Assembly method for large cabinet

An assembly method and cabinet technology, which are applied in tool storage devices, metal processing, metal processing equipment, etc., can solve the problems of time-consuming and laborious installation operations, missing parts, wrong installation, etc., to reduce repair operations, easy to carry, and install. Operation time-saving and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

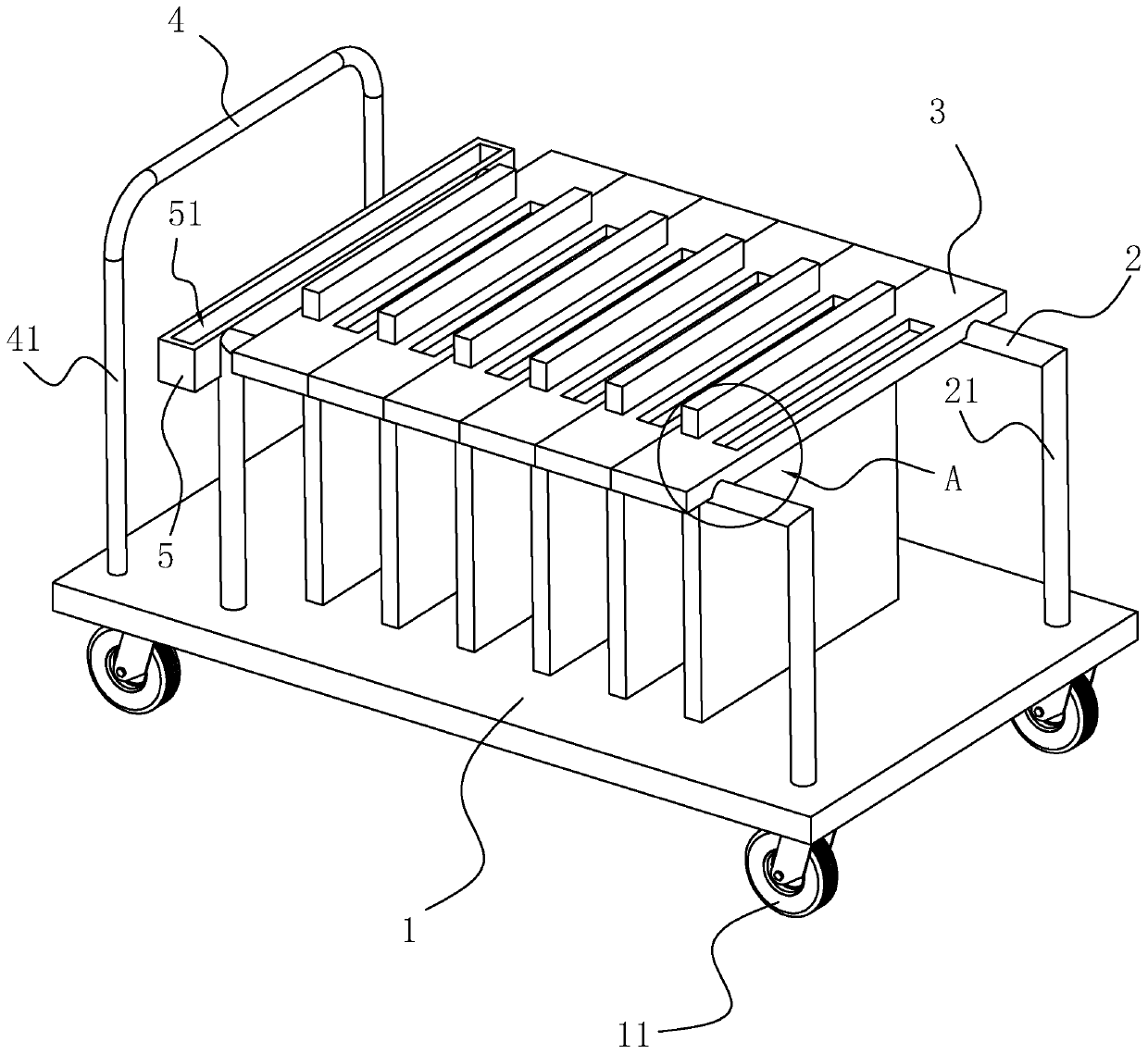

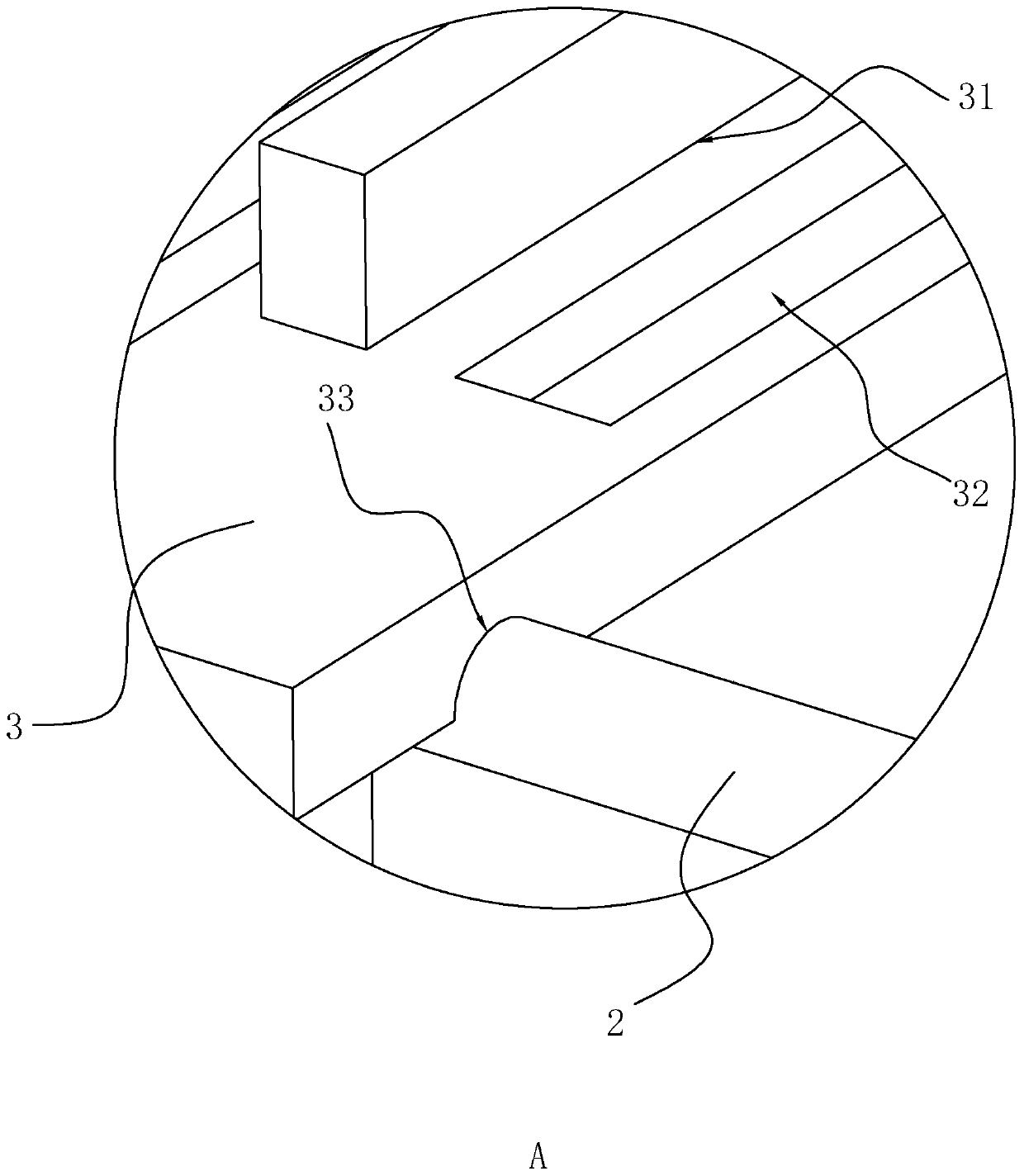

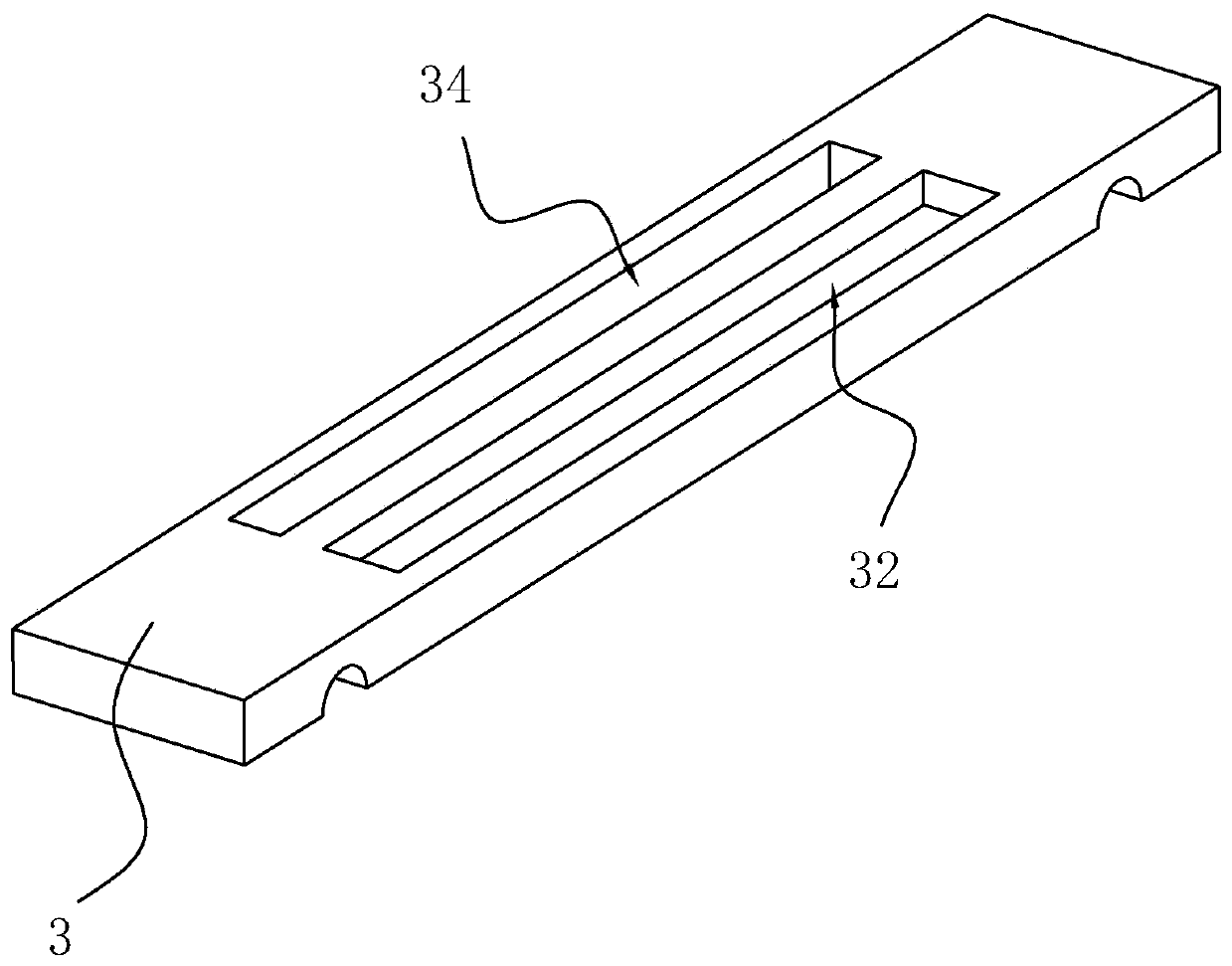

[0034] Embodiment 1: a kind of installation car, see attached figure 1 And attached figure 2 , including a bottom plate 1 arranged in a rectangular shape, a push rod arranged above one side of the top plate, two support rods 2 arranged above the bottom plate 1, several support blocks 3 arranged above the bottom