Multi-stage drying equipment for grain quality guarantee

A technology for drying equipment and grain, which is applied in the directions of grain drying, drying solid materials, drying gas arrangement, etc., can solve the problems of uneven grain drying, inconvenient drying, slow drying speed, etc. The effect of convenient material and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

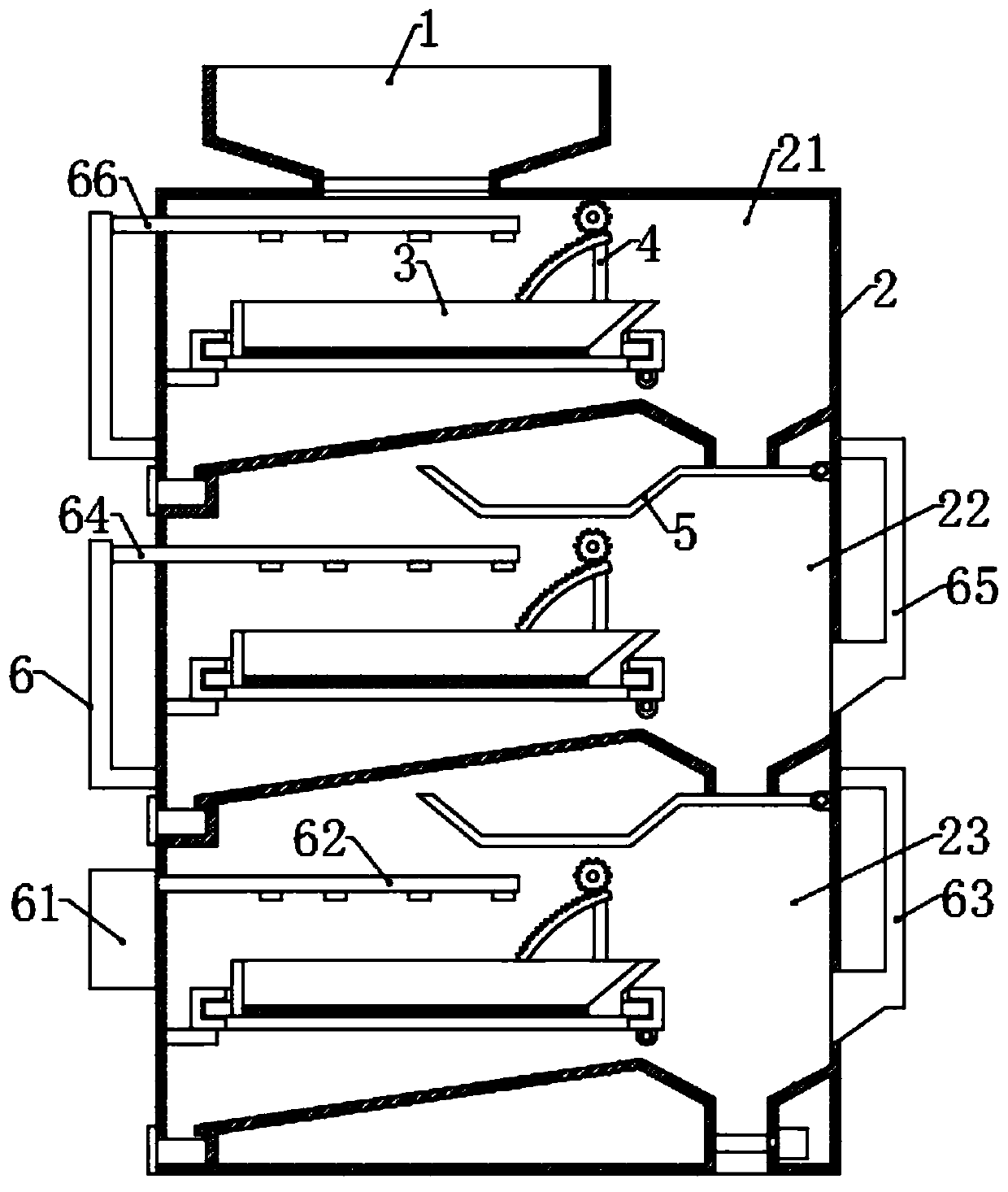

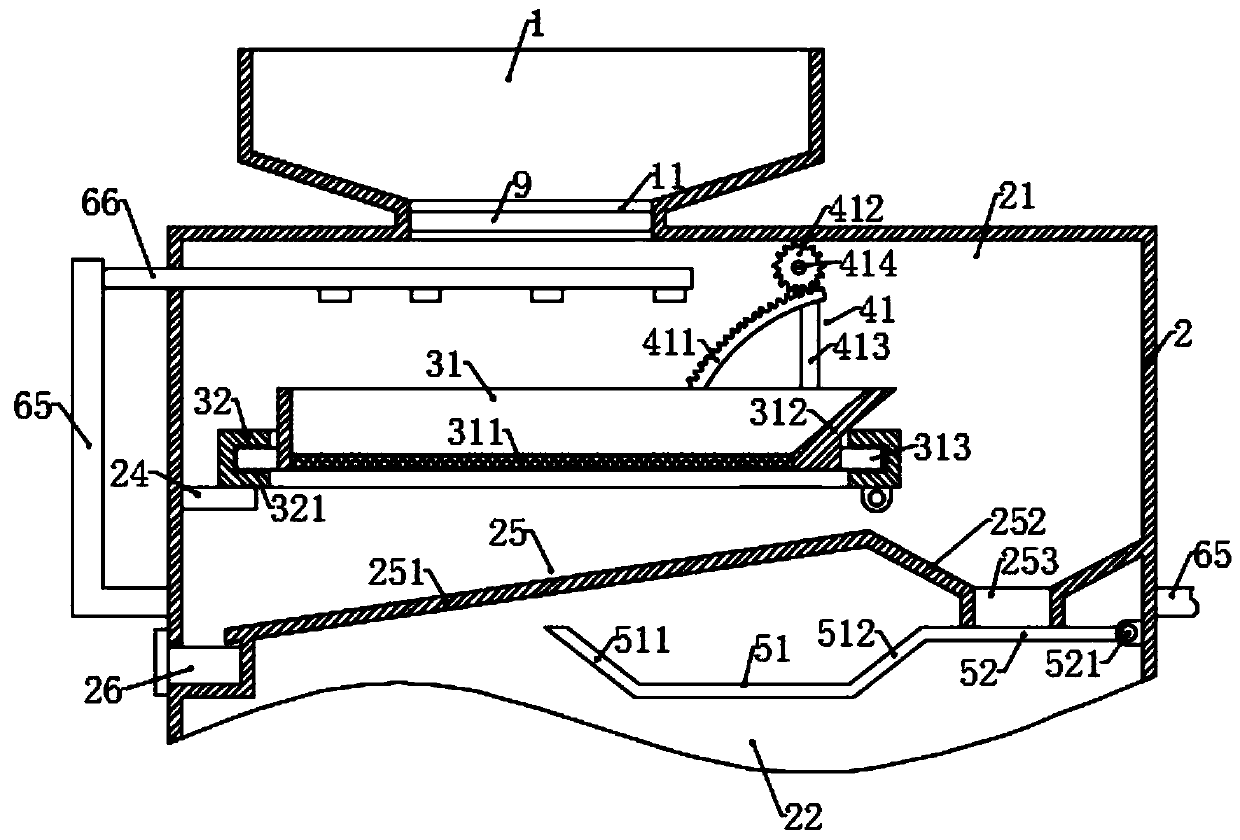

[0037] Please refer to the accompanying drawings, the present invention provides a technical solution: a multi-stage drying equipment for food quality preservation, including a feed hopper 1 and a drying box 2, the bottom surface of the feed hopper 1 and the drying box 2 The top surface is communicated through the feeding pipe 11, and the feeding assembly 9 is arranged in the feeding pipe 11, and the first drying chamber 21, the second drying chamber 22 and the first drying chamber 22 are arranged in the drying box 2 from top to bottom. Three drying chambers 23, the middle part of the first drying chamber 21, the second drying chamber 22 and the third drying chamber 23 are all provided with the vibration mechanism 3 of the same structure, the bottom is fixed with a bottom plate 25, and the bottom plate 25 is provided with a blanking Mouth 253, the baffle plate 5 that corresponds to the discharge port 253 on the side wall of the drying box 2 is rotated and connected, and the fir...

Embodiment 2

[0045] On the basis of Embodiment 1, the feeding assembly includes a material guide platform 93 fixed in the middle of the feeding tube 11, the top surface of the material guide platform 93 is inclined to both sides, and two symmetrically arranged below the material guide platform 93 A rotating plate 91, the inner end of the rotating plate 91 is located below the material guide table 93, and the short shaft 92 is fixed on both sides, and is connected to the side wall of the feeding pipe 11 through the short shaft 92 in rotation, wherein, on the same side, The two short shafts 92 are respectively fixedly connected with a blanking gear, and the two blanking gears mesh with each other, and one of the short shafts 92 is also connected with a blanking motor.

[0046] When needing to carry out blanking, the blanking motor drives the rotating plate 91 to rotate through two blanking gears, opens the blanking pipe 11, and grain enters in the first drying chamber 21 by the material guide...

