Textile size storage device convenient to use

A storage device and slurry technology, applied in transportation and packaging, mixers with rotating containers, dissolution, etc., can solve problems affecting users' normal use of slurry, slurry condensation, and lack of stirring structures in storage tanks, etc., to achieve Rich in functions, improved slurry quality, and easy to clean up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

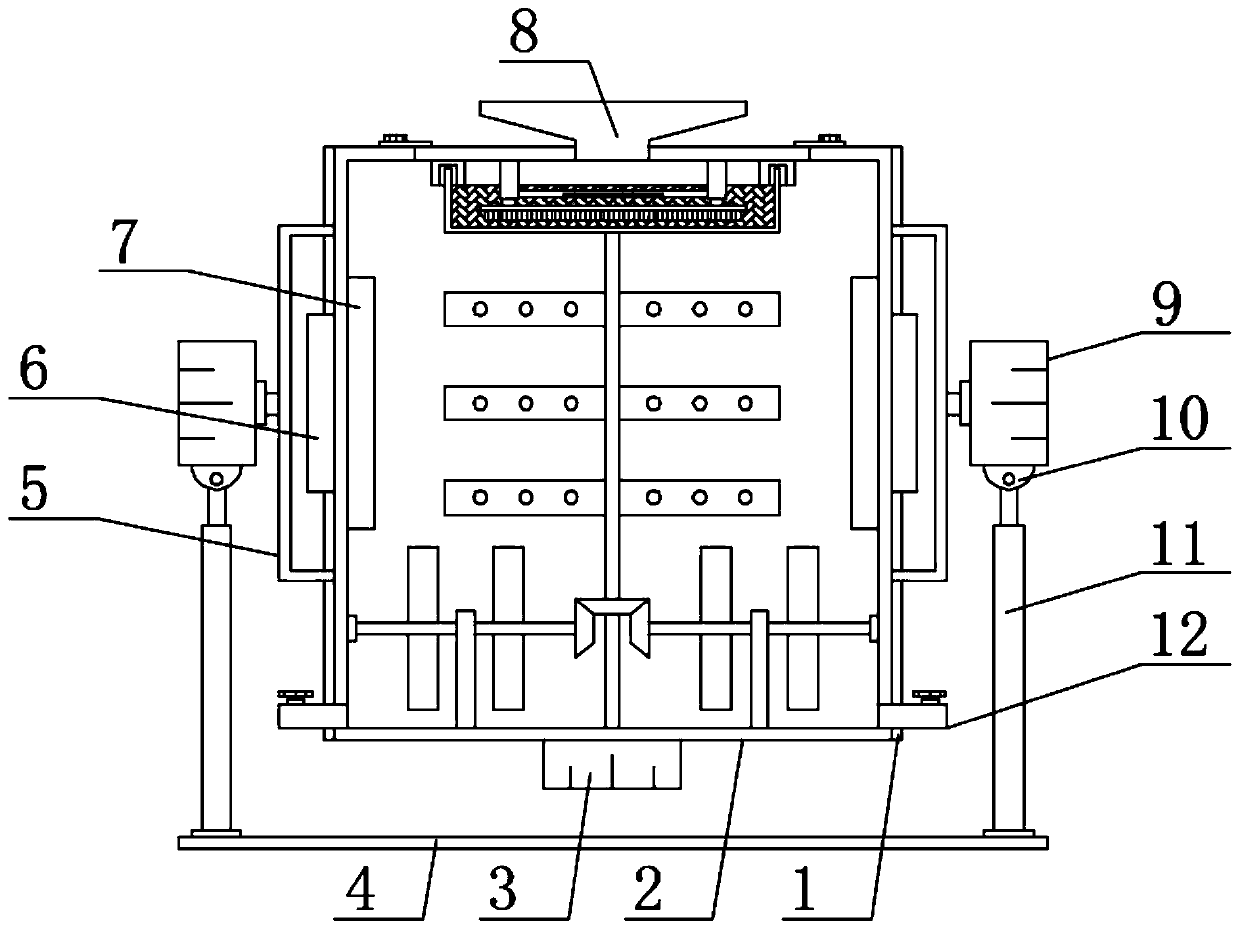

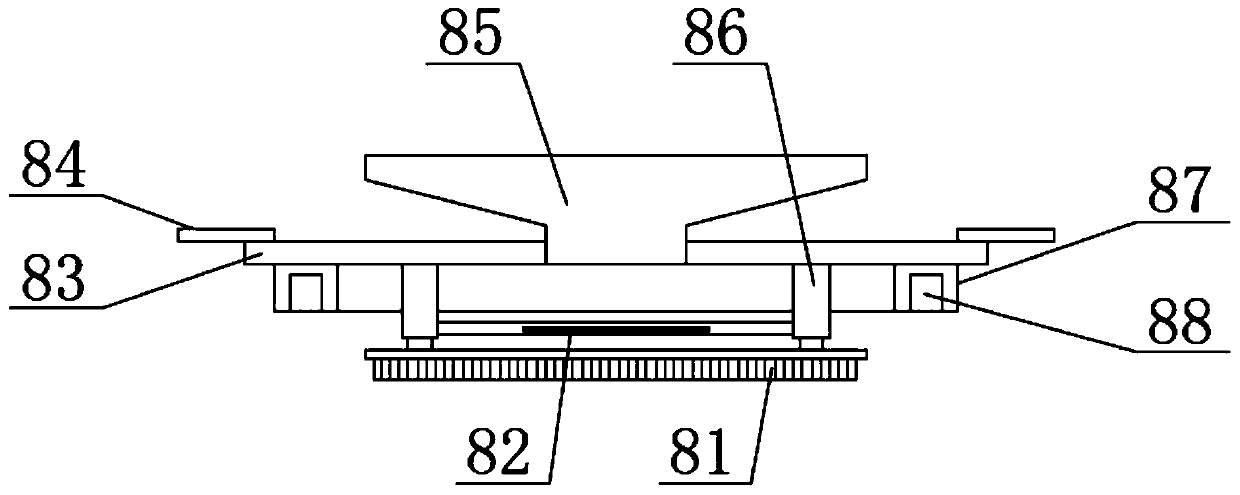

[0024] see Figure 1-Figure 4 , the present invention provides a technical solution: an easy-to-use textile slurry storage device, comprising a storage tank 2, the two sides of the storage tank 2 are welded with discharge pipes 12, and the two sides of the storage tank 2 are also provided with Microwave heater 6 is arranged, and the use of microwave heater 6 is prior art, and the top of storage tank 2 is provided with unloading mechanism 8, and unloading mechanism 8 comprises support top plate 83, and the upper surface middle part of support top plate 83 is provided with unloading hopper 85, the two ends of the support top plate 83 are welded with a fixed plate 84 corresponding to the storage tank 2, and one end of the fixed plate 84 is fixedly connected with the storage tank 2 by screws;