plate 1 and four corners arranged at the bottom of the bottom plate 1 A universal wheel 11; the axial direction of the push rod is horizontally arranged and the axial direction of the push rod is parallel to the side of the bottom plate 1 near the push rod; the bottom two ends of the push rod are fixedly connected with two connecting rods 41, and one end of the bottom of the connecting rod 41 It is fixedly connected to the top of the bottom plate 1; the axis direction of the support rod 2 is arranged horizontally and the axis direction of the support rod 2 and the axis direction of the push rod 4 are parallel to each other. Both ends of the bottom of the support rod 2...

Embodiment 2

[0038] Embodiment 2: A method for assembling a large cabinet, comprising the following steps:

[0039] a. Main frame assembly: first assemble the main frame of the cabinet to realize the construction of the main frame;

[0040] b. Parts classification: group according to different cabinets, list the parts that make up the cabinet, according to front door, back door, left door, right door, fixed tray, sliding tray, power supply bracket, cable management ring, cable management frame, L Classify brackets and extended beams, each single component represents a group, each component group includes the single component and the bolts, nuts and washers required to install the component, and the number of groups Count and sort the groups in the order of installation;

[0041] c. Arrange the installation platform and parts receiving platform: build the installation platform and parts receiving platform. There are four installation platforms and parts receiving platforms. The installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com