Intelligent storage and delivery method integrating AGV and mechanical arm

A technology of intelligent warehousing and robotic arms, applied in the direction of electric/hybrid power, comprehensive factory control, program control, etc., can solve problems such as efficiency bottlenecks, reduce personnel costs, improve delivery accuracy and real-time performance, and improve delivery efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

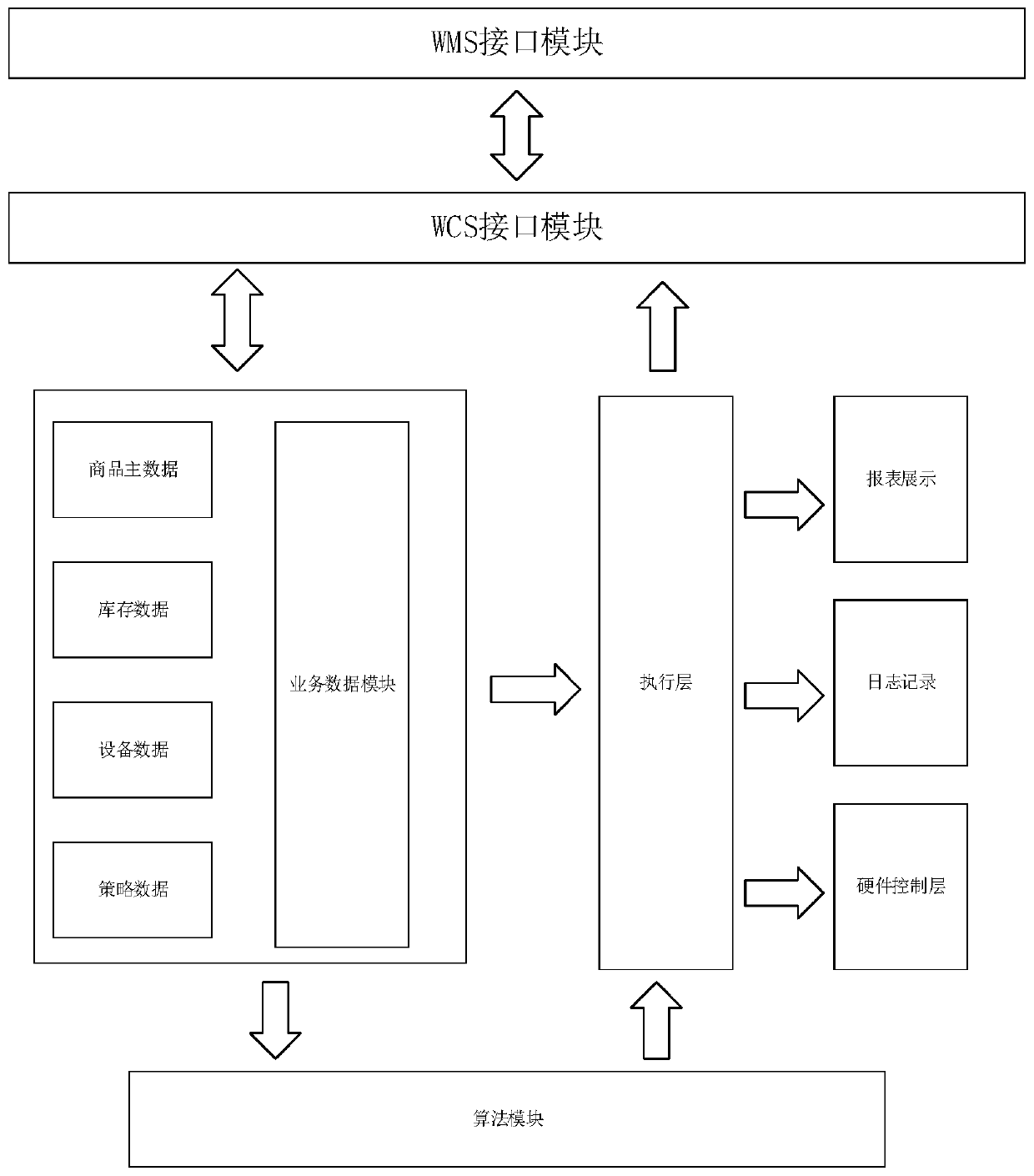

[0134] (1) Data preparation

[0135] (1) Map design

[0136] AGV, robotic arm map design, including placement of robotic arm, AGV area division, AGV operating route, where AGV area division includes transportation area and storage area.

