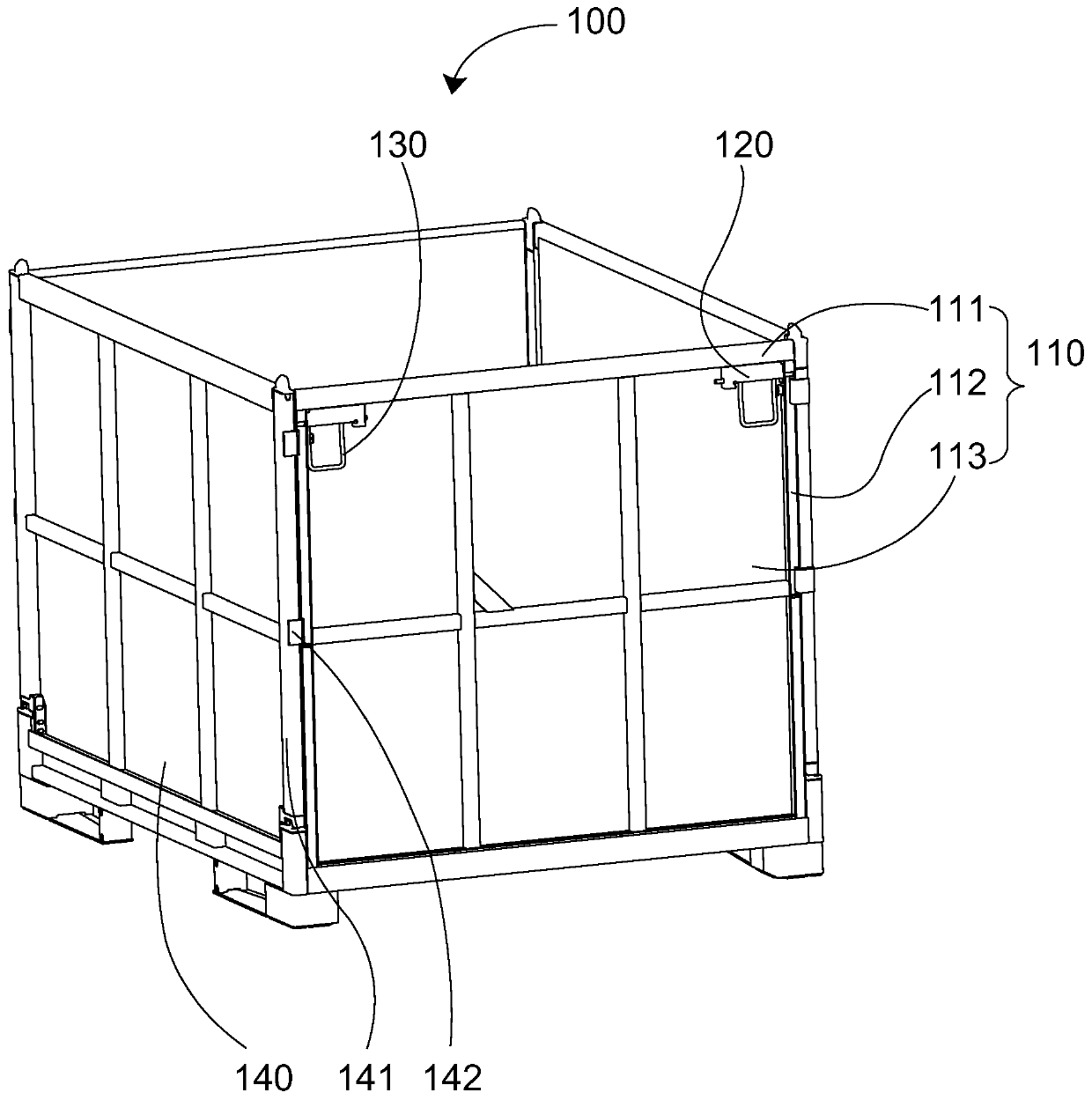

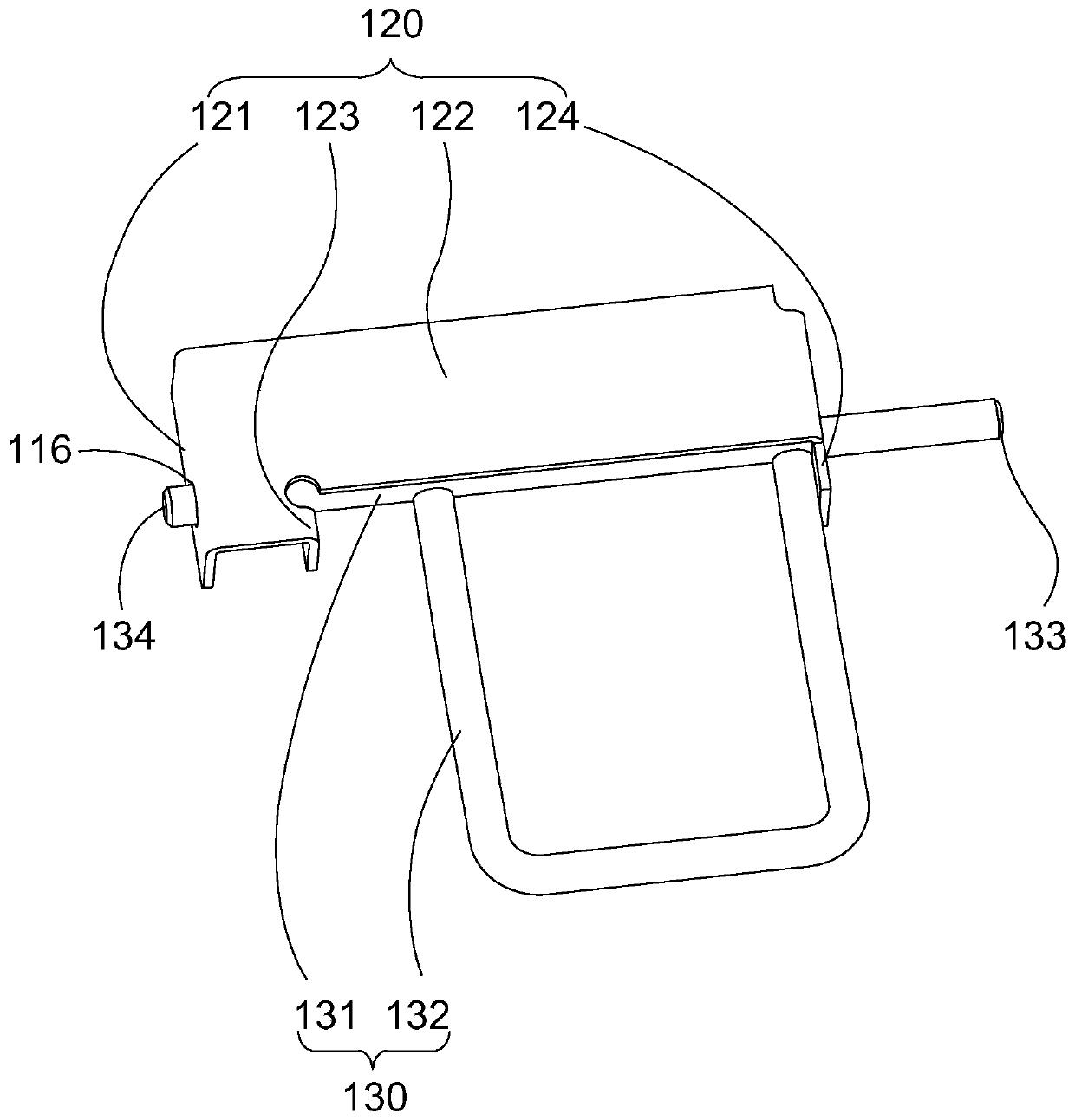

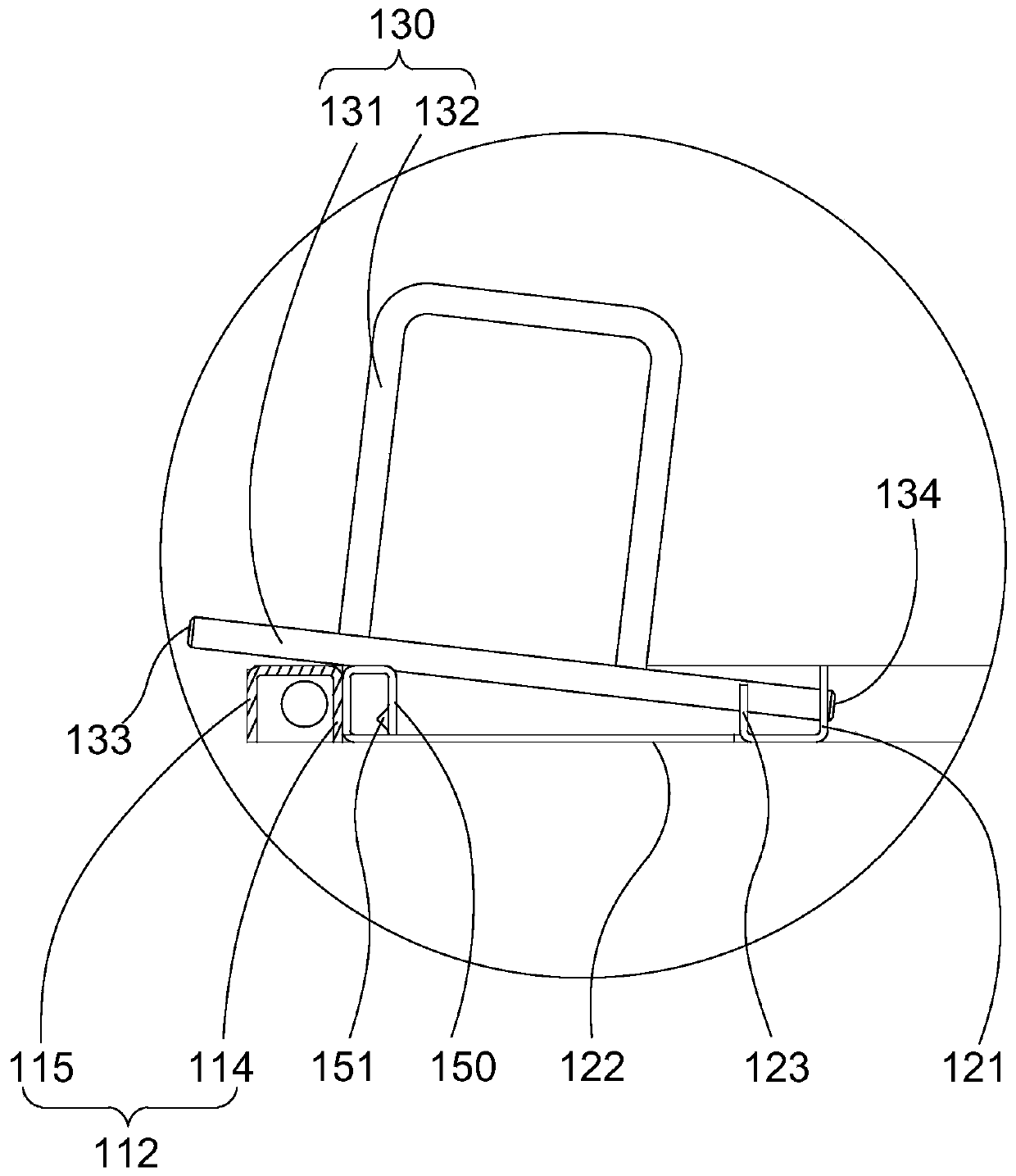

Pallet box

A pallet box and support technology, applied in the field of machinery, can solve the problems of affecting operation safety, difficult processing, and lack of fixed locks, and achieve the effects of not destroying the coating, good safety, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In the following description, a lot of specific details are given in order to provide a more thorough understanding of the present invention. However, it is obvious to those skilled in the art that the embodiments of the present invention can be implemented without one or more of these details. In other examples, in order to avoid confusion with the embodiments of the present invention, some technical features known in the art are not described.

[0057] It should be noted that the terms "upper", "lower", "front", "rear", "left", "right", "inner", "outer" and similar expressions used in this article are for illustration only Purpose, not limitation.

[0058] The ordinal words such as "first" and "second" quoted in the present invention are merely identifications and do not have any other meanings, such as a specific order. Also, for example, the term “first component” itself does not imply the existence of “second component”, and the term “second component” does not imply ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap