and large interference of construction operations, etc., and achieve the elimination of instrument error, high degree of automation, and the effect of eliminating zero drift of the probe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

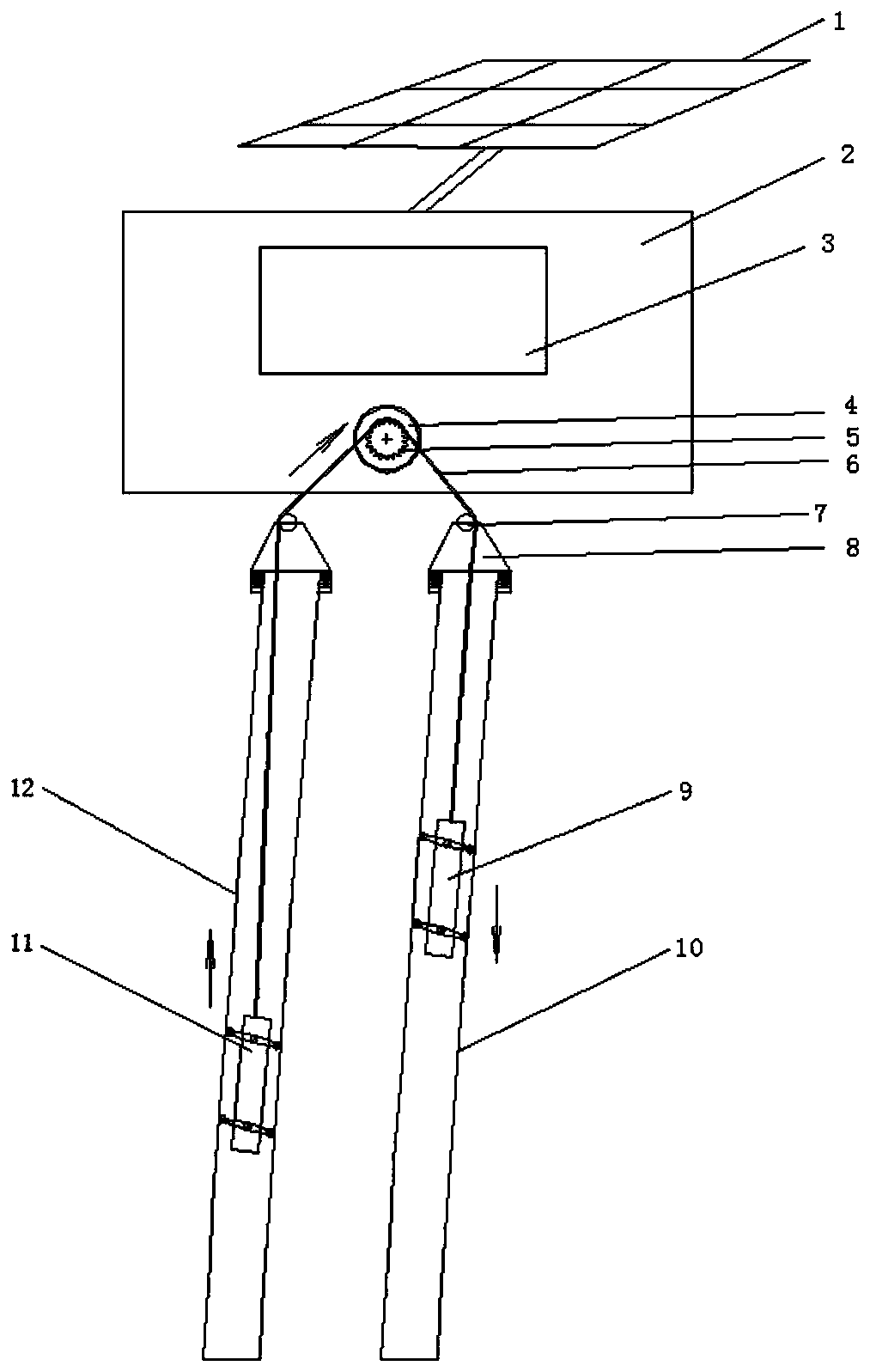

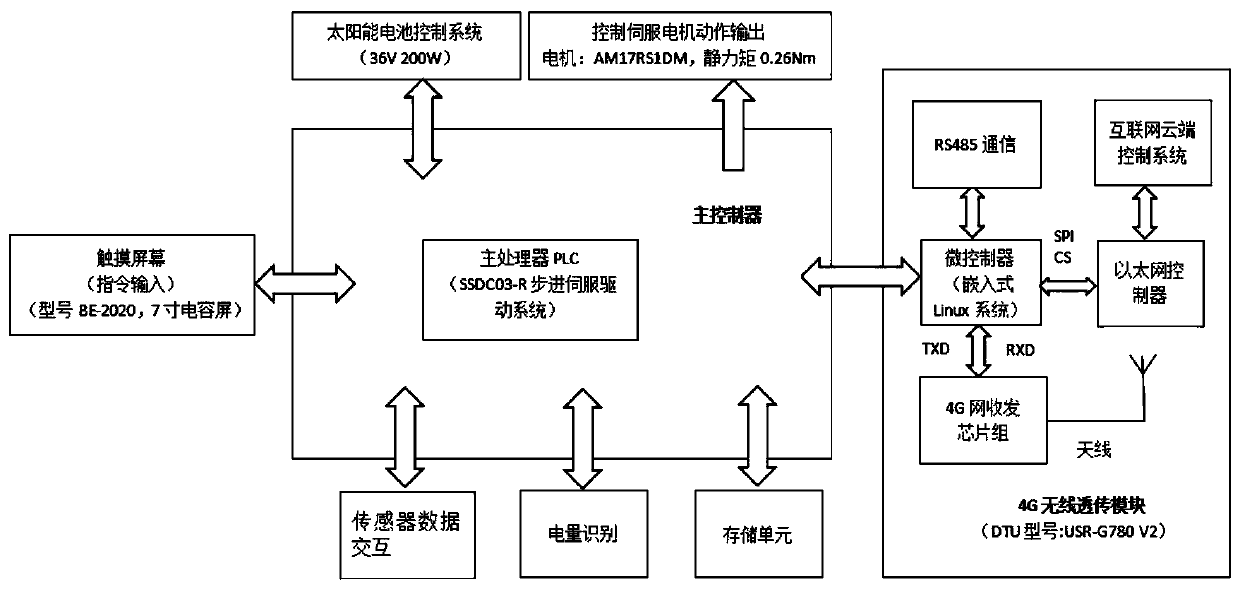

[0032] A double-tube horizontal displacement layered inclinometer system, including A and B two inclinometer tubes 10.12, A and B two high-precision inclinometer probes 9.11, concentric pipe head bracket 8, servo motor 4, synchronous reduction wheel set 5. Timing belt 6 and controller.