[0137] (2) On-site master data collection and initialization

[0138] On-site master data includes map master data, shelf master data, robotic arm-related master data, cargo location master data, and container master data.

[0139] (3) commodity master data initialization

[0140] Receive commodity master data information from WMS through the interface module, including commodity length, width, height, barcode information and commodity description.

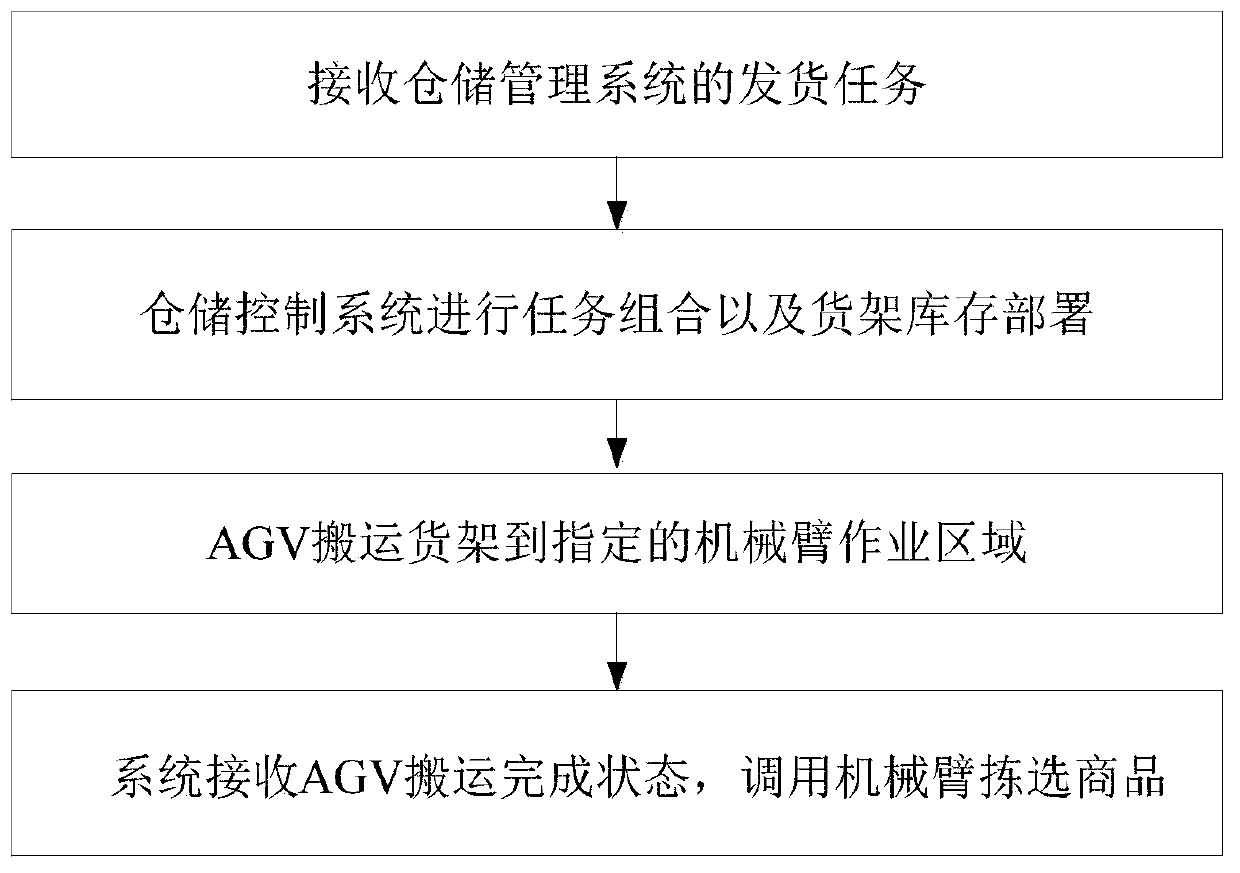

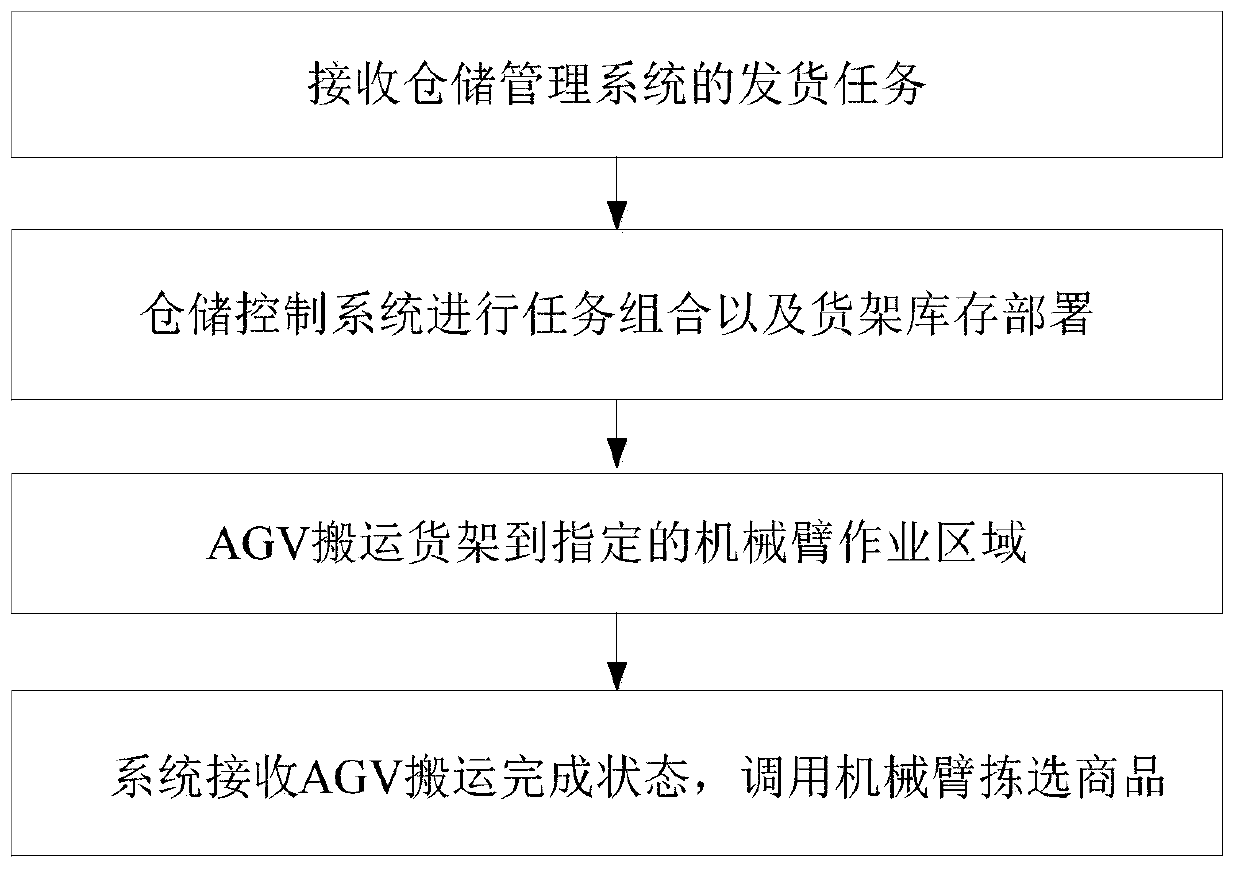

[0141] (2) Task execution

[0142] (1) Task reception

[0143] Receive WMS delivery task data through the interface module, including task order number and delivery details.

[0144] (2) Algorithm module selection task and shelf deployment

[0145] Calculate the optimal task combination fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com