Automatic feeding bamboo shoot peeling machine for phyllostachys praecox shoots

A technology of automatic feeding and bamboo shoots, which is applied in applications, peeling of vegetables or fruits, food processing, etc., can solve the problems of heavy workload and low efficiency of manual peeling, and achieve improved peeling efficiency, reduced workload, and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

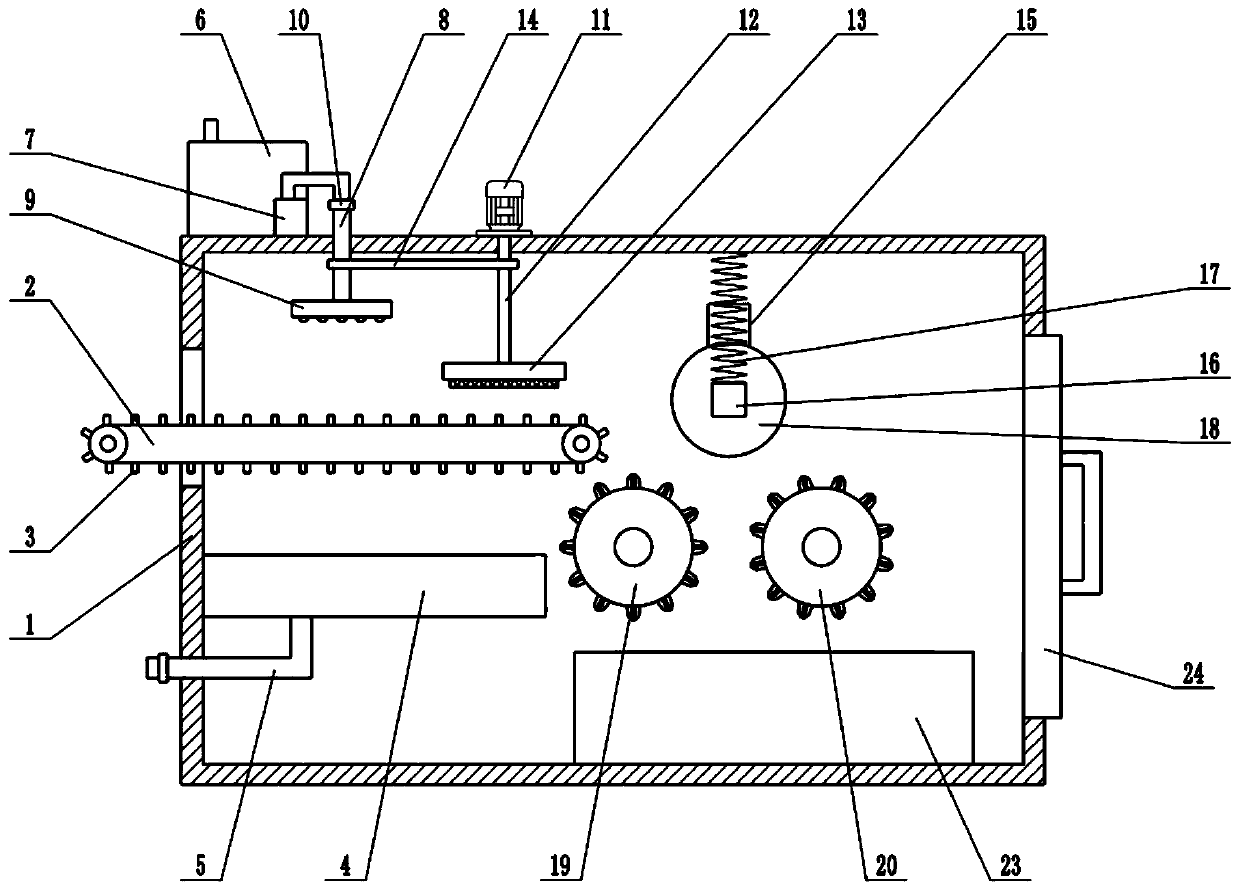

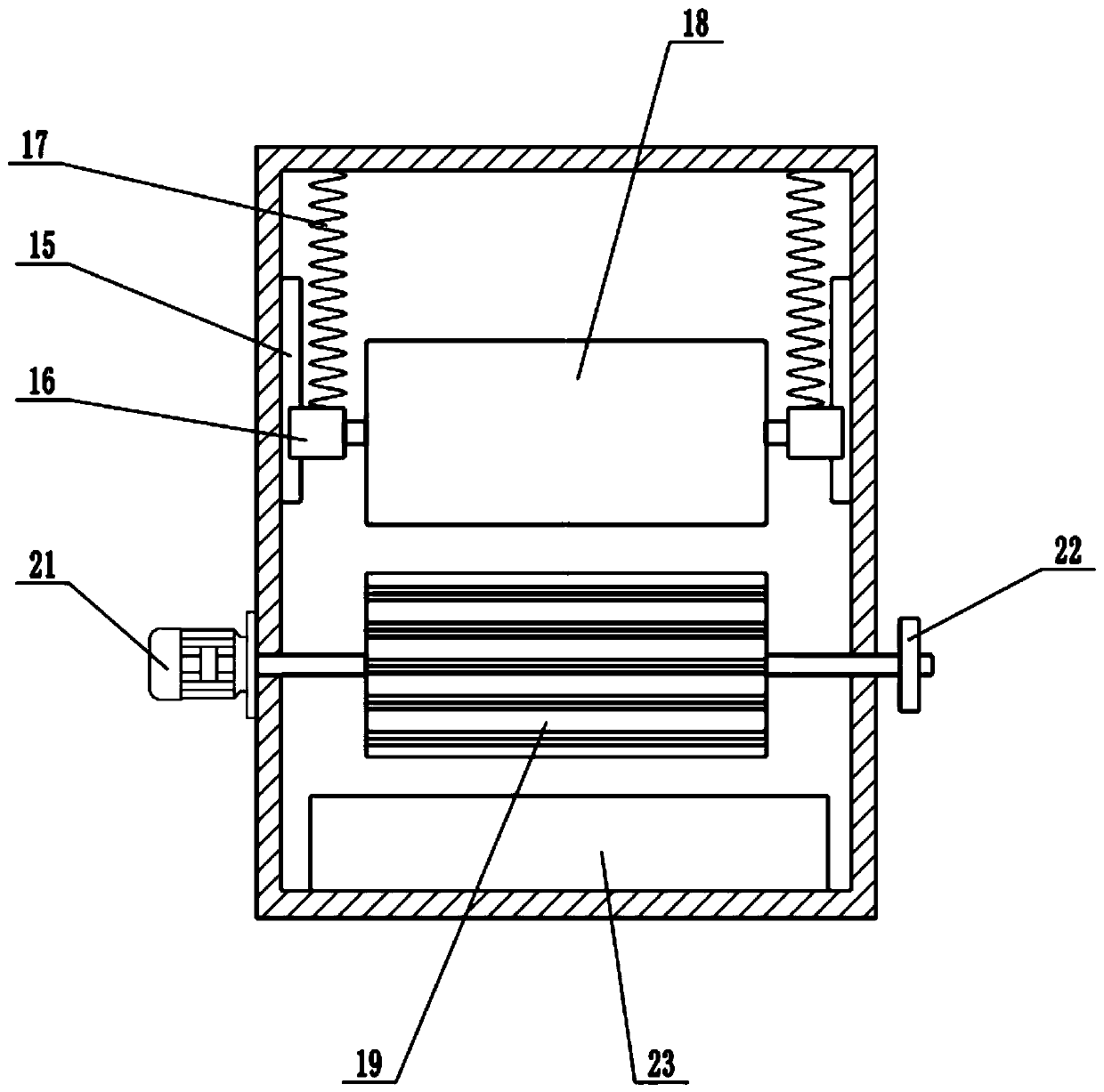

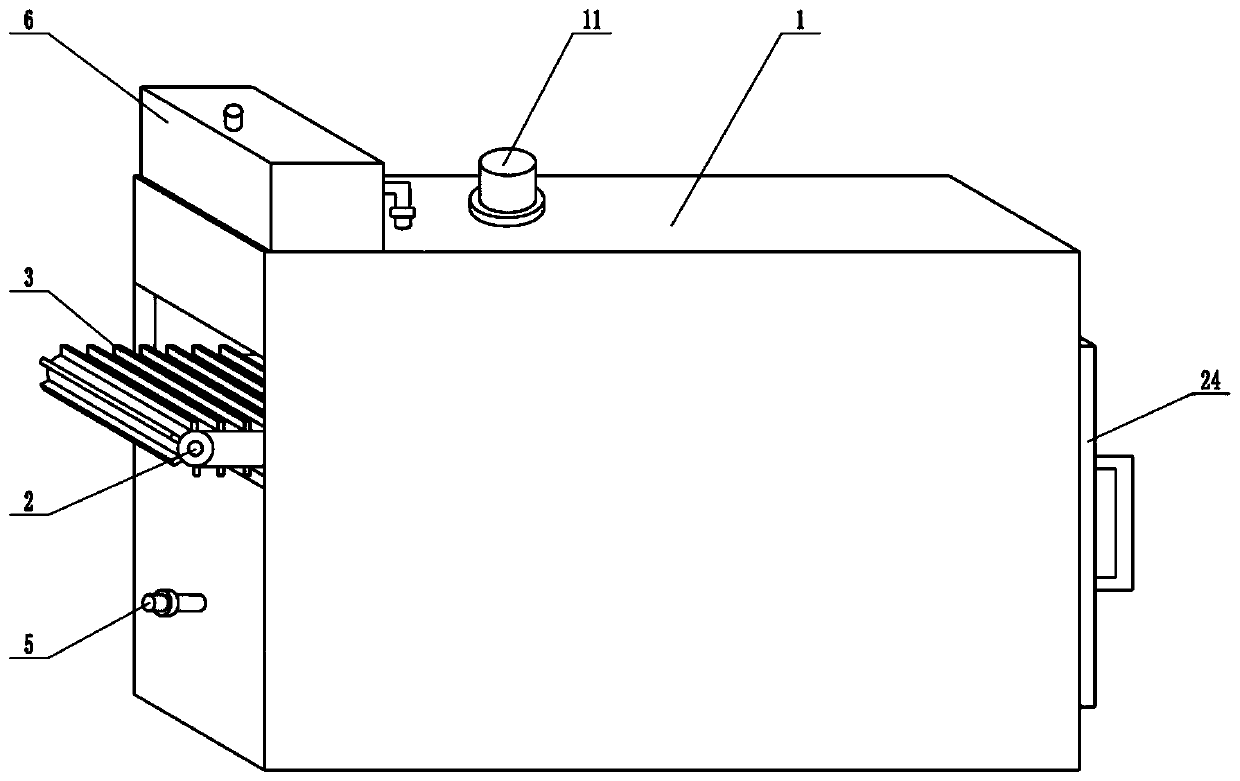

[0023] see Figure 1-3 , in the embodiment of the present invention, a kind of automatic feeding and peeling machine for thunder bamboo shoots comprises shell 1, conveyer belt 2, active peeling roller 19 and driven peeling roller 20, and the inside of shell 1 is equipped with conveyer belt 2, and the inside of