Liquid separation device

A technology of liquid separation device and liquid distribution device, which is applied in the direction of centrifuge, etc., to achieve the effect of simple operation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

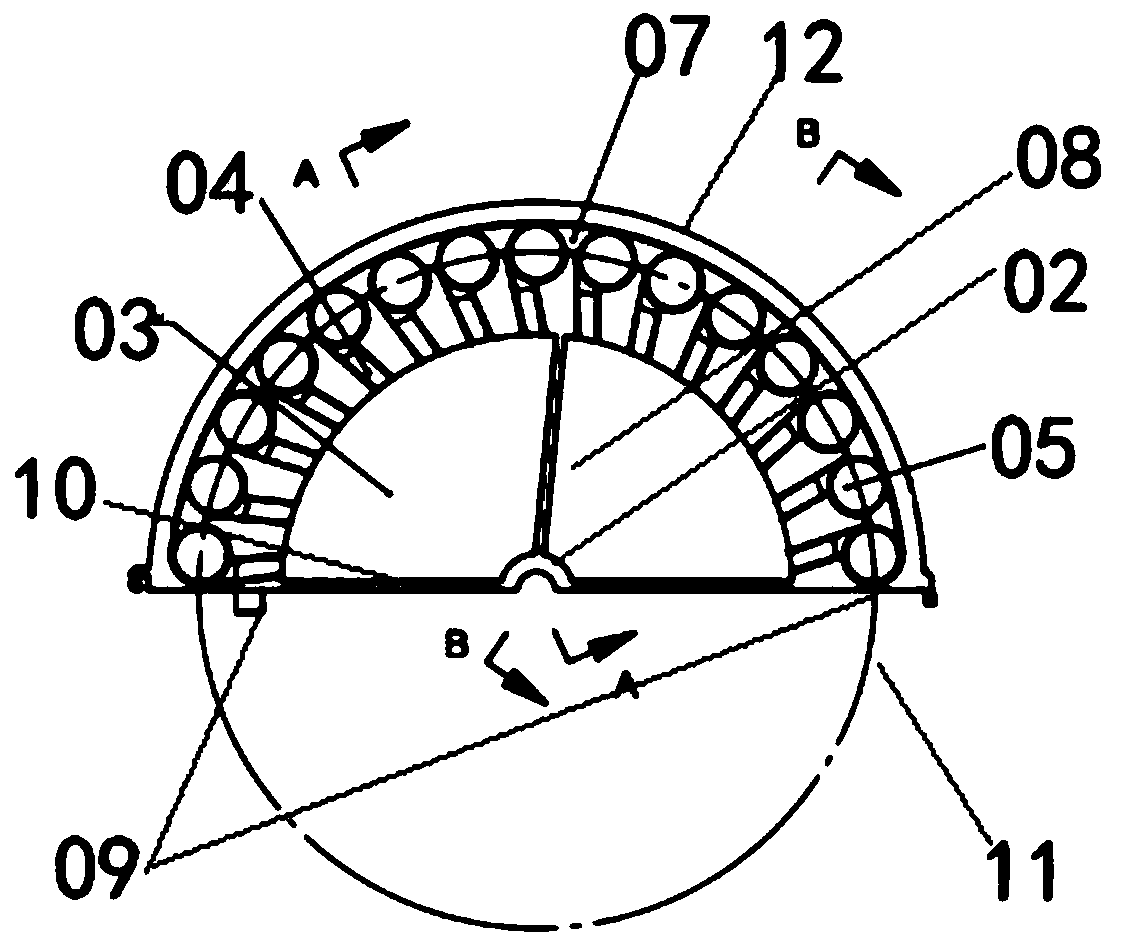

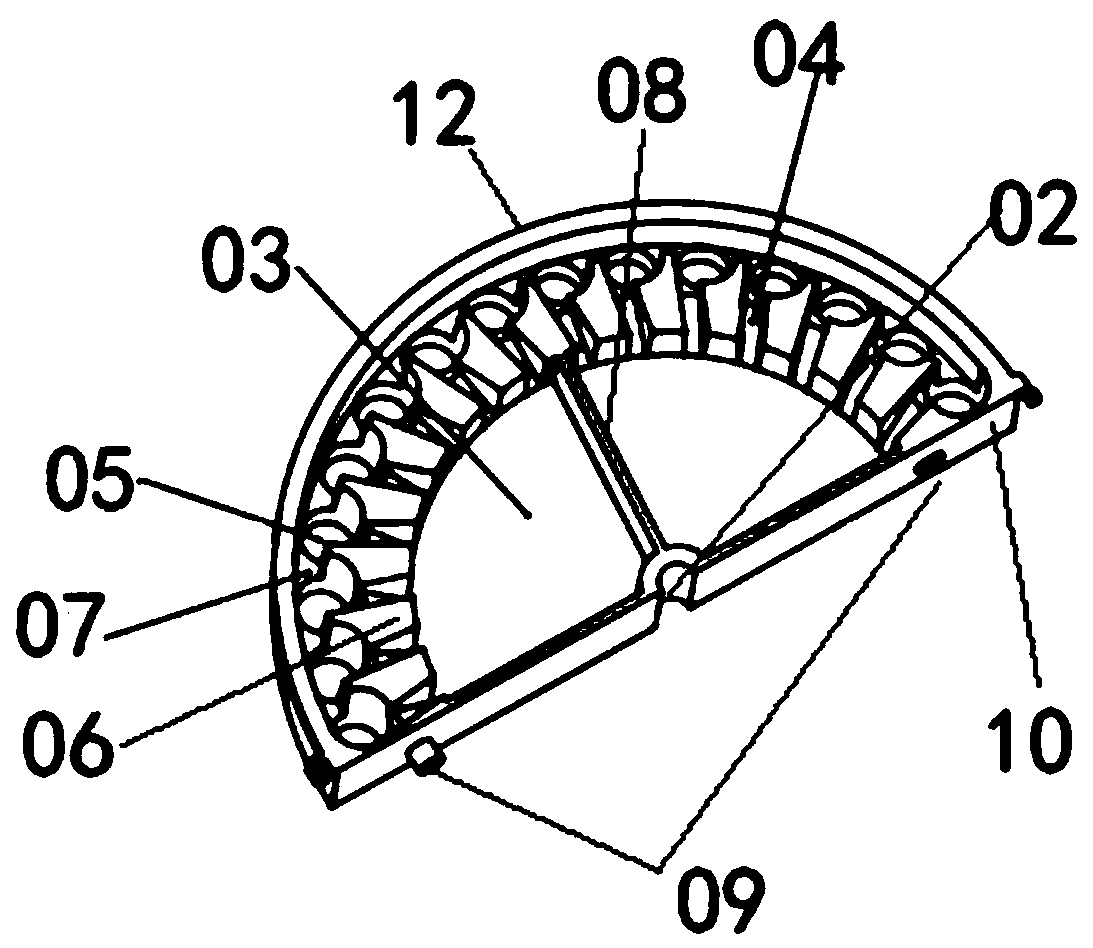

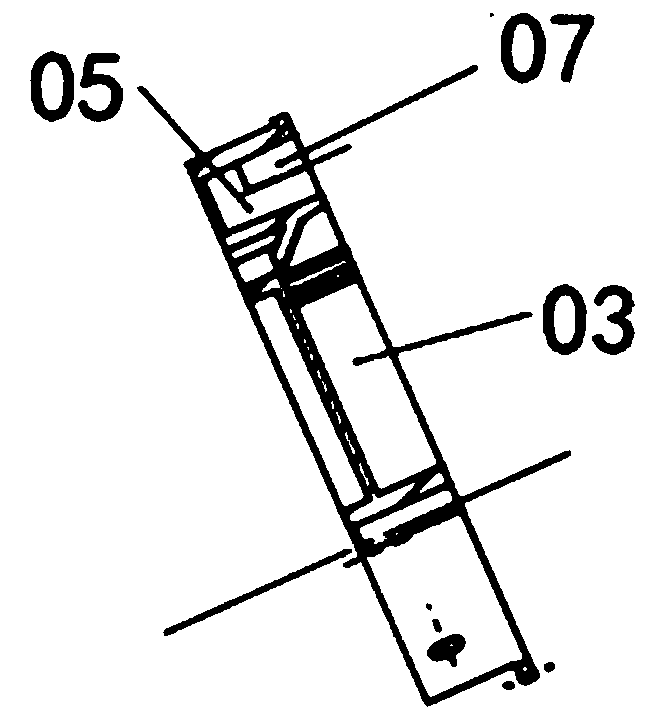

[0022] A semicircular liquid separation device such as figure 1 front view of figure 2 stereogram of image 3 and Figure 4 As shown in the cross-sectional diagram of , including 01 disk, 02 socket, 03 sample storage place, 04 liquid flow channel, 05 separation sample storage tank, 06 protrusion, 07 Unicom flow channel, 08 partition plate, 09 buckle, 10 Assembled board, the 01 disc includes 11 bases and 12 disc walls, the 02 jack is located at the center of the 01 disc and runs through the 01 disc, the 03 sample storage place is set around the 02 jack, the The 05 separation sample storage tank is set around the edge of the 01 disc, the 06 protrusion is set between the 03 sample storage place and the 05 separation sample storage tank, and the 04 liquid flow channel is formed between the adjacent 06 protrusions. The 10-piece board includes 09 buckles, and the 09 buckles are located at both ends of the diameter of the semicircular liquid separation device.

[0023] The semic...

Embodiment 2

[0026] A circular liquid separation device is formed by combining two semicircular liquid separation devices in Embodiment 1 through buckles.

[0027] When it is necessary to separate the liquid sample, install the liquid separation device on the centrifugal device through the 02 socket, place the liquid sample in the 03 sample storage place, turn on the centrifugal device, the 01 disc starts to rotate, and the samples in the 03 sample storage place are under centrifugal force. Under the action of the liquid, it moves toward the edge, and passes through the 04 liquid channel formed between the 06 protrusions, and finally flows into the 05 separation sample storage tank.

[0028] When there are enough liquid samples in the 05 separation sample storage tank, multiple samples overflowing from the separation sample storage tank are connected and mixed through the 07 communication channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com