Roof and gable joint

A gable and node technology, applied in the direction of roof, roof cladding, roof insulation materials, etc., can solve problems such as roof leakage, affecting the use effect and service life of the roof, and sealing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

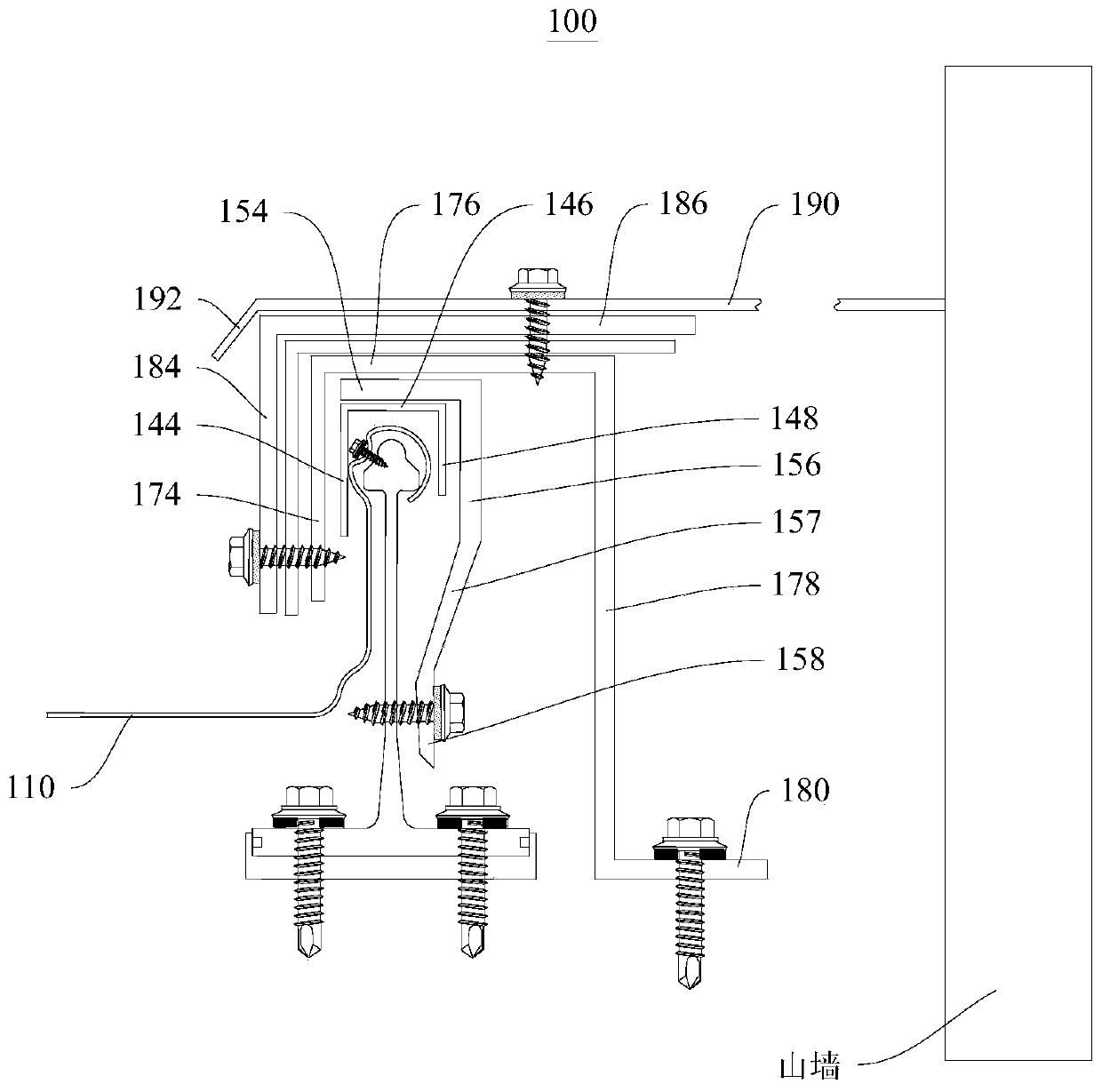

[0031] Please refer to figure 1 , figure 1 Shown is a schematic diagram of the separation and connection structure of the roof gable node 100 . This embodiment provides a roof gable joint 100, which can ensure the waterproof effect of the roof without destroying the structural integrity of the roof, and improve the use comfort of the roof.

[0032] At present, for the edge joints at the end of the gable wall, the general method is to simply connect and fix the gable cover plate flashing and the edge plate rib of the roof installation plate with self-tapping screws. The nail holes penetrate the inside and outside of the roof, which is prone to seal failure. Therefore, there is a great possibility of roof leakage, which greatly affects the use effect and service life of the roof. However, the roof gable node 100 provided in this embodiment can well solve the above problems.