shell 1 The side wall is provided with a rectangular hole, and the left end of the conveyor belt 2 protrudes from the rectangular hole. The surface of the conveyor belt 2 is equidistantly distributed with non-slip convex ribs 3. Put the bamboo shoots to be peeled on the conveyor belt 2, and use the conveyor belt 2 to transport the bamboo shoots to Inside the shell 1, there are through holes distributed on the upper surface of the conveyor belt 2. A hollow shaft 8 is installed on the top of the shell 1. The lower end of the hollow shaft 8 extends into the shell 1. The hollow shaft 8 is rotationally connected with the shell 1. The hollow shaft 8 The lower end is equipped w...

Embodiment 2

[0025] On the basis of Embodiment 1, the top of the casing 1 is fixedly connected with the first motor 11, and the shaft extension end of the first motor 11 is fixedly connected with the driving shaft 12, and the driving shaft 12 extends into the casing 1, and the driving shaft 12 passes through the transmission belt 14 Connected with the hollow rotating shaft 8, the lower end of the driving shaft 12 is equipped with a brush plate 13, the lower surface of the brush plate 13 is distributed with bristles, the first motor 11 is started to drive the driving shaft 12 to rotate, thereby driving the brush plate 13 to rotate, and the brush plate 13 is used to rotate. 13 scrub the surface of thunder bamboo shoots, while driving shaft 12 rotates, drive hollow rotating shaft 8 to rotate by transmission belt 14, thereby drive spraying disc 9 to rotate, make spraying process more even.

[0026] In conjunction with Embodiment 1 and Embodiment 2, the working principle of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com