Patents

Literature

30results about How to "Achieve stability control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Image vibration-compensating apparatus and method thereof

InactiveUS20070132852A1Reduce calculation requireReasonable priceTelevision system detailsPicture signal generatorsMotion computationSelf adaptive

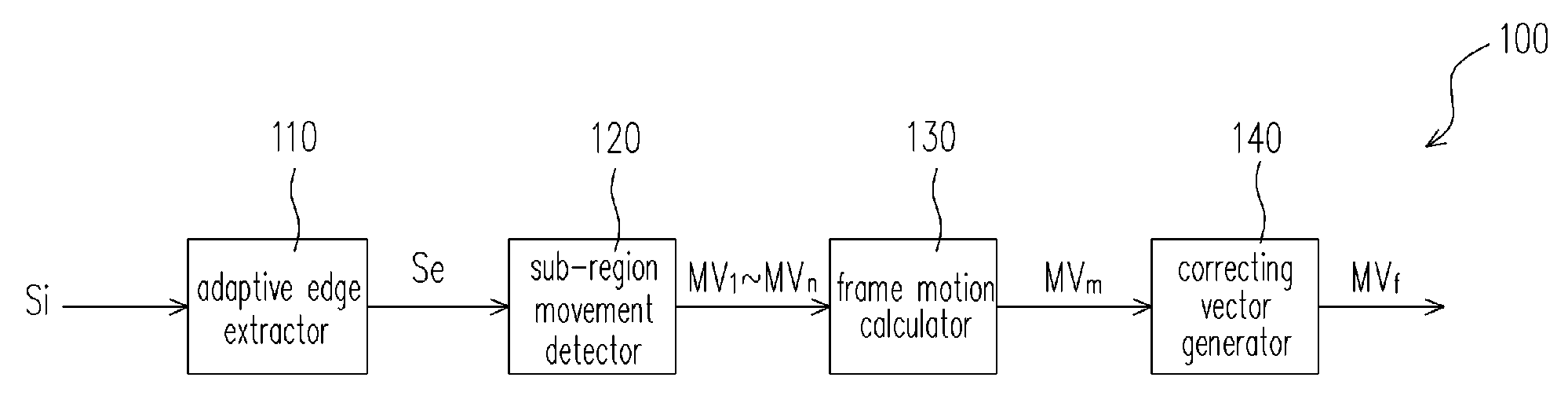

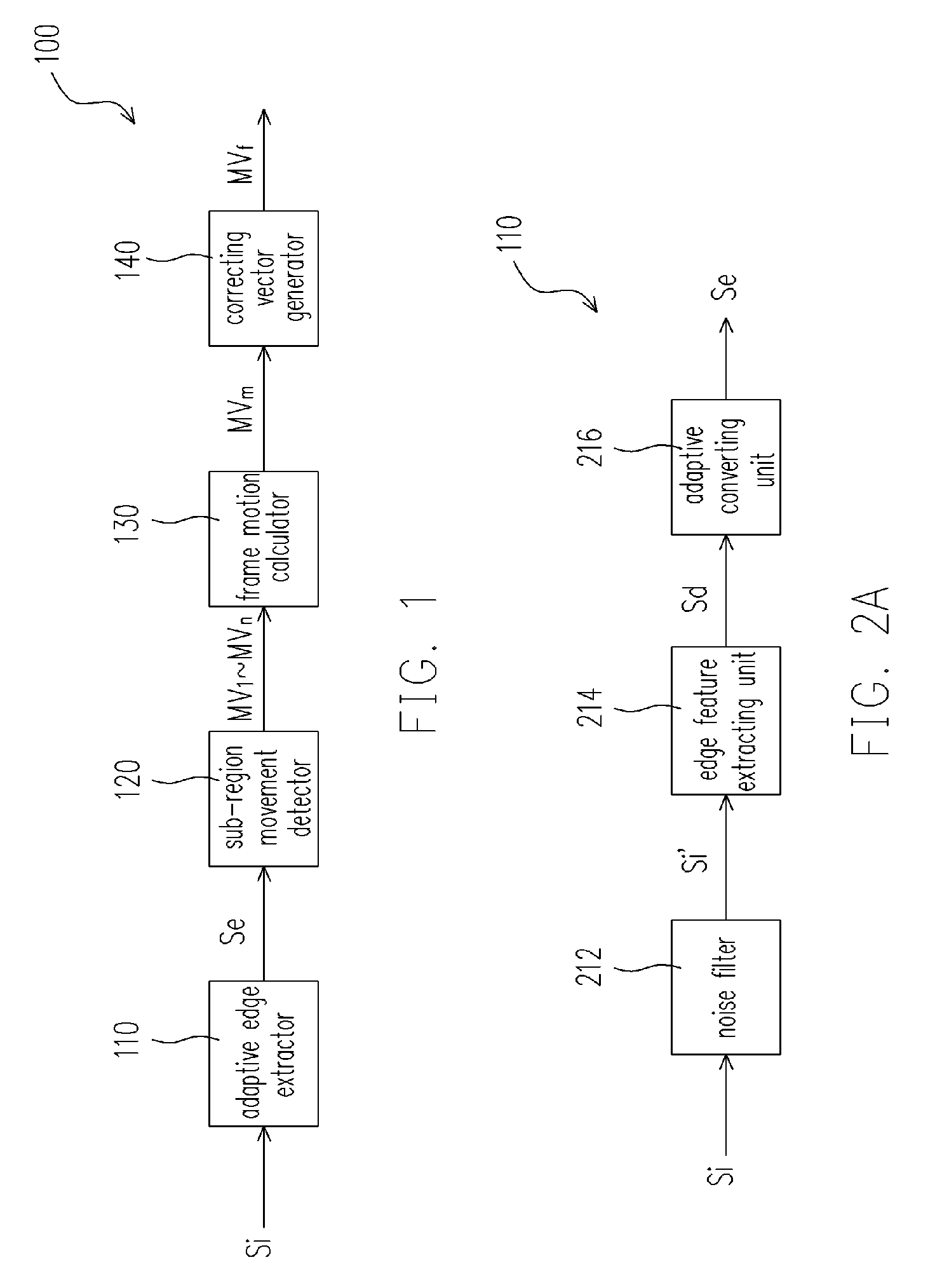

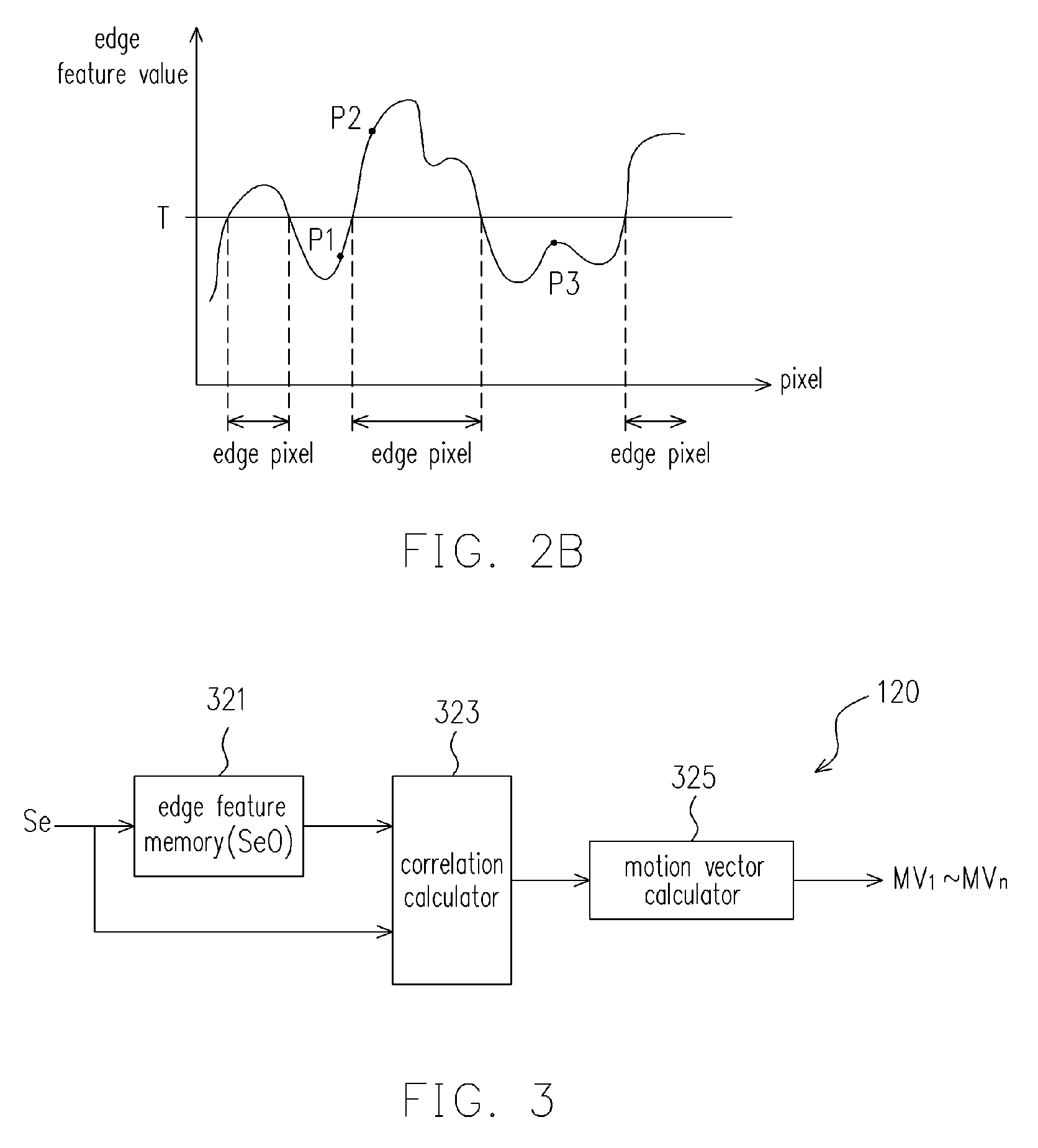

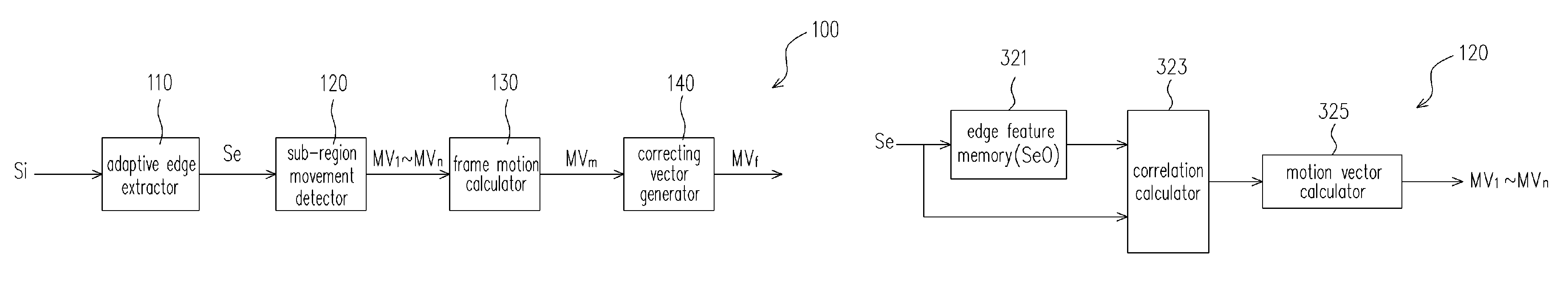

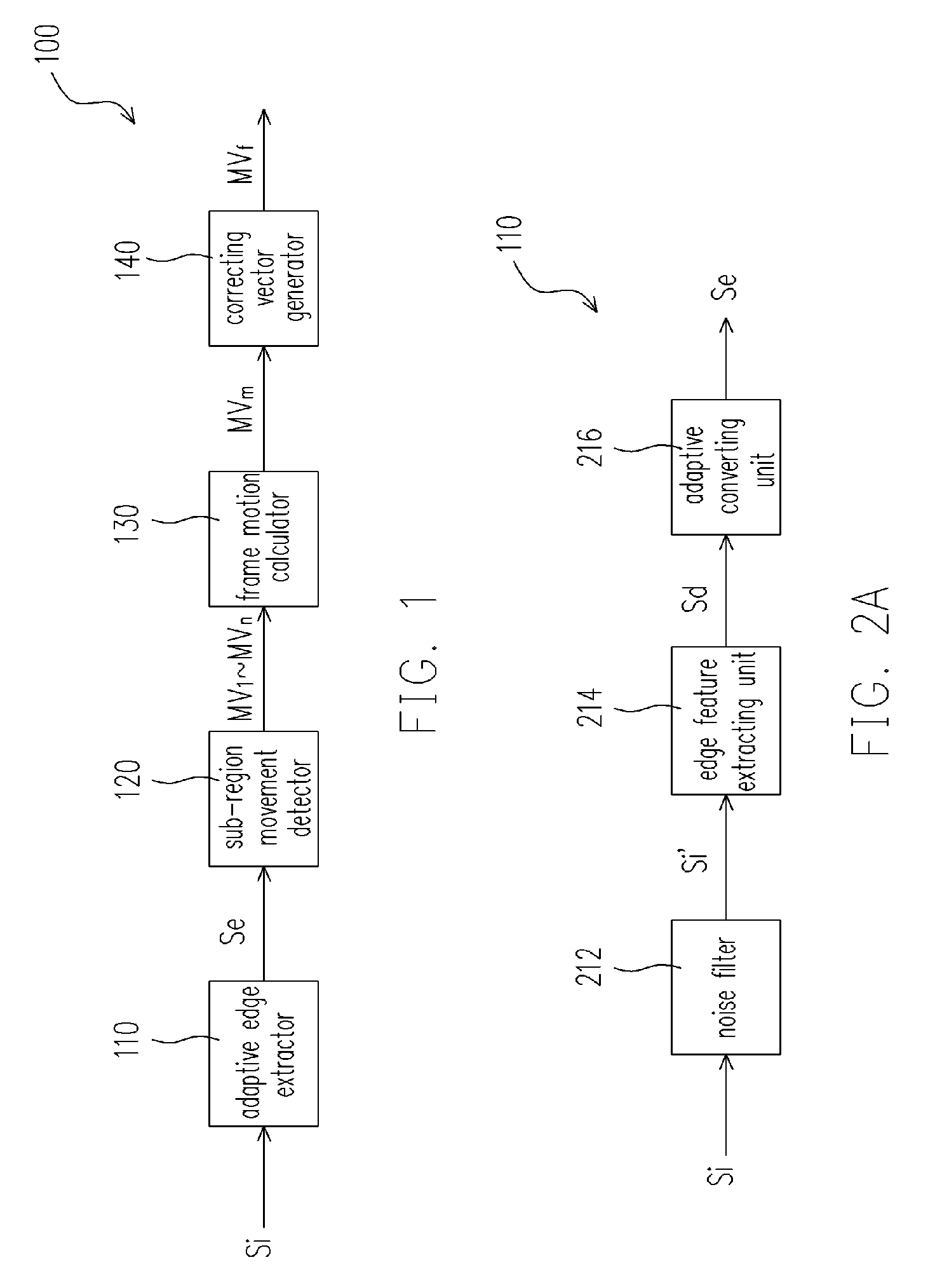