Embodiment 3

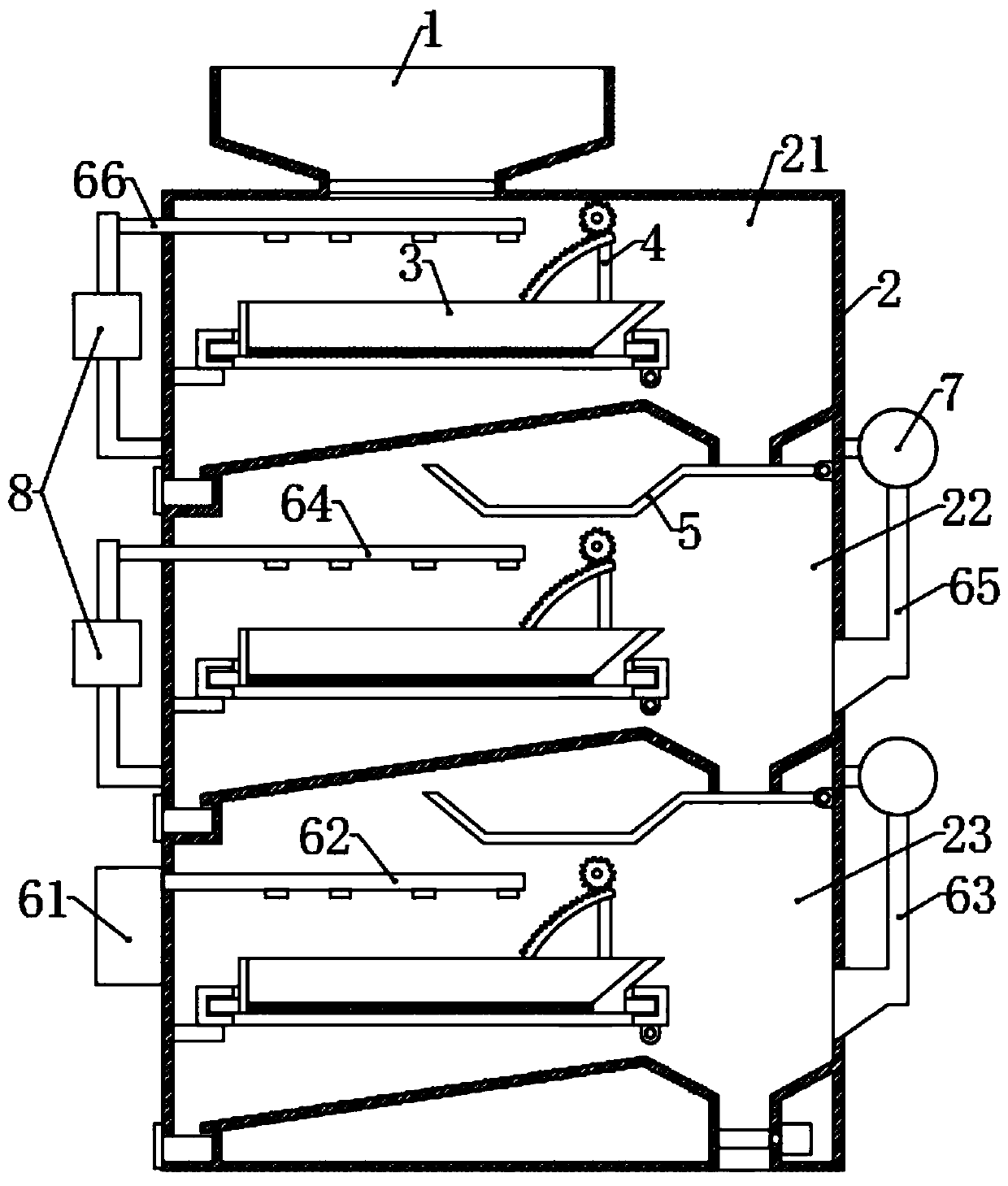

[0048] On the basis of the second embodiment, the first recovery pipe 65 and the second recovery pipe 63 are arranged along the outside of the drying box 2, both of which include a right-angle pipe, and a drying mechanism 7 is arranged at the corner of the right-angle pipe. The drying mechanism 7 includes a circular drying box 71, the center of the drying box 71 is rotatably connected with a rotating shaft 72, and the rotating shaft 72 is provided with three drying plates 74 and a sealing plate 73 along the circumference, and the interval angles are equal. The drying plate 74 comprises a fixed frame 741 fixed on the rotating shaft 72, and both sides of the fixed frame 741 are provided with a ventilation plate 742, the ventilation plate 742 and the fixed frame 741 form a cavity, and a filler 743 for drying is arranged in the cavity. .

[0049] When the grain is dried by hot air, water vapor will be generated, which will cause the humidity in the drying box 2 to increase. Theref...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap