A low-noise axial flow fan

An axial flow fan and low-noise technology, which is applied in the direction of axial flow pumps, mechanical equipment, machines/engines, etc., can solve the problems of high noise in use and no noise reduction design, etc., and achieve the effect of low noise in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

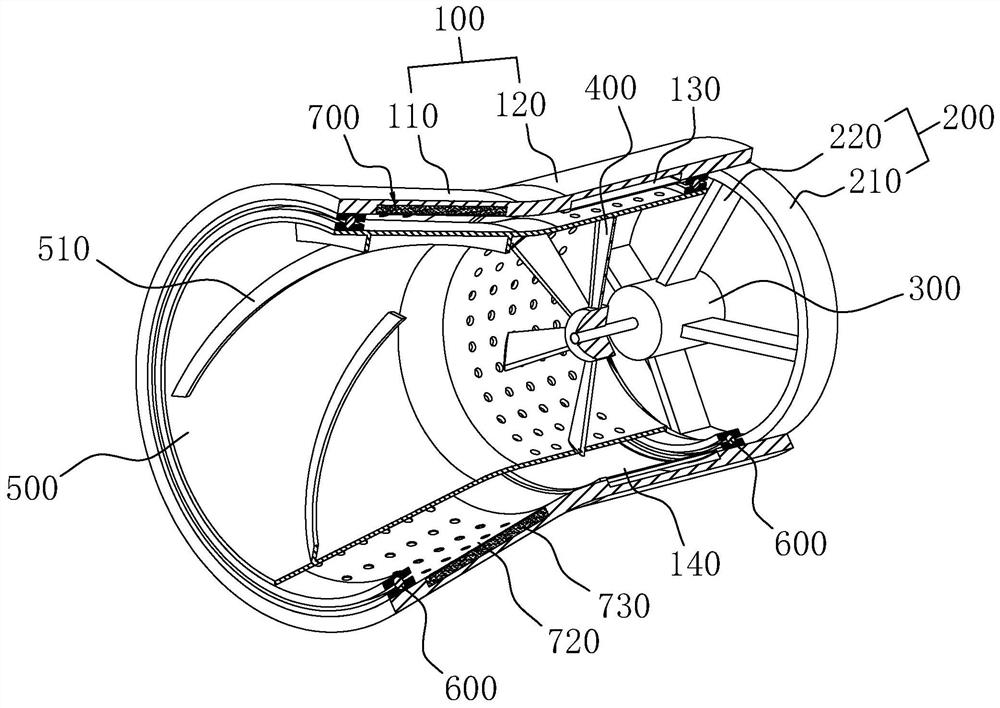

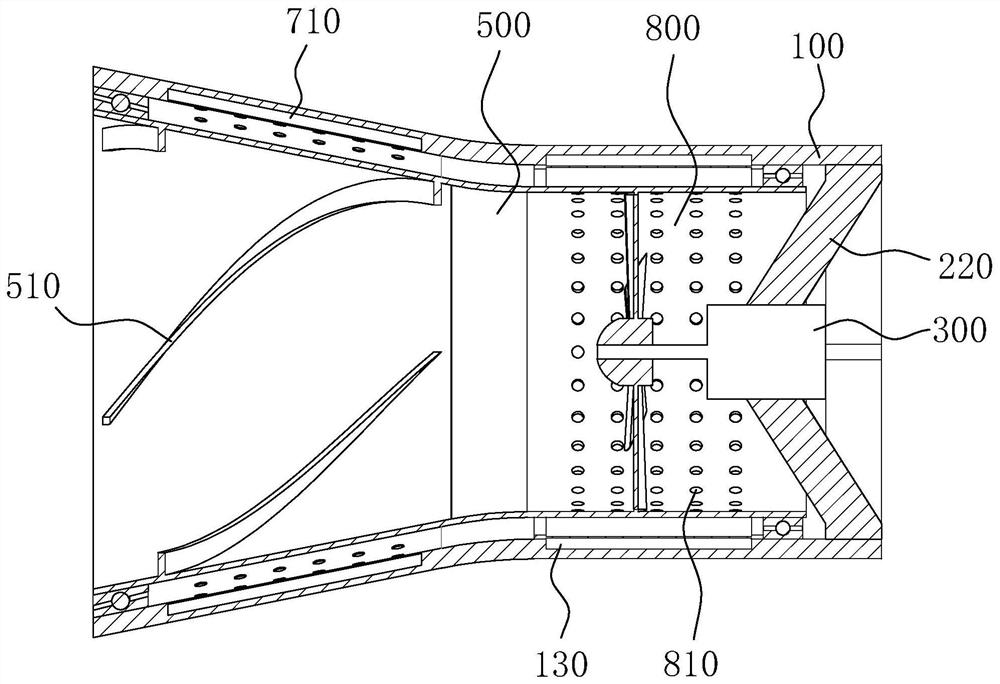

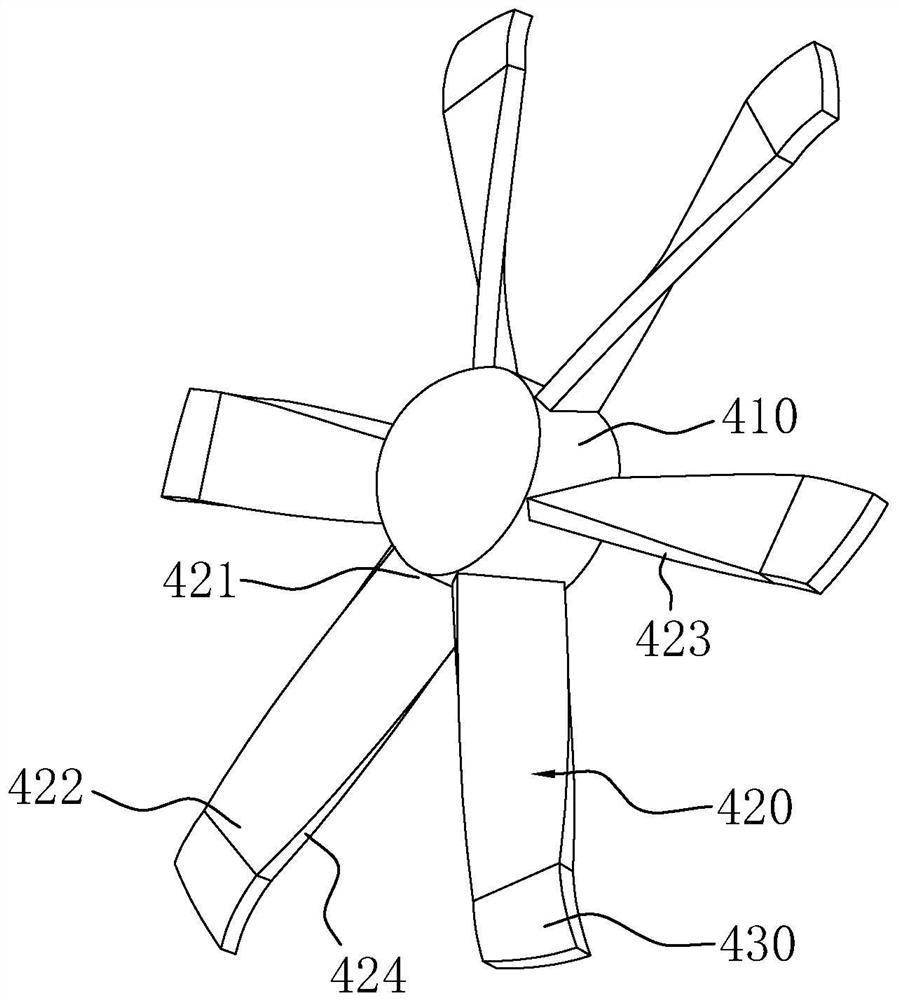

[0036] A low-noise axial flow fan, such as figure 1 As shown, it includes a housing 100, a fixed frame 200, a driving motor 300, a wind wheel 400 and a rotating cylinder 500. The housing 100 is in a cylindrical structure, and it is divided into a straight cylinder part 120 and an expanded cylinder part 110 along the axial direction. The straight cylinder part 120 and the expanded tube part 110 are integrally arranged, wherein the opening at the end of the expanded tube part 110 with a larger diameter is used as an air outlet, and the opening of the straight tube part 120 is used as an air inlet.

[0037] The fixing frame 200 includes a fixing ring 210 and a connecting arm 220 , and the fixing ring 210 is fixed and installed at the air inlet of the straight barrel portion 120 by bolts. There are four connecting arms 220 . combined with figure 2 One end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com