Batch transfer method of micro-elements

A transfer method and micro-component technology, which is applied in the manufacture of electrical components, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems of large growth density and huge transfer quantity, and achieve high transfer efficiency, simple transfer equipment, and difficult transfer process low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical solution and effect of the present application more clear and definite, the present application will be further described in detail below with reference to the accompanying drawings and examples.

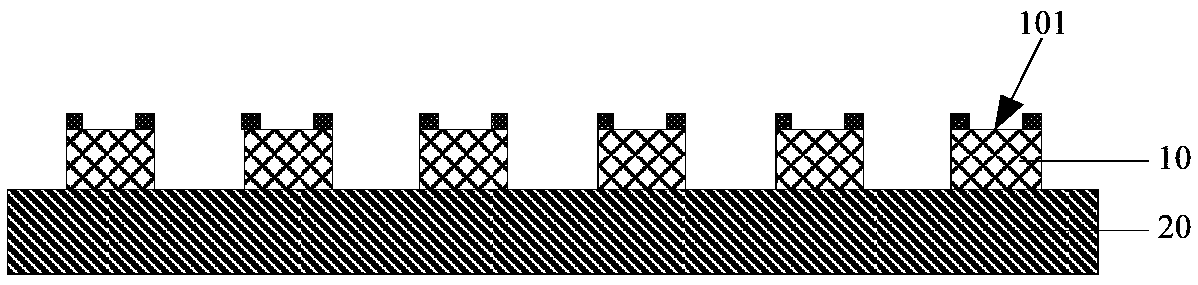

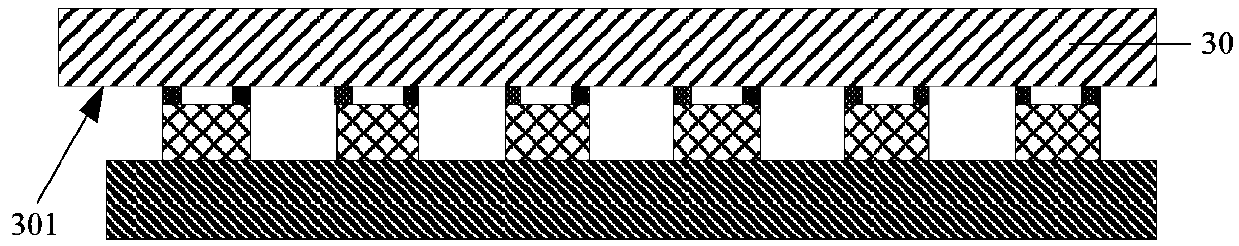

[0033] The present application provides a method for transferring micro components in batches, using two transfer substrates as transfer equipment, and transferring the micro components to the target substrate in two steps. In this way, the entire transfer process does not require the use of transfer heads and complicated transfer equipment, which greatly simplifies the difficulty of transfer. The batch transfer method disclosed in this application can be used to transfer micro-light-emitting diode devices (Micro-LED). Here, the transfer of Micro-LED is taken as an example for illustration, but it is not limited to this device, and can also be used for transfer of other micro components.

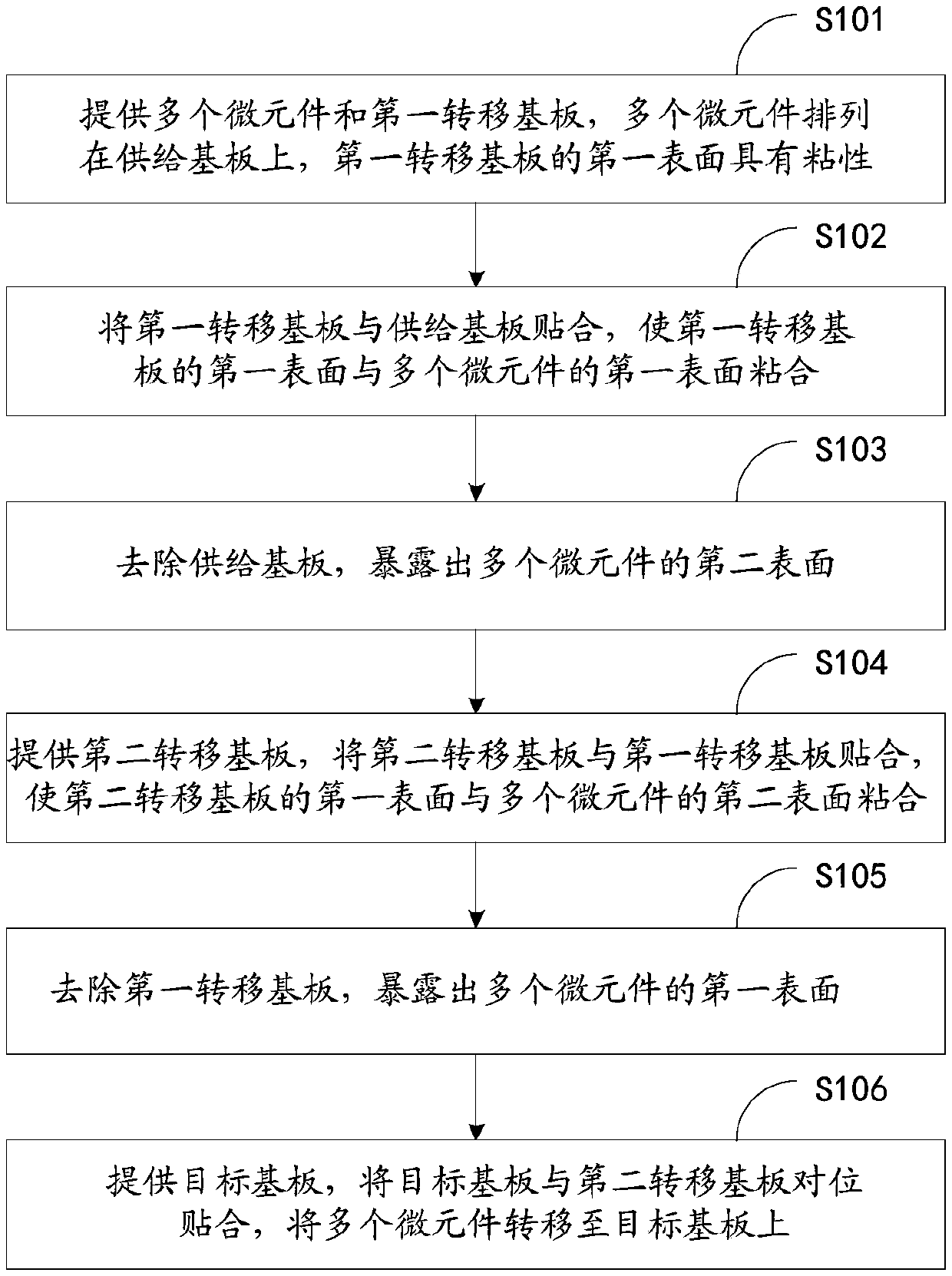

[0034] see figure 1 , figure 1 It is a schema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com