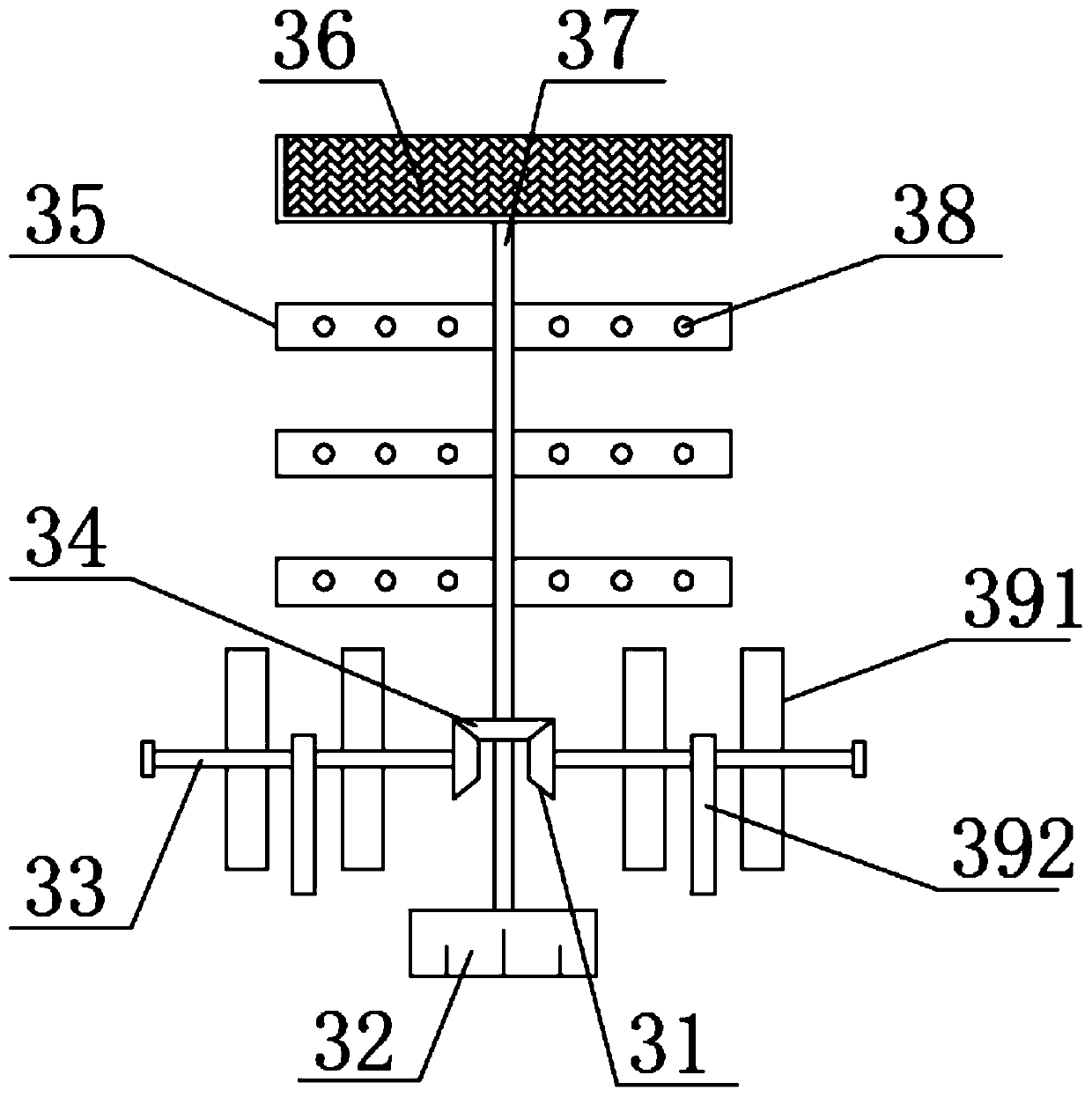

[0025] The bottom end of the storage tank 2 is provided with a stirring mechanism 3, the stirring mechanism 3 includes a second drive motor 32, the output end of the second drive motor 32 i...

Embodiment 2

[0031] On the basis of Embodiment 1, in order to make the use of the filter screen cover 36 more reliable, in this embodiment, preferably, the lower surface of the supporting top plate 83 is provided with a limit slide rail 87, and the bottom end of the limit slide rail 87 is provided with a The limit chute 88 corresponding to the filter screen cover 36 is used to limit the filter screen cover 36 by the limit slide rail 87;

[0032] In order to make the use of the limit slide rail 87 more reliable, in this embodiment, preferably, the top of the limit slide rail 87 is fixedly connected to the support top plate 83 by welding, and the bottom end of the electric telescopic rod 86 is provided with a heating plate 82, The heating plate 82 is a cuboid structure;

[0033] In order to make the use of the heating plate 82 more reliable, in this embodiment, preferably, the two ends of the heating plate 82 are fixedly connected with the electric telescopic rod 86 by welding, and the insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com