Diagnosis system for enhancing nitrogen sealing performance of PDH special valve

A technology of nitrogen sealing and diagnosis system, which is applied in fluid tightness testing, liquid tightness measurement using liquid/vacuum degree, and measurement of fluid growth and deceleration rates, etc. It can solve collection breakpoints, incomplete records, large valves, etc. The running state is not stable enough, the basis for judgment is insufficient, etc., to avoid incomplete information collection and recording, convenient and fast running state, and realize the effect of data recording

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below.

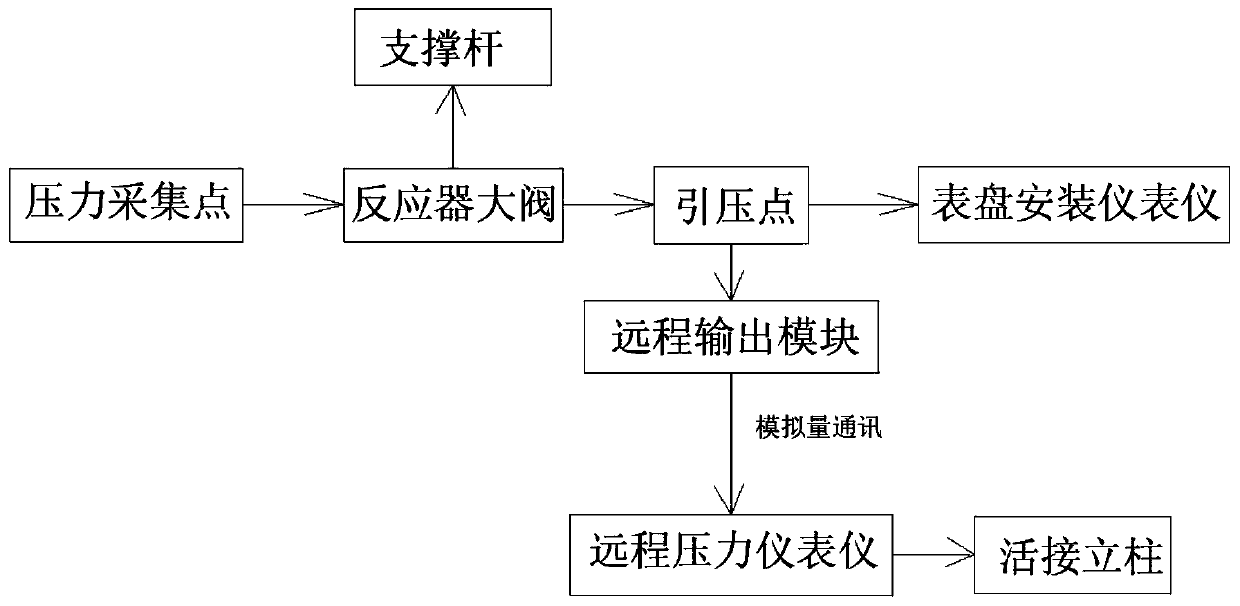

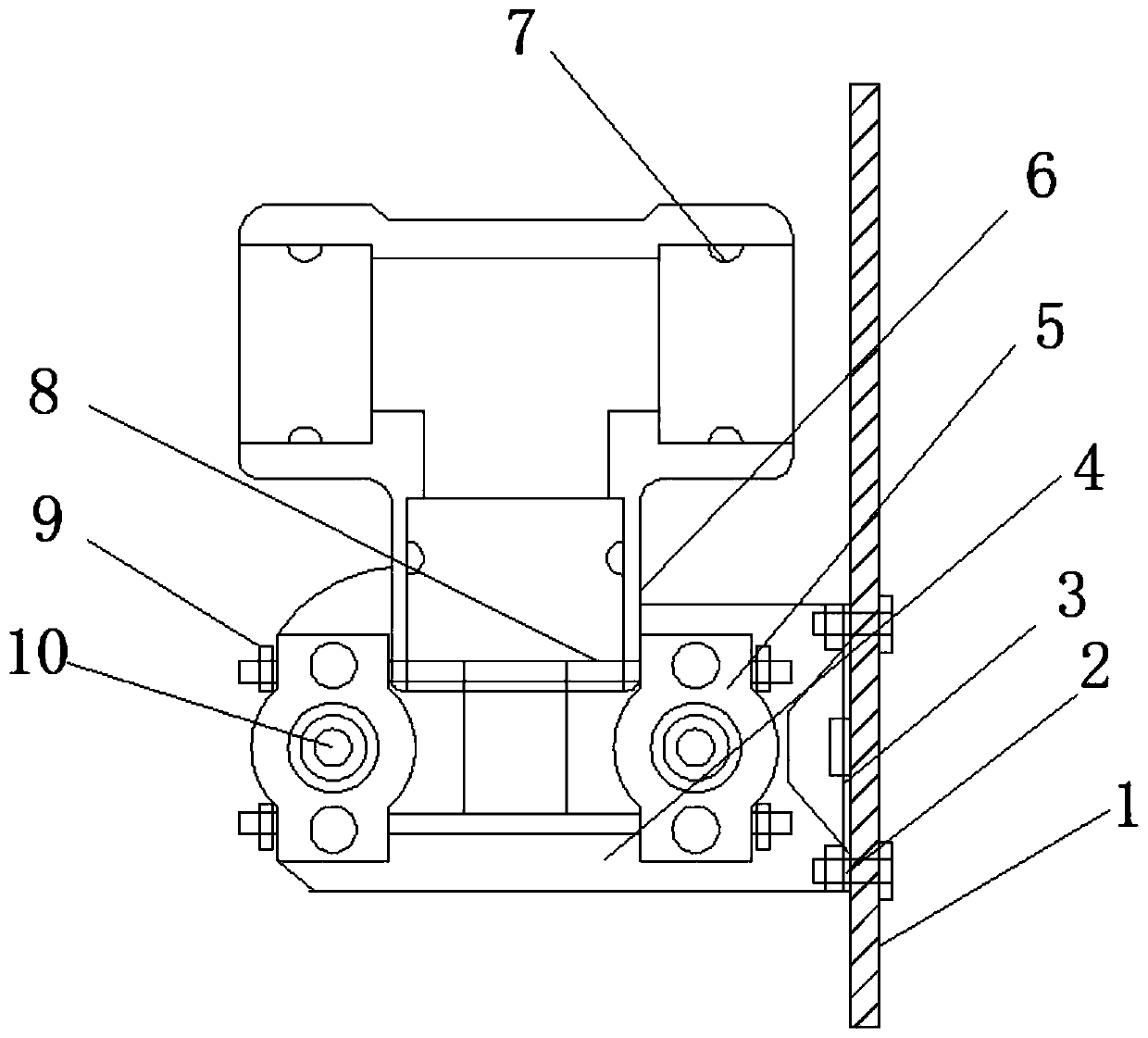

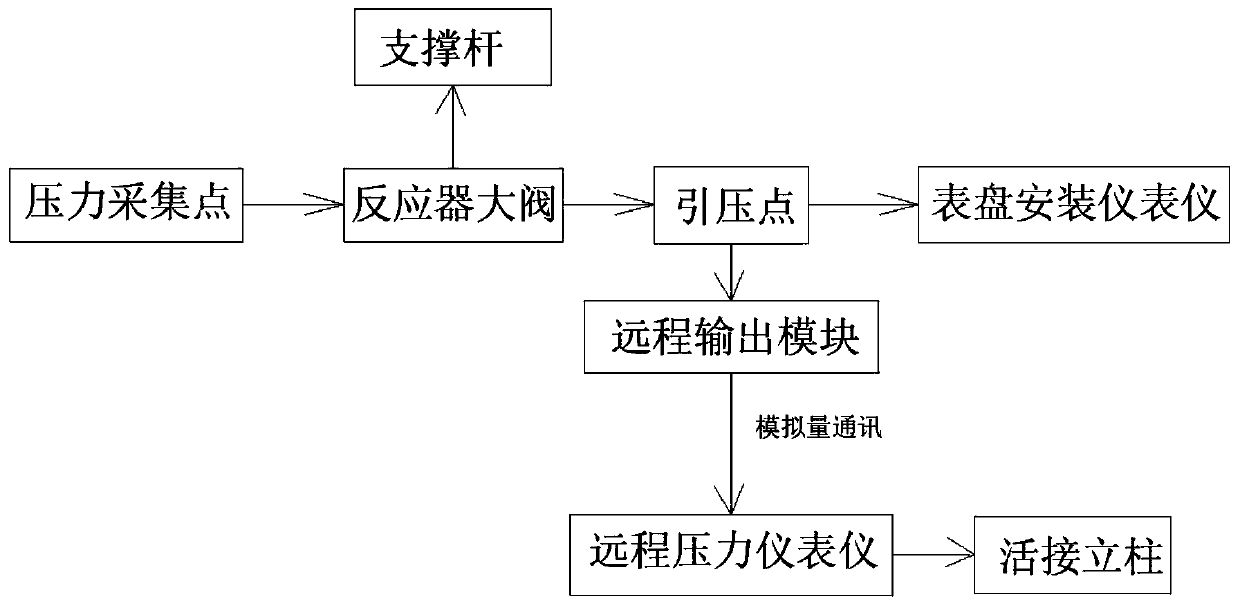

[0020] Please refer to figure 1 , figure 2 , a PDH special valve increased nitrogen sealing performance diagnostic system, including a large reactor valve 6 and a joint column 1, characterized in that: the large reaction valve 6 is set to multiple groups, and the multiple groups of large reactor valves 6 are respectively fixed Set on different joint columns 1, the reactor large valve 6 is combined with the pressure collection point and the dial-mounted instrument to form a leak-tightness diagnosis system for increasing the nitrogen sealing performance, and the output end of the pressure collection point It is connected to the collection input point of the large reactor valve 6 through a contact method, the output end of the large reactor valve 6 is connected to the input end of the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com