Preparation method of lithium iron phosphate material

A lithium iron phosphate and slurry technology, applied in the field of materials, can solve the problems of low carbon residual rate of polymer carbonization, difficulty in forming a uniform and dense carbon coating layer, fracture, etc., and achieves improved anti-aging ability, low cost and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of a lithium iron phosphate material in a specific embodiment of the present invention comprises the following steps:

[0033] Step S1: Mix the iron source, lithium source, and phosphorus source with the solvent according to the preset molar ratio to form a slurry, then add the first preset mass ratio of the polymer carbon source, stir and coarsely grind to form a lithium iron phosphate precursor slurry. in,

[0034] The iron source includes one of ferric phosphate, ferrous oxalate, and ferric oxide, the lithium source includes one or both of lithium carbonate, lithium hydroxide monohydrate, and lithium acetate, and the phosphorus source includes phosphoric acid One of lithium dihydrogen and ammonium dihydrogen phosphate; the solvent is one or more of water, absolute ethanol, and acetone. The preset molar ratio of the iron source, lithium source, and phosphorus source is that the molar ratio of the iron element, lithium element, and phosphorus ele...

Embodiment 1

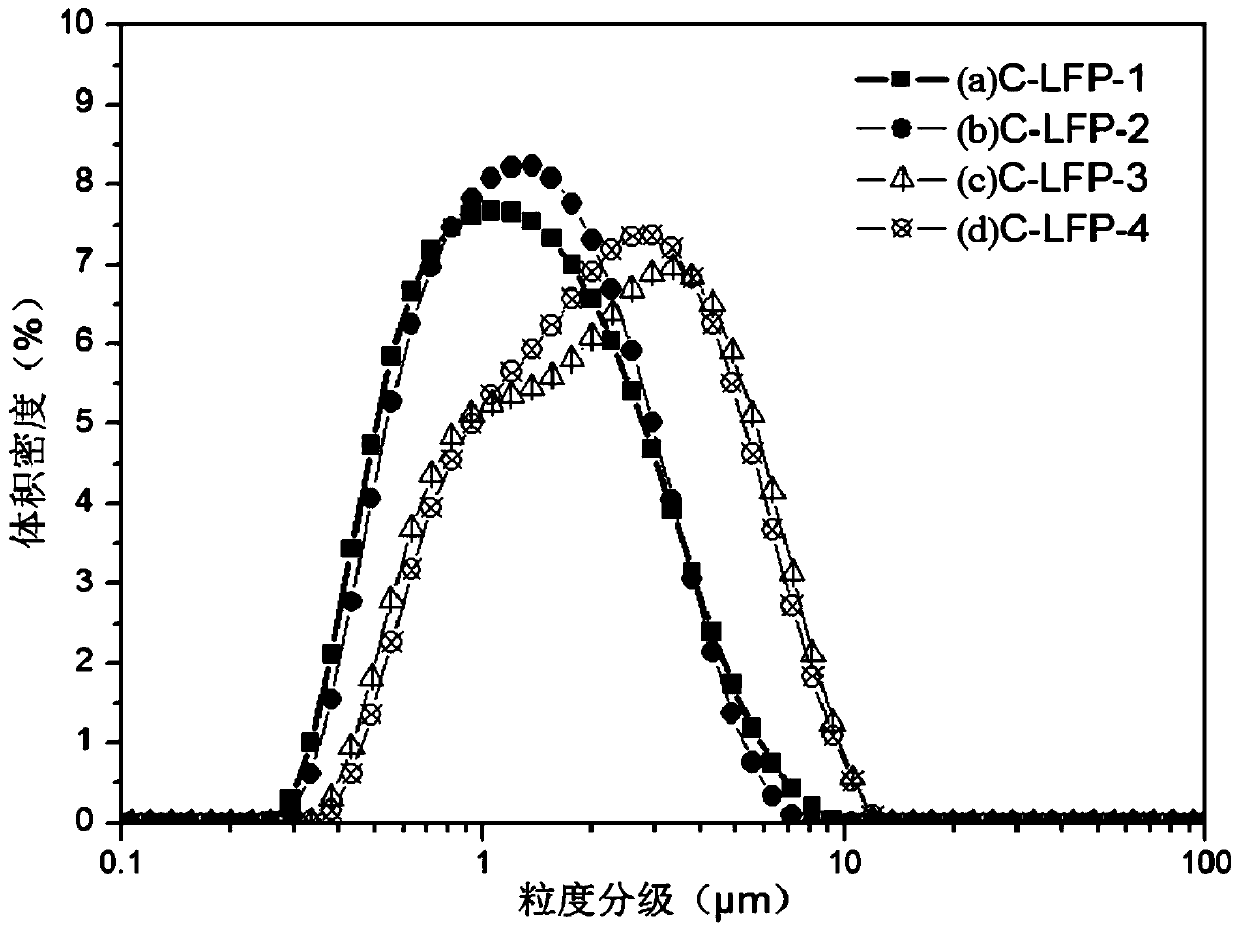

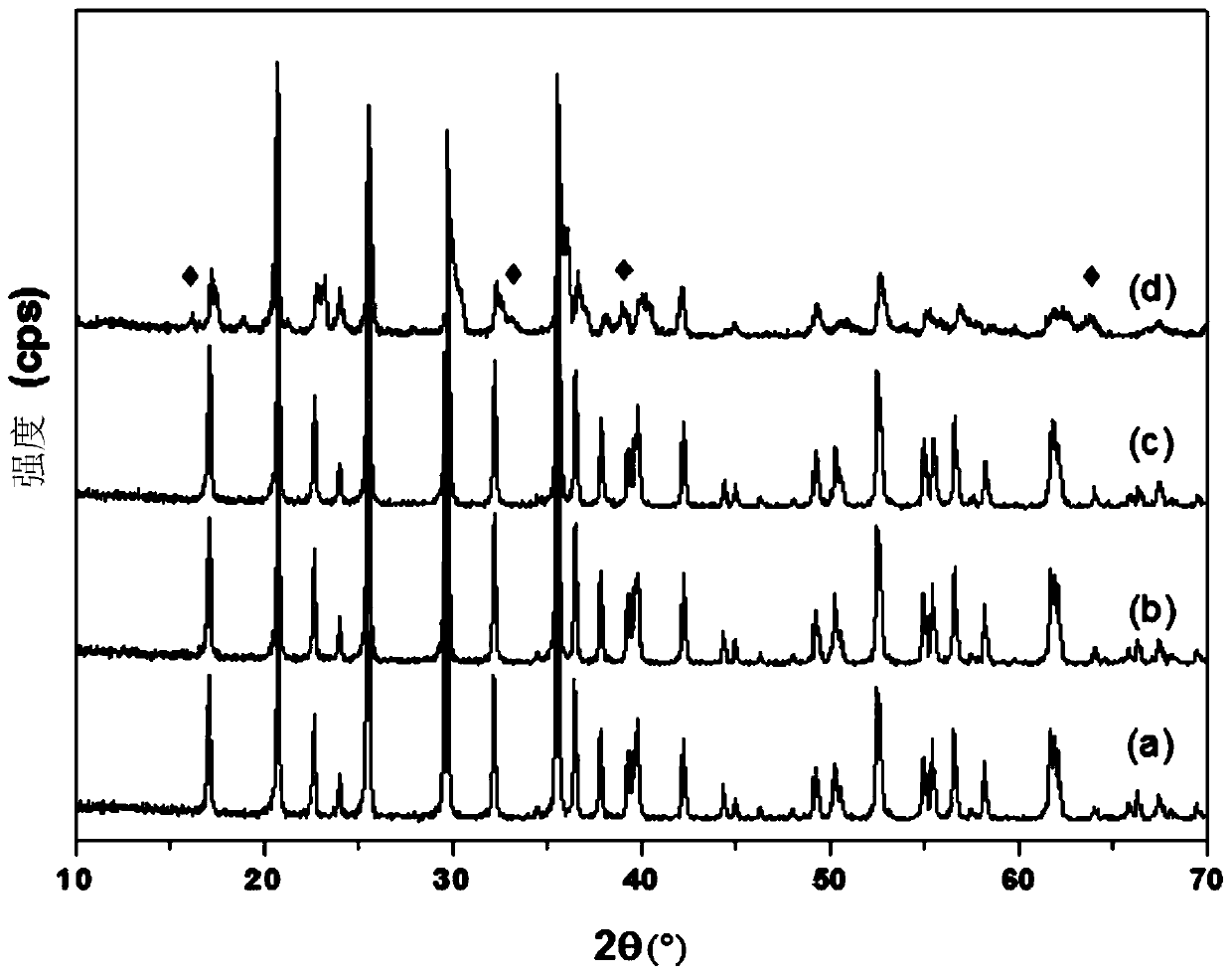

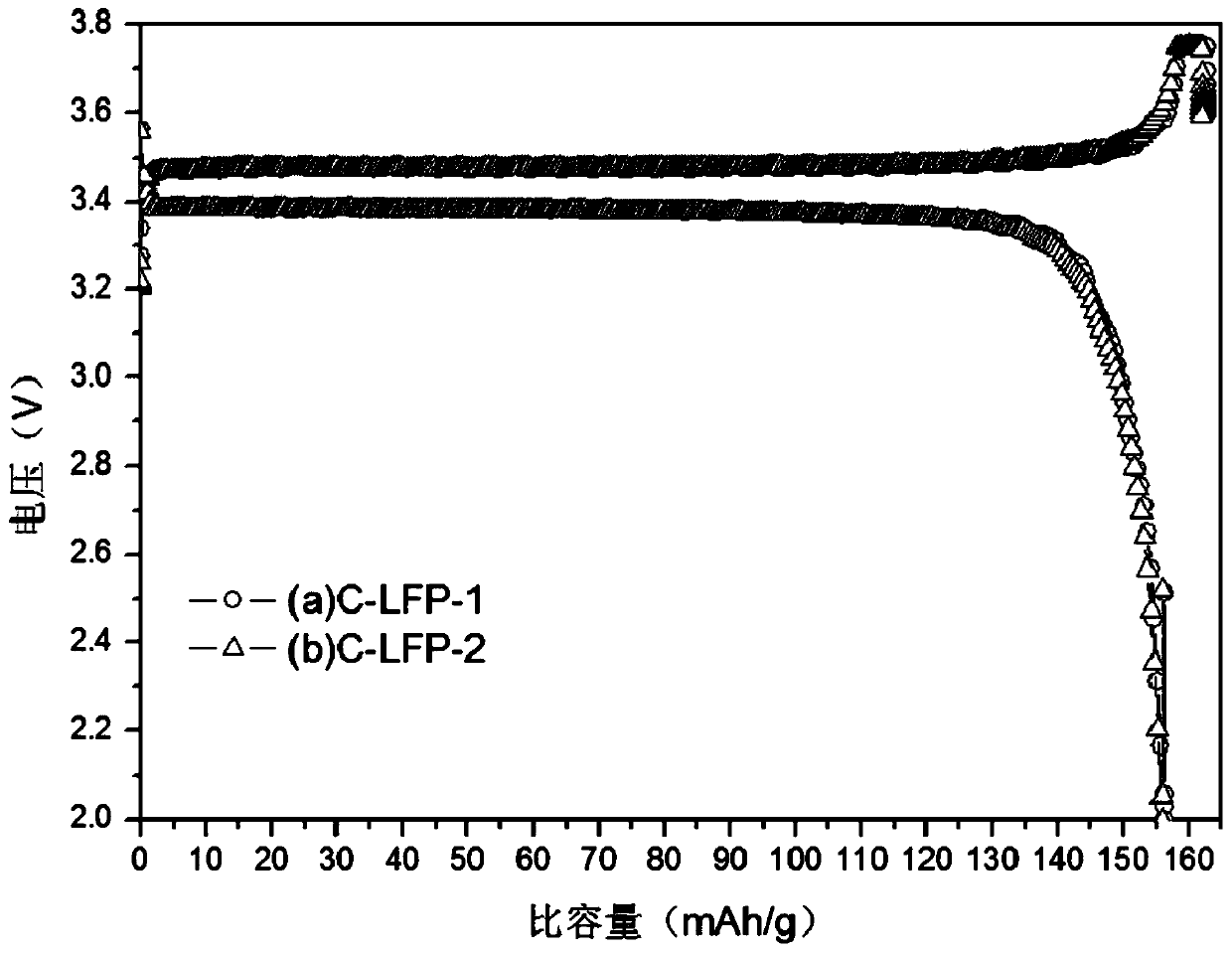

[0043] Embodiment 1: Get 500g anhydrous ferric phosphate and 125g lithium carbonate and join in the aqueous solution, add 50g polyvinyl alcohol (PVA) and grind 2h at high speed in ball mill, add 35g glucose again after being dispersed evenly, use superfine grinder to carry out fully After grinding for 2 hours, the median particle size of the slurry is controlled at 0.2-1.0 μm to obtain a precursor slurry. The above slurry is then dehydrated by a centrifugal spray dryer to obtain lithium iron phosphate precursor particles. Put the precursor particles into a tube furnace, and in a nitrogen atmosphere of 15mL / min, raise the temperature to 350°C at a rate of 5°C / min and keep it for 3h, then raise the temperature to 700°C at the same rate and keep it for 12h, and finally in the same nitrogen atmosphere Lower the temperature to room temperature, take out the cooled lithium iron phosphate and pulverize it with a jet mill to obtain a lithium iron phosphate positive electrode material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median granularity | aaaaa | aaaaa |

| Median granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com