Method and device for direct crystallization of polycondensate

A polycondensation and crystallization technology, applied in chemical instruments and methods, lighting and heating equipment, chemical/physical processes, etc., can solve problems such as limiting the scope of use, and achieve the effect of omitting the crystallization step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

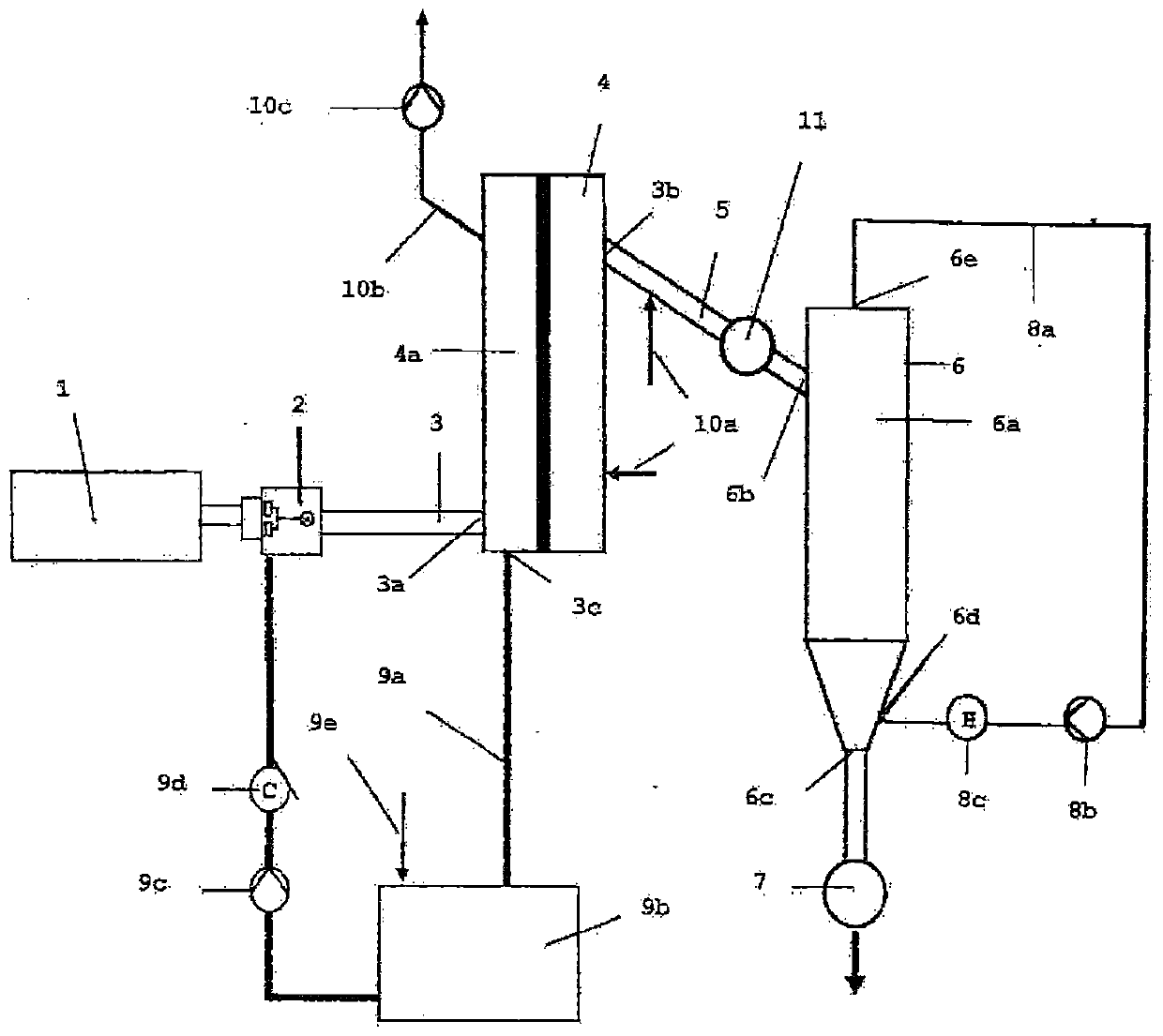

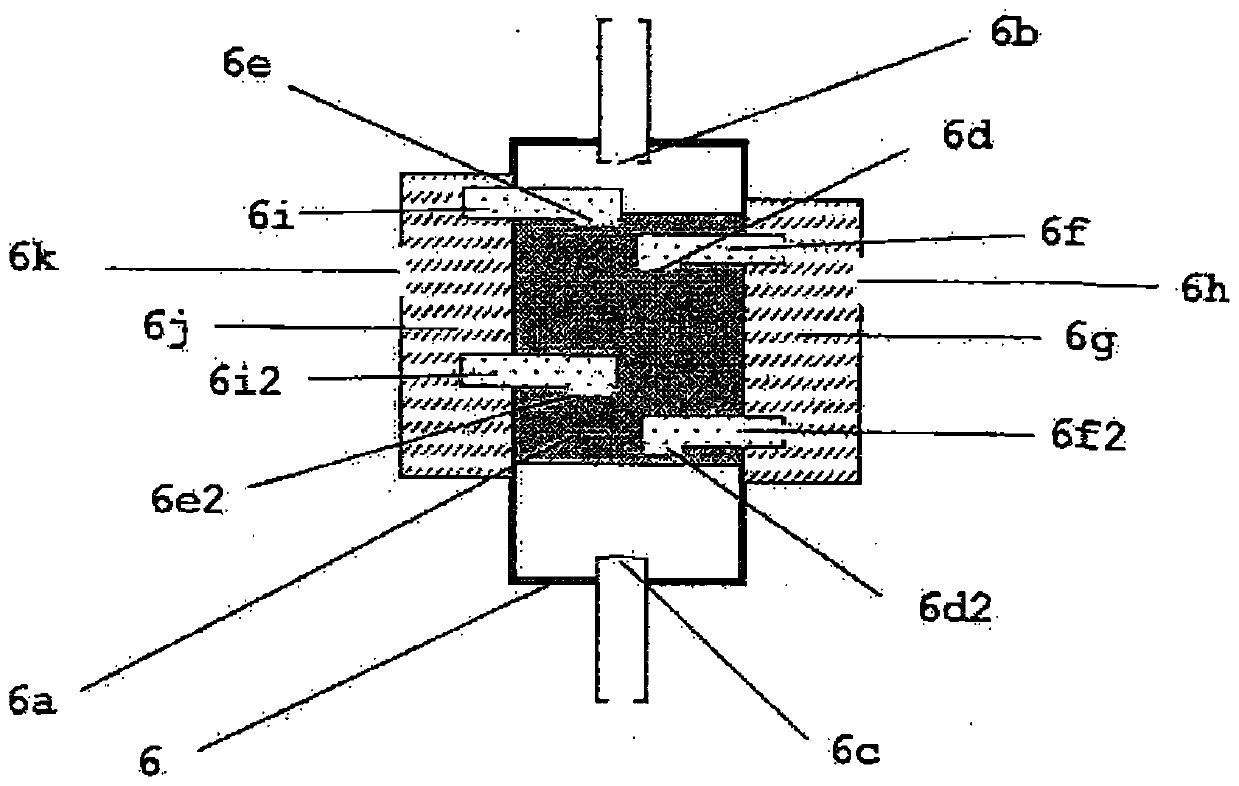

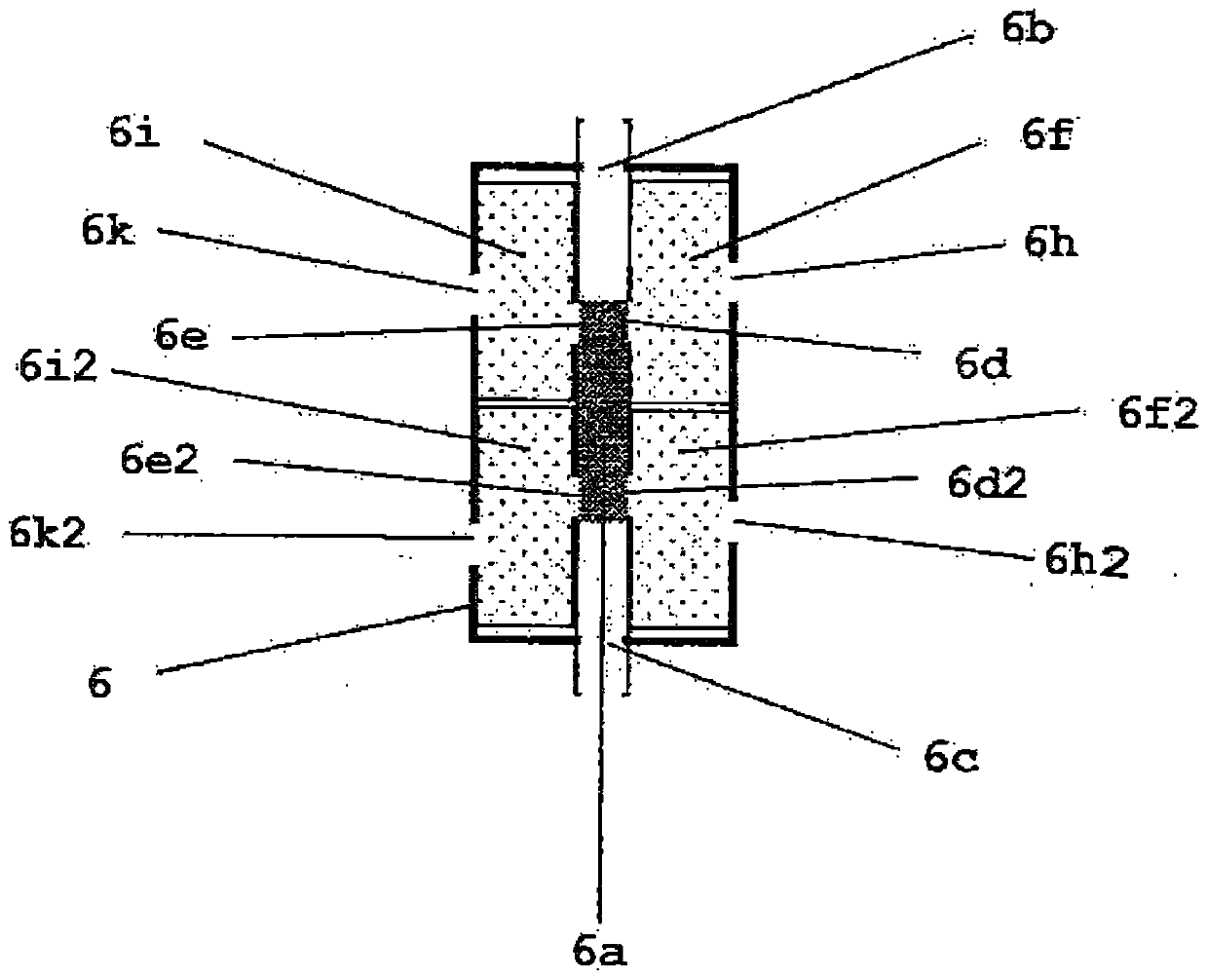

Method used

Image

Examples

Embodiment 1

[0187] Process 10t / h of 2.5% initial crystallinity and T GR = PET pellets with an entry temperature of 140°C.

[0188] If 3000kg / h (X=0.3) with T Gas = Nitrogen at 220°C, then heat up to T PH = 171°C and the crystallinity increased to 32.5%, which corresponds to T KR = 18.7°C temperature