Cooling module assembly and vehicle

A technology of cooling module and assembly, which is applied in the layout of vehicle components and power unit cooling combination, power unit, etc. Effect and safety and stability guarantee, simple and convenient installation, stability guarantee effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

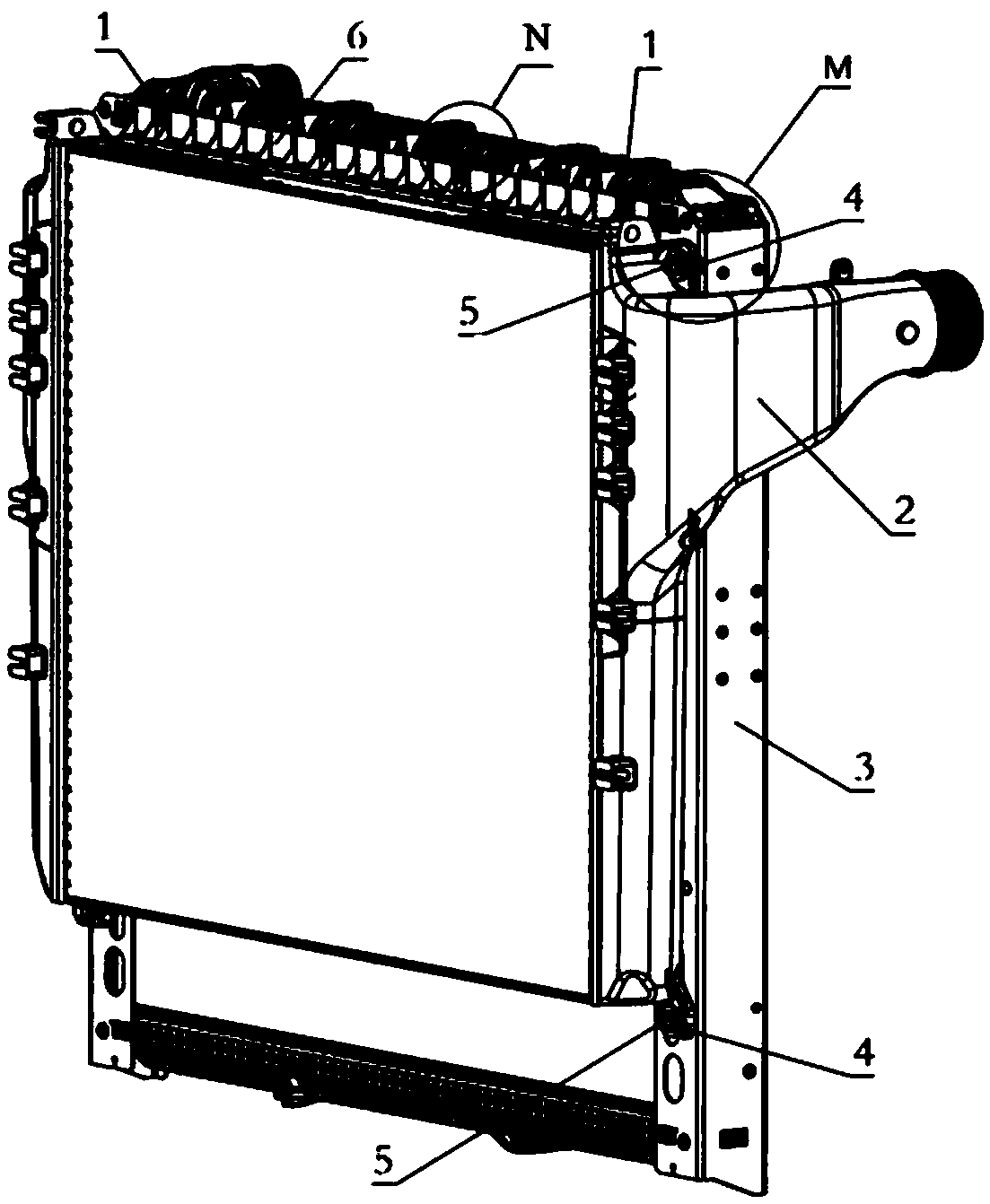

[0055] Such as figure 1 As shown, the cooling module assembly is mainly composed of a radiator 3, an intercooler 2, a windshield 6, a clip 1, a flexible connection structure 4, and the like.