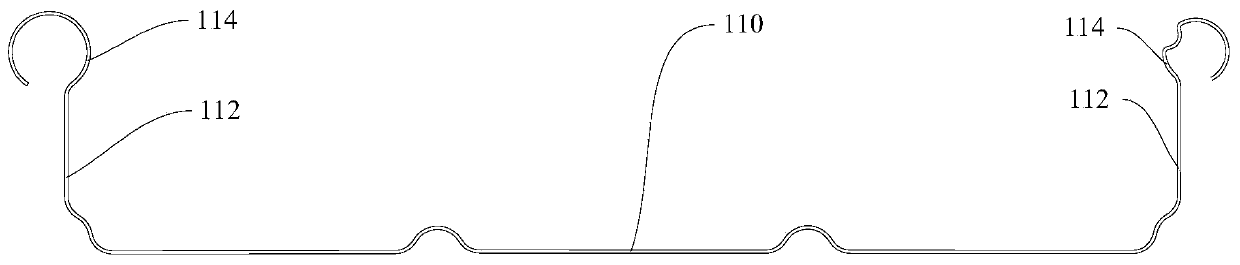

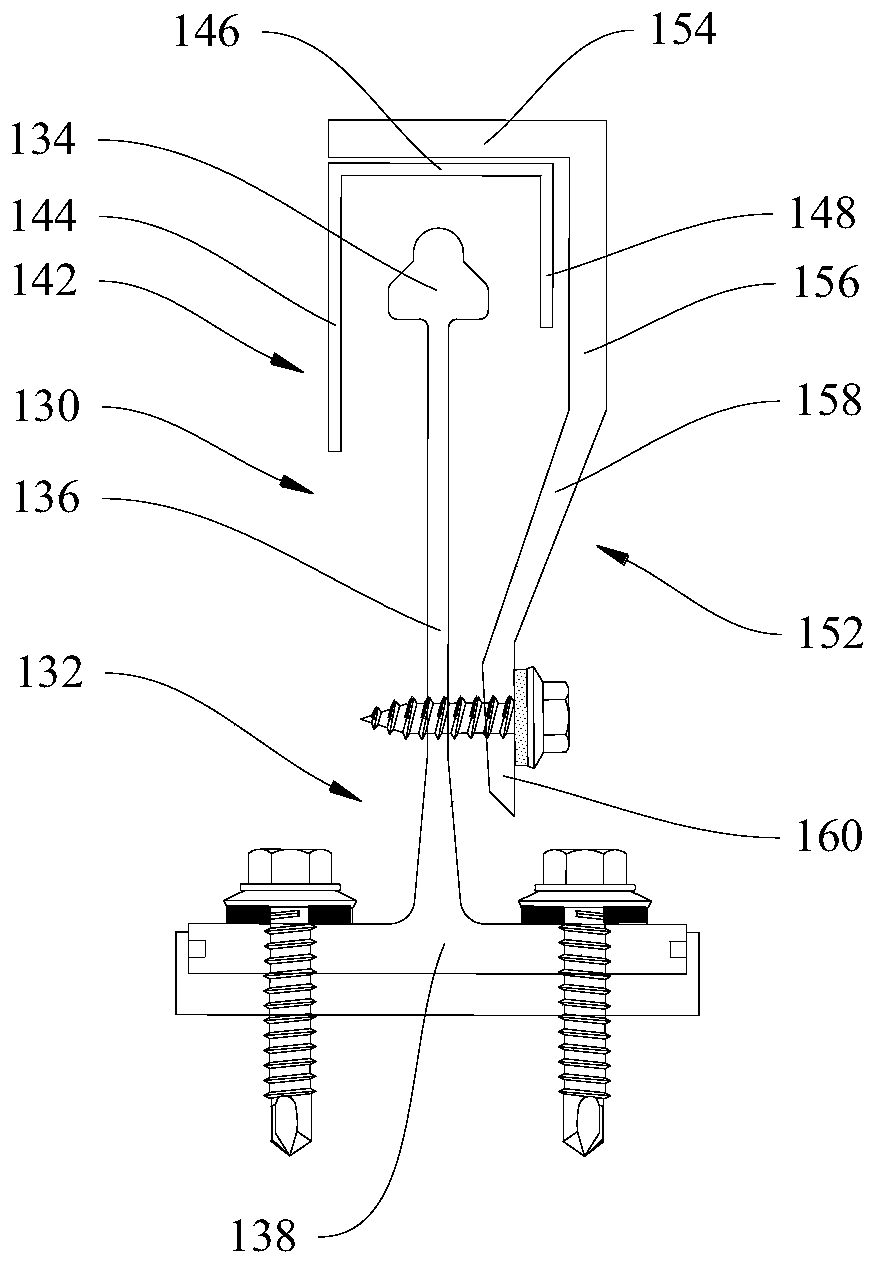

[0033] Please refer to figure 1 , figure 2 , image 3 and Figure 4 , figure 2 Shown is a struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com