A double-sided honeycomb powder feeding machine

A honeycomb, bilateral technology, applied in beekeeping, application, animal husbandry, etc., can solve the problem of high labor intensity, and achieve the effect of reducing labor intensity and manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

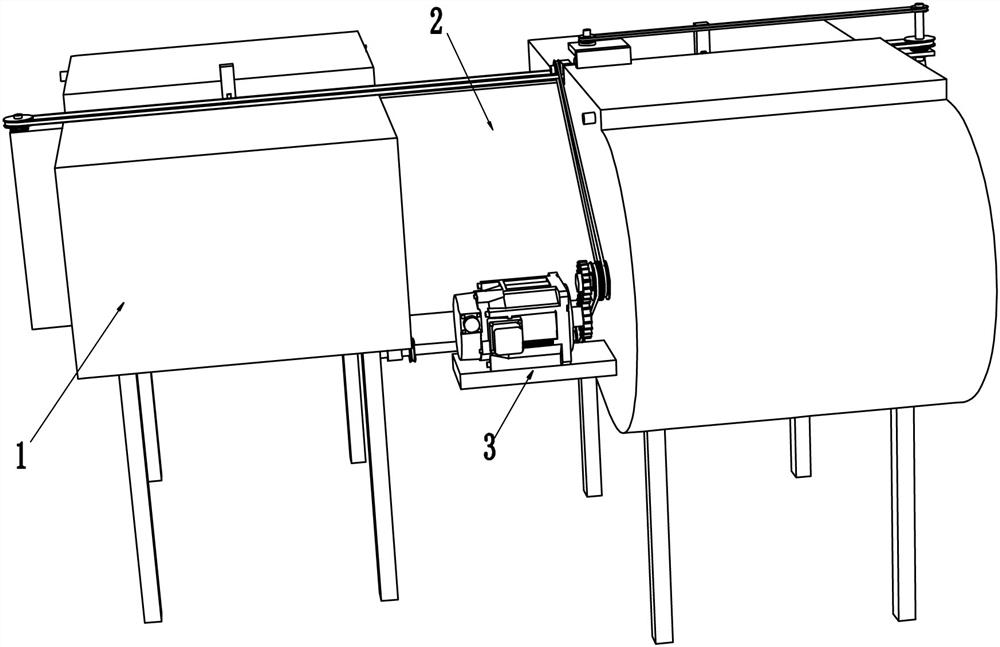

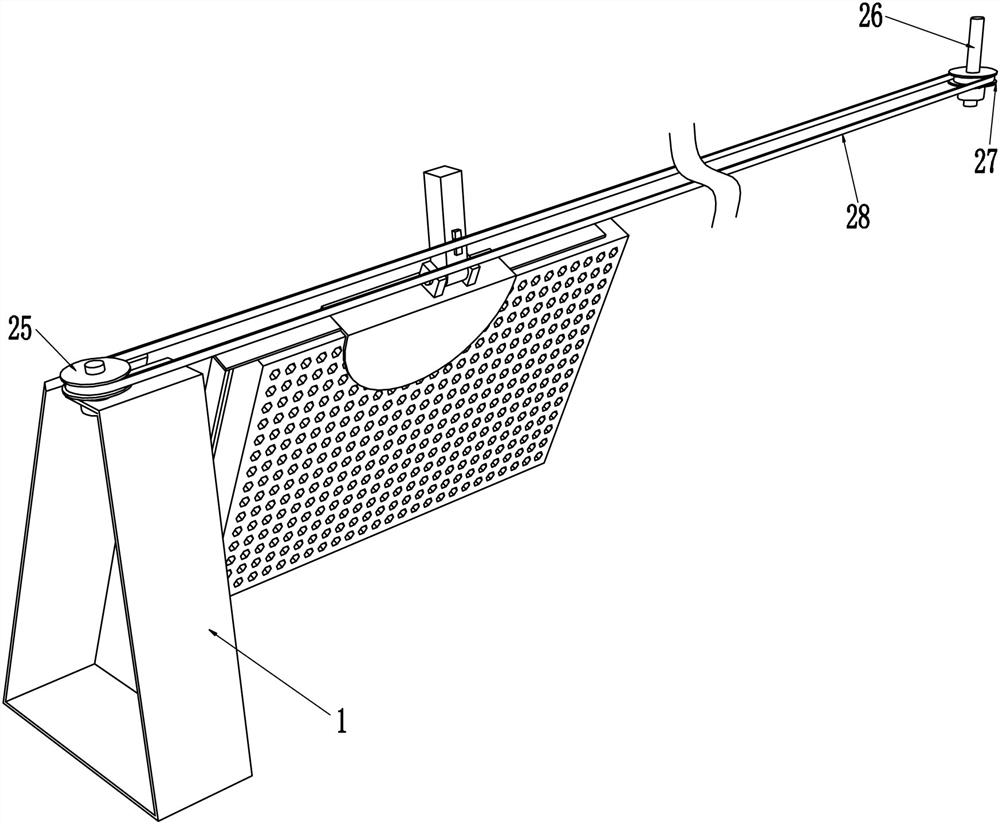

[0026] A double-sided honeycomb flouring machine, refer to figure 1 , figure 2 , image 3 , Figure 7 and Figure 8 , including the applicator box 1, the transition box 2, the support block 3, the applicator assembly, the support rod 16, the guide rod 17, the drive assembly, the moving assembly and the isolation sleeve 34, the left and right sides of the transition box 2 are fixed with the applicator box 1, A support block 3 is provided on the lower left side of the right applicator box 1, and both the left and right applicator boxes 1 are provided with applicator components. The applicator components are used to apply pollen to the honeycomb panel 35. The assembly is used to drive the applicator assembly, and the drive assembly is connected to the applicator assembly. The left and right applicator boxes 1 are provided with moving assemblies. The moving assemblies are used to move the honeycomb panel 35. The top of the left and right applicator boxes 1 and the transition b...