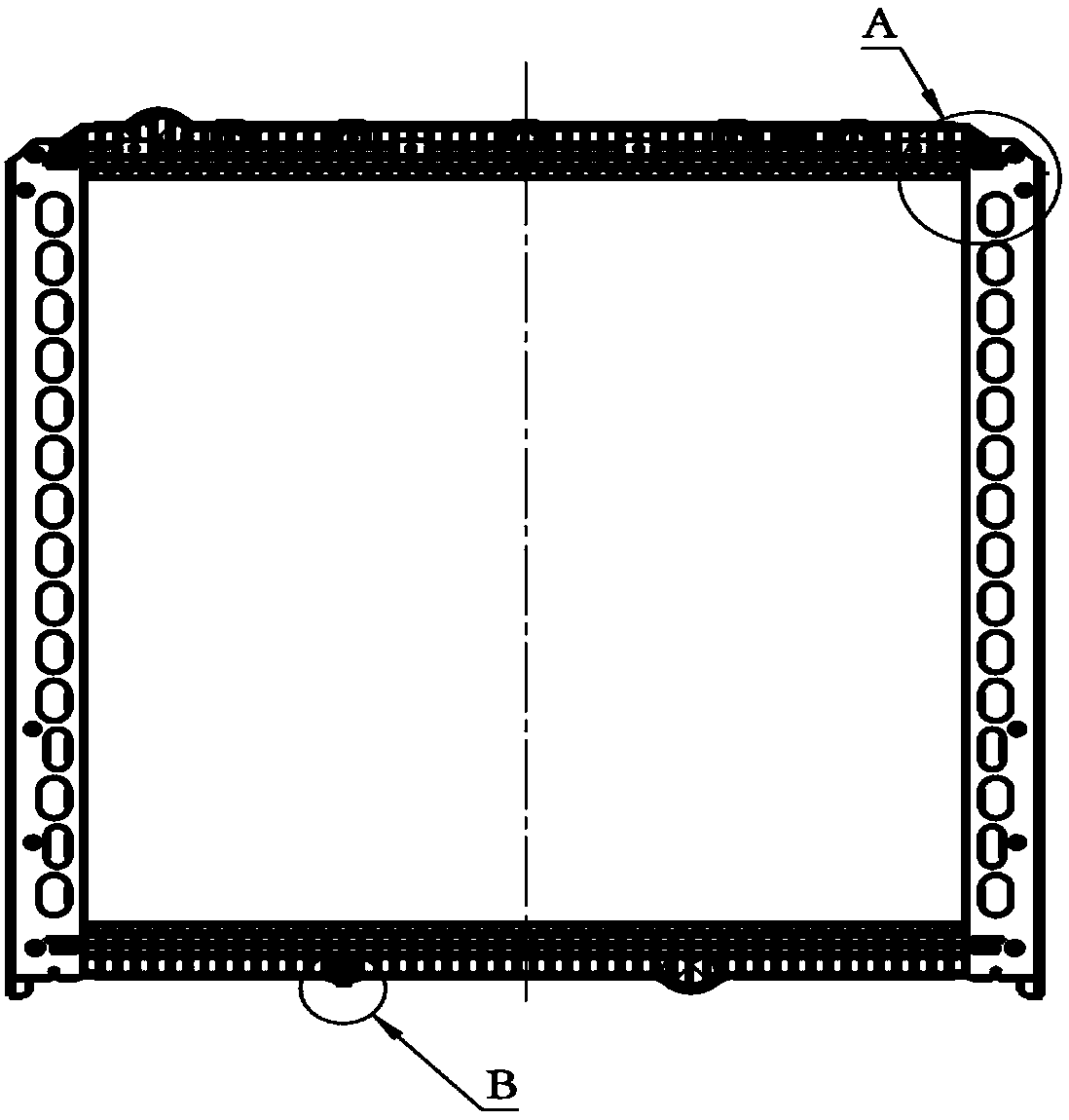

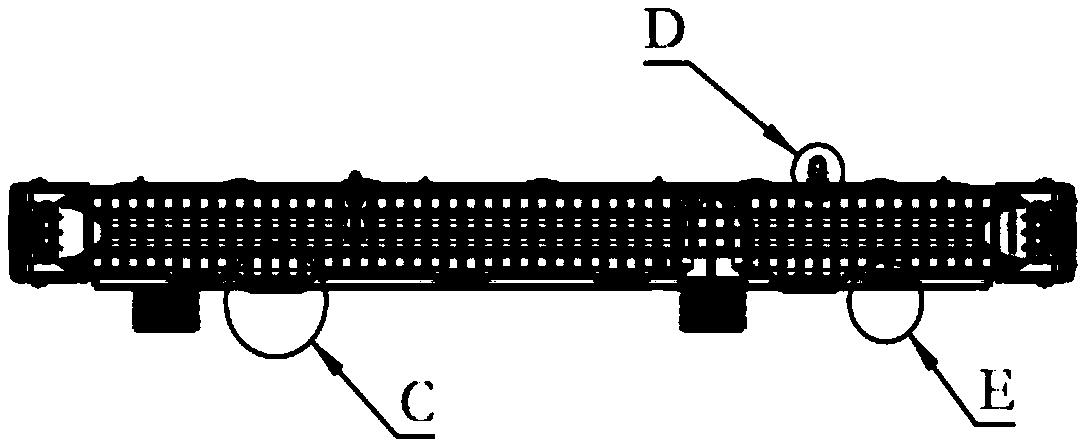

[0056] The core body elevation of the radiator is stacked with the core body elevation of the intercooler, and the left and right sides of the intercooler are rigidly connected to the radiator guard plate; the other side is connected and installed through a flexible connection structure, so that the The components between the radiator and the intercooler have a certain displacement space to eliminate the thermal stress and possible vibration stress caused by the large temperature difference between the left and right air of the intercooler. Such as figure 2 As shown, the radiator 3 adopts a plastic water chamber and a wide guard plate structure, and the vent 7 is designed on the guard plate, which improves the cooling performance and reliability, effectively protects the core body and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com