Cleaning process for solving patterning collapse of advanced node

A patterning and node technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of ineffective cleaning methods and drying processes, production process influence, patterned structure collapse, etc., to avoid The effect of graphical collapse of tension drawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

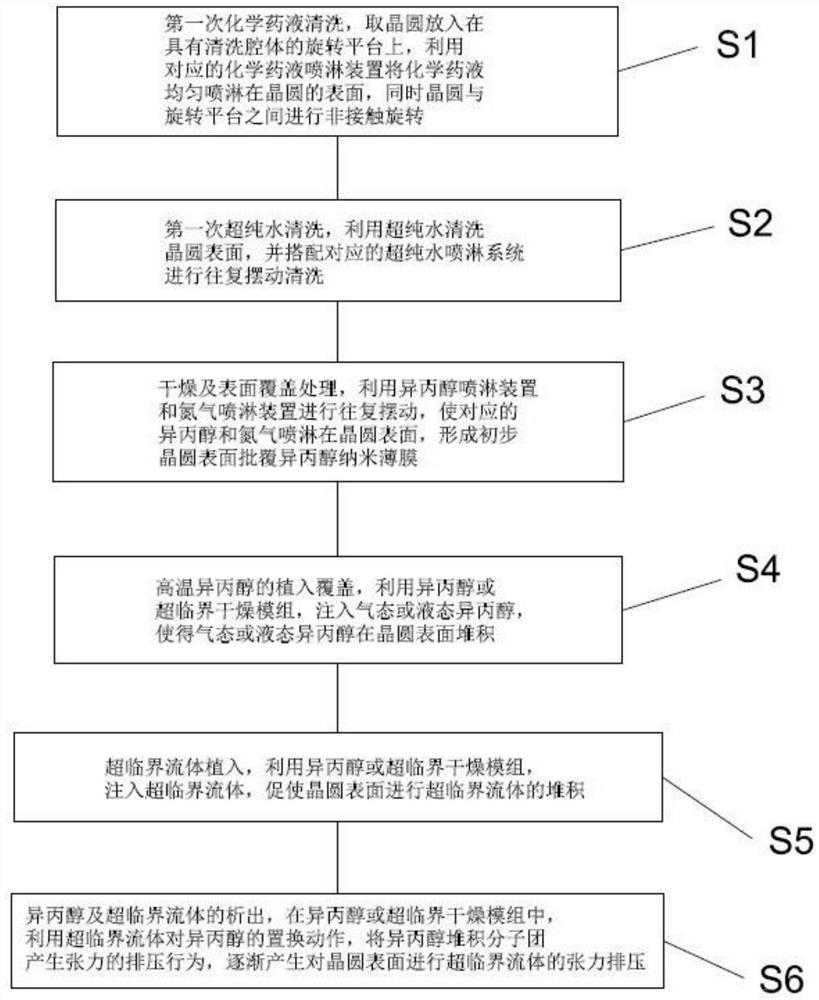

Method used

Image

Examples

Embodiment approach

[0040] Further, as a preferred embodiment, during the first cleaning process of the chemical liquid, nitrogen gas can be passed through, and the chemical liquid can be subjected to sonic vibration and nitrogen jet flow so that the chemical liquid molecules can be finely After chemical treatment, the refined chemical liquid molecules can be more evenly distributed on the surface of the wafer under the action of nitrogen gas, which can effectively improve the cleaning effect. Secondly, the chemical liquid can be heated and degassed, which can maintain the stability of the chemical liquid and improve the cleaning efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com