Embodiment 2

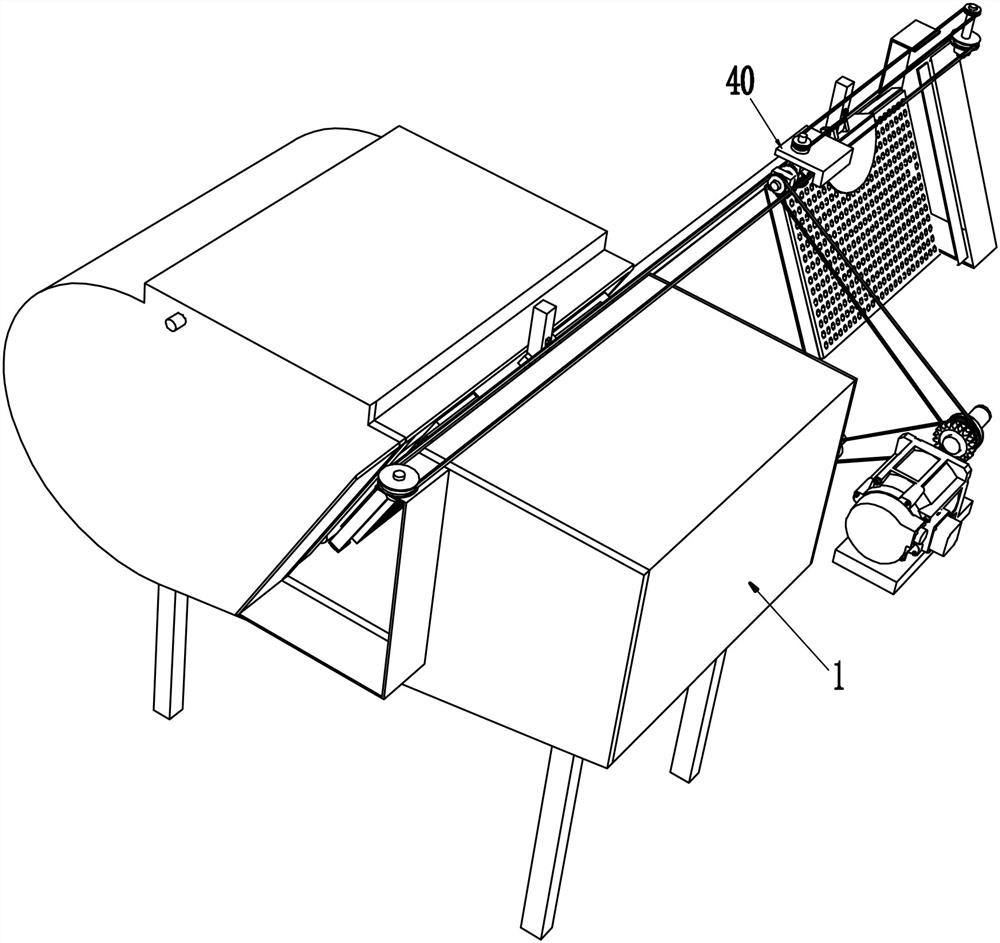

[0035] On the basis of Example 1, refer to Figure 9 , also includes a second connecting rod 36, a sixth transmission wheel 37, a fifth belt 38, a first bevel gear 39, a mounting block 40, a third connecting rod 41, a second bevel gear 42, and a seventh transmission wheel 43 and the sixth belt 44, the upper part of the left wall of the applicator box 1 on the right side is rotatably installed with a second connecting rod 36, one end of the second connecting rod 36 is provided with a sixth transmission wheel 37, and the fifth belt 38 is wound around the double-groove transmission wheel. 6 and the sixth transmission wheel 37, the other end of the second connecting rod 36 is provided with a first bevel gear 39, the top of the applicator box 1 on the right is provided with a mounting block 40, and the middle of the mounting block 40 is rotatably connected with a third connection Rod 41, the lower part of the third connecting rod 41 is provided with a second bevel gear 42, the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com