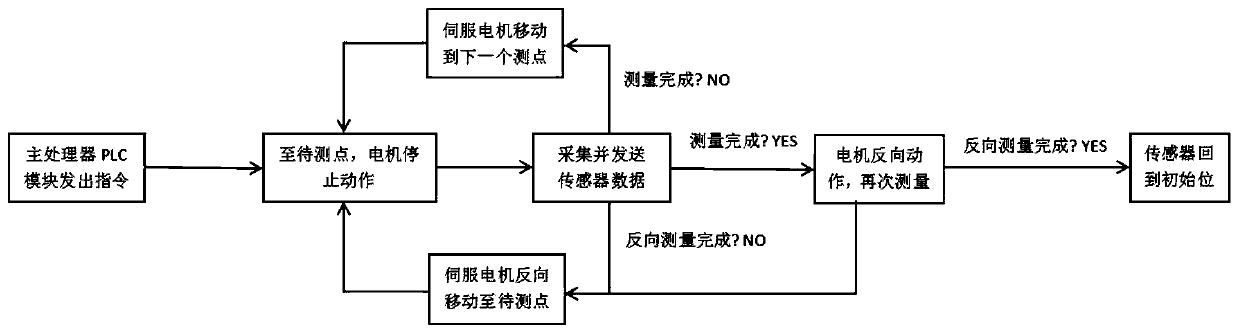

[0033] The two inclinometer tubes A and B are arranged in parallel at intervals, and the tube distance is 1.0m. A certain pulley 7 is installed on the top nozzles of the two inclinometer tubes A and B respectively through a concentric tube head bracket. The two synchronous belts The ends of the belt bypass two fixed pulleys and penetrate into the two inclinometer tubes A and B, and are respectively connected to the two high-precision inclinometer probes A an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com