Electric shock pest killing device for automatic crop pest monitoring and reporting system

An insecticidal device and a technology for crops, which are applied in the device, application, animal husbandry and other directions of capturing or killing insects, can solve the problems of high power consumption, high cost, complex structure, etc., reduce the overlap rate and save energy. , the effect of easy identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

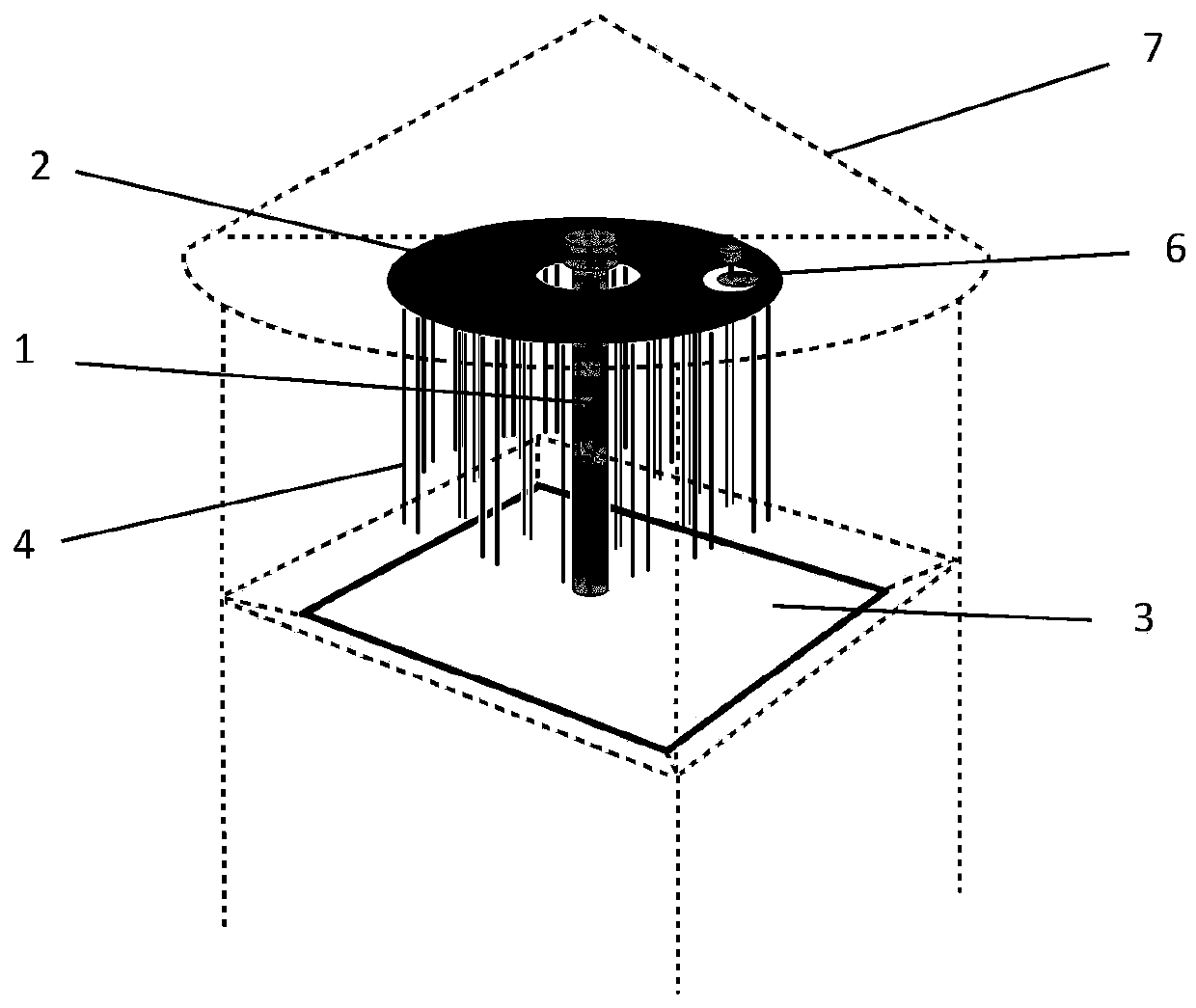

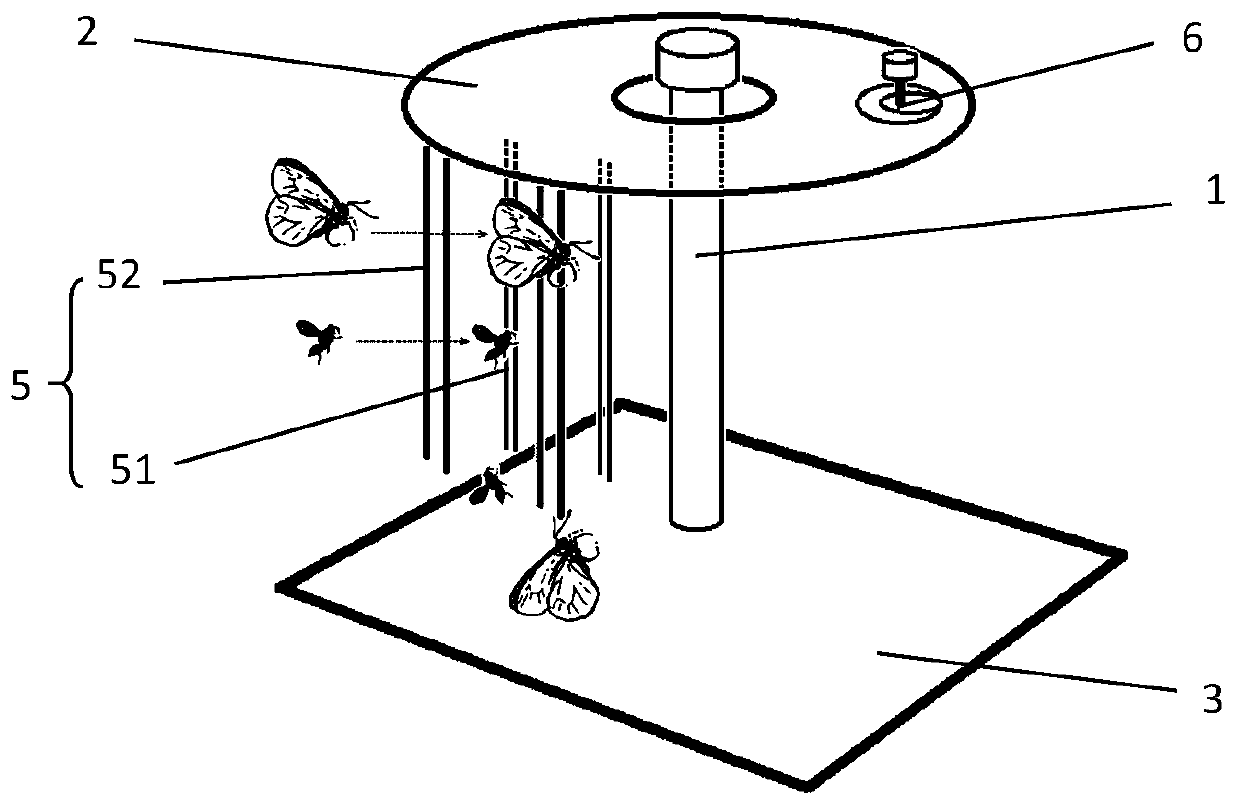

[0061] See attached Figure 1-4 , this embodiment discloses an electric shock killing device for an automatic pest detection and reporting system for crops, including an insect trap lamp 1, an insulating platform 2, an insect receiving platform 3, and an inner and outer two-layer electric pole arranged in sequence on the periphery of the insect trap lamp. The pole group 5, wherein the inner pole group 5 is composed of a plurality of first pole groups 51, the outer pole group 5 is composed of a plurality of second pole groups 52, and the insulating platform 2 is equipped with an eccentric shaft motor 6, wherein each Each pole group 5 is made up of two DC poles 4 each being a positive pole and a negative pole.

