Insulator clamping jaw

A technology of insulators and grippers, which is applied in the direction of cable installation devices, electrical components, overhead lines/cable equipment, etc., and can solve problems affecting the smooth progress of maintenance and monitoring work, the degree of opening and closing of difficult arc-shaped grippers, and the reduction of gripping efficiency, etc. problems, to achieve the effect of improving gripping efficiency, convenient operation, and stable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

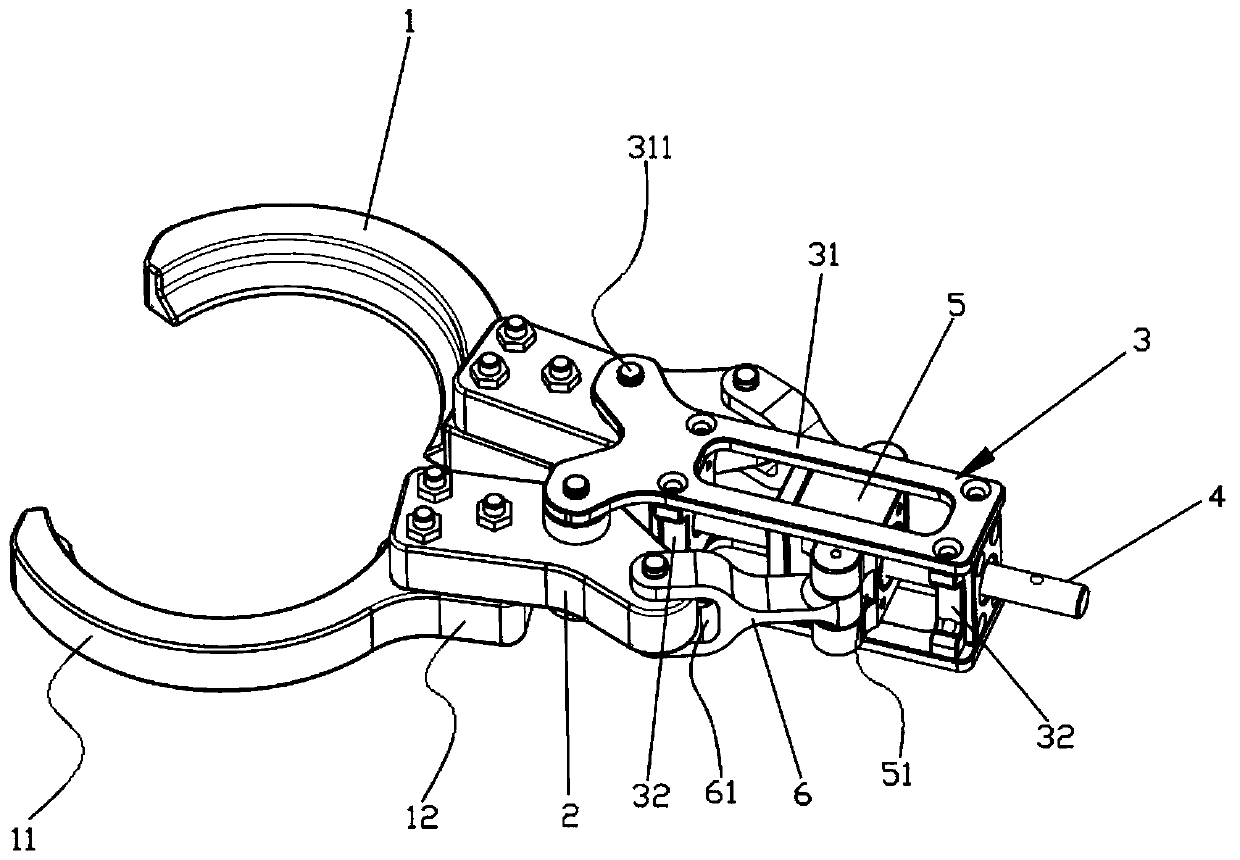

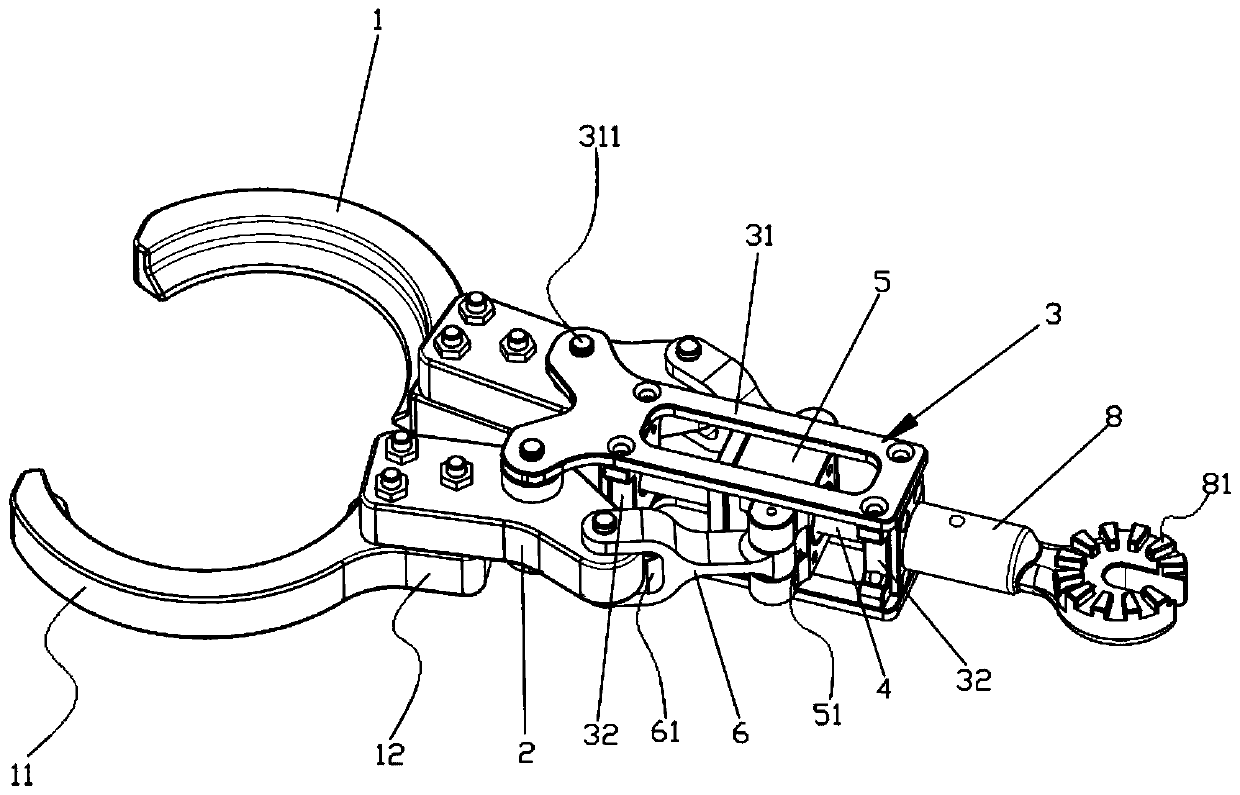

[0041] The above is the first embodiment of an insulator gripping claw hand provided by the embodiment of the present application, and the following is the second embodiment of an insulator gripping claw hand provided by the embodiment of the present application. For details, please refer to Figure 1 to Figure 3 .