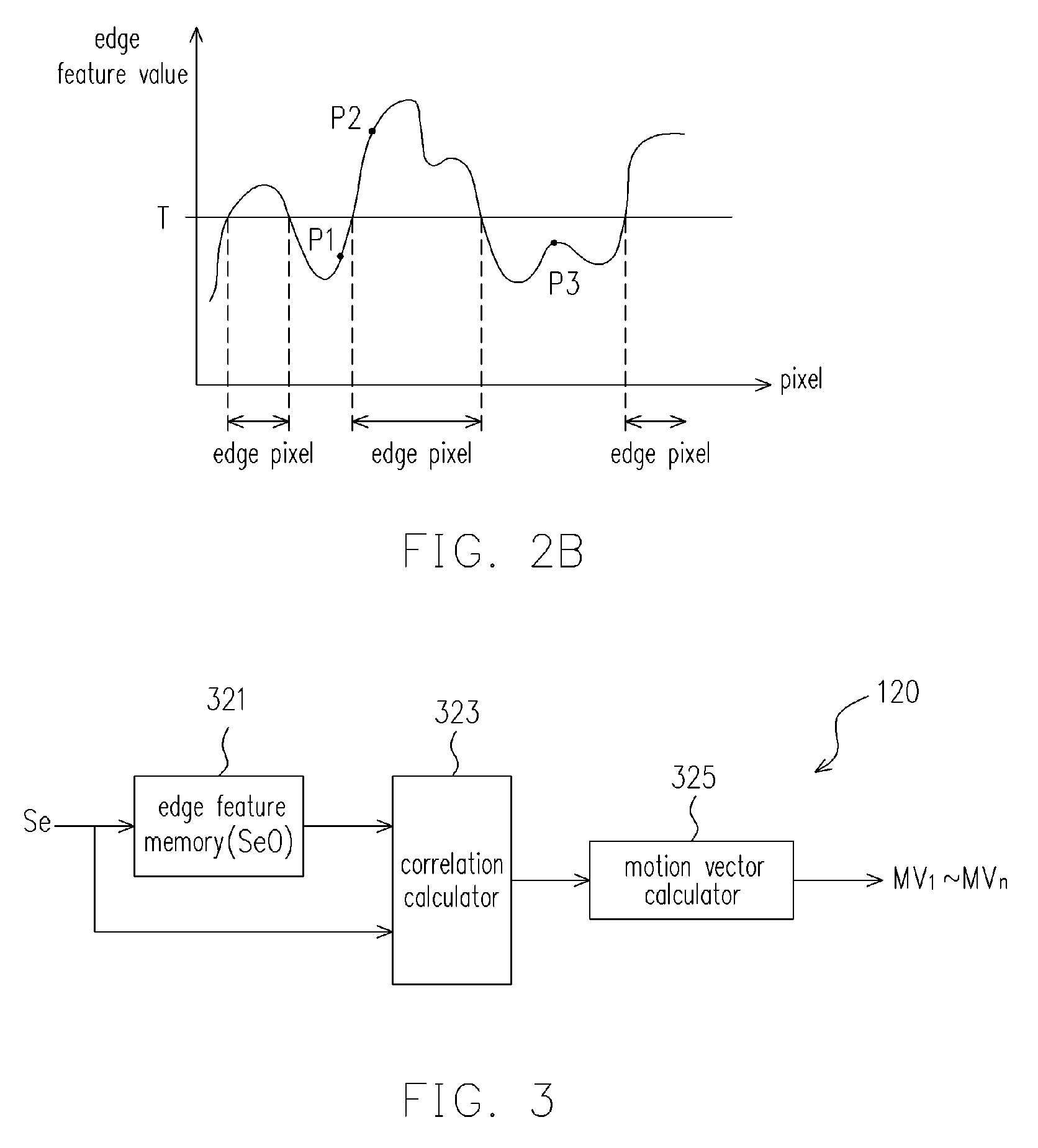

An image vibration-compensating apparatus and a method thereof are provided. The apparatus and the method are applied in an image-capturing apparatus, such as a digital still camera (DSC) or digital video recorder (DVR), for compensating image vibration when capturing an image. The image vibration-compensating apparatus comprises an adaptive edge extractor, a sub-region movement detector, a frame motion calculator, and a correcting vector generator. The image vibration-compensating apparatus analyses the difference between the current image and the previous image, and outputs the correcting motion vector to achieve the function of image vibration-compensation. In the image vibration-compensating method, an accumulate compensation mode is used to prevent fast motion of an image frame which will cause discomfort of the user's eyes when a relatively large image vibration occurs in a short period.

Owner:NOVATEK MICROELECTRONICS CORP

Image vibration-compensating apparatus and method thereof

InactiveUS7855731B2Reasonable priceSimple dataTelevision system detailsPicture signal generatorsDigital videoMotion vector

An image vibration-compensating apparatus and a method thereof are provided. The apparatus and the method are applied in an image-capturing apparatus, such as a digital still camera (DSC) or digital video recorder (DVR), for compensating image vibration when capturing an image. The image vibration-compensating apparatus comprises an adaptive edge extractor, a sub-region movement detector, a frame motion calculator, and a correcting vector generator. The image vibration-compensating apparatus analyses the difference between the current image and the previous image, and outputs the correcting motion vector to achieve the function of image vibration-compensation. In the image vibration-compensating method, an accumulate compensation mode is used to prevent fast motion of an image frame which will cause discomfort of the user's eyes when a relatively large image vibration occurs in a short period.

Owner:NOVATEK MICROELECTRONICS CORP