[0062] The insect trap lamp 1 passes through the insulating platform 2 and is fixed on the rainproof cover 7 on the top of the forecasting system, and each DC pole 4 is vertically fixed on the insulating platform 2, and there is a gap between the bottom of the DC pole 4 ...

Embodiment 2

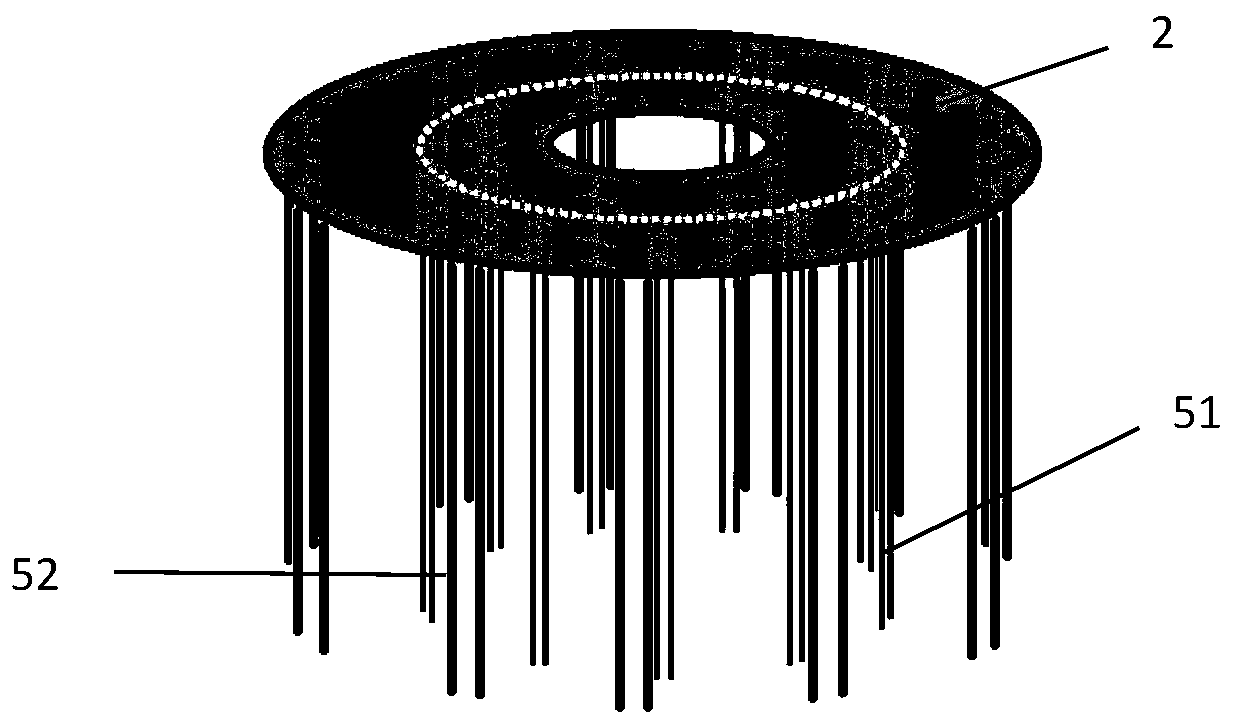

[0065] See attached Figure 5 , this embodiment discloses an electric shock insecticidal device used in an automatic pest detection and reporting system for crops, including an insect trap lamp 1, an insulating platform 2, an insect receiving platform 3, and three-layer electric poles arranged in sequence on the periphery of the insect trap lamp Group 5, wherein the inner pole group 5 is composed of a plurality of first pole groups 51, the outer pole group 5 is composed of a plurality of second pole groups 52, and the middle pole group 5 is composed of first An electric pole group 51 and a second electric pole group 52 are formed. The insulating platform 2 is equipped with an eccentric shaft motor 6, wherein each electric pole group 5 is composed of two DC electric poles 4 each being a positive pole and a negative pole.

[0066] The insect trap lamp 1 passes through the insulating platform 2 and is fixed on the rainproof cover 7 on the top of the forecasting system, and each D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com