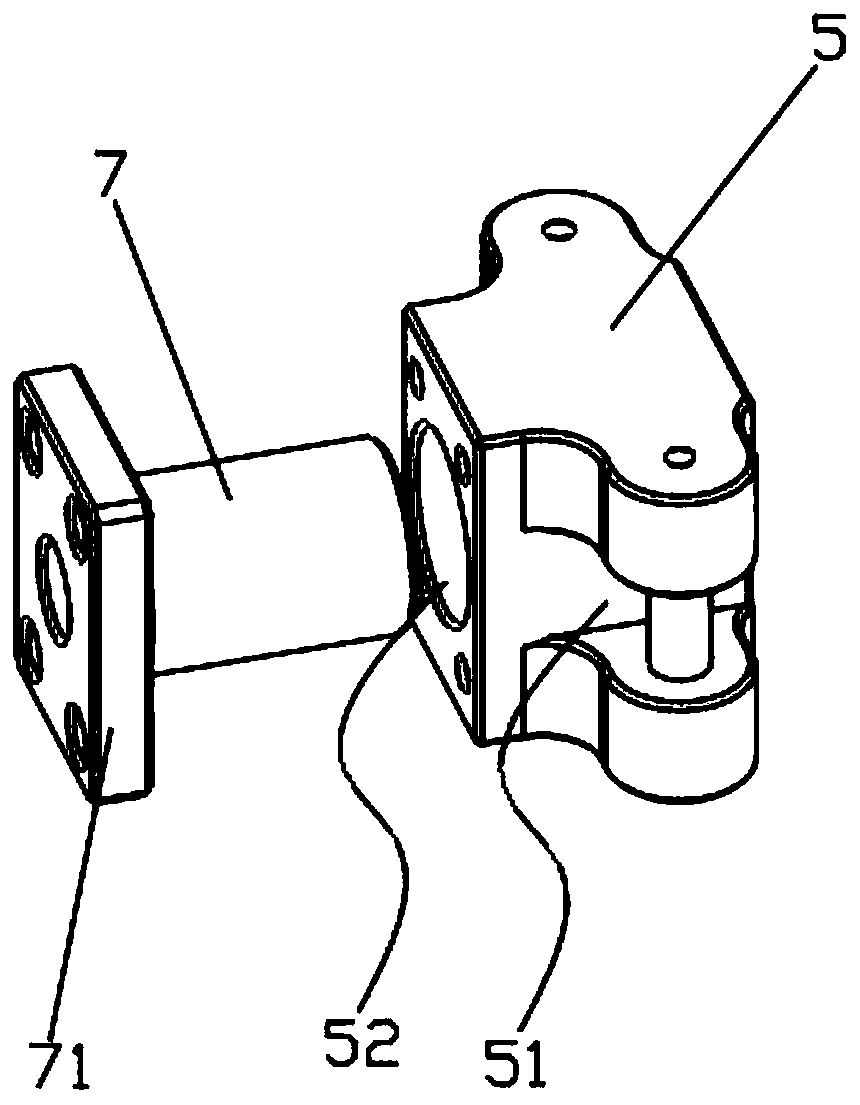

[0042] An insulator gripping claw hand, comprising: a connecting frame 3, two claws 1, two claw arms 2, two connecting rods 6, a screw rod 4 and a slider 5; two claw arms 2 are rotatably mounted on the connecting frame 3 On the first end, and symmetrically distributed, the first ends of the two jaw arms 2 are connected to the jaws 1 respectively, and the second ends are respectively connected to the slider 5 through the connecting rod 6; the connecting frame 3 is provided with an installation cavity; The block 5 is slidably installed in the installation cavity; the screw rod 4 is rotatably installed on the connecting frame 3, and moves through the sliding block 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com