increase due to crystallization. For heat of crystallization q, 115 J / g was used for 100% crystallinity, and for heat capacity c, 1.84 J / g / K was used.

[0189] T Gas Therefore than T GR +T KR 61.3°C higher, and X*(T Gas -T GR -T KR ) at 18.4°C, and T PH Than T GR +T KR 12.3°C higher.

[0190] The gas velocity at the gas outlet is 0.36 m / s, whereby fixed bed conditions exist. This results in a pressure drop of 34mbar. The residence time of the pellets in the treatment chamber was 16.3 minutes.

Embodiment 2

[0192] If the amount of gas in Example 1 is increased to 6000kg / h (X=0.6), then the temperature is raised to T PH = 181.2°C. Increased degree of crystallinity and thus T KR constant.

[0193] T Gas still better than T GR +T KR 61.3°C higher, and X*(T Gas -T GR -T KR ) is 36.8°C, and T PH Than T GR +T KR 24.2°C higher.

[0194] The gas velocity at the gas outlet is 0.73 m / s, whereby fixed bed conditions are still present throughout. This produces a pressure drop of 66mbar.

[0195] This example shows better heating at higher gas quantities in a fixed bed.

Embodiment 3

[0201] If the treatment chamber of Example 1 is divided into 4 zones 0.3 m high and the product is treated in each zone with a gas quantity of 6000 kg / h (X total = 2.4), the temperature is raised to T PH = 206°C.

[0202] at T KR In the case of constant, X*(T Gas -T GR -T KR ) is 166°C, T PH Than T GR +T KR 47.3°C higher.

[0203] The average gas velocity at the gas outlet was 0.79 m / s, whereby fixed bed conditions were always present. A pressure drop of 71 mbar results.

[0204] This example shows better heating in the multi-stage mode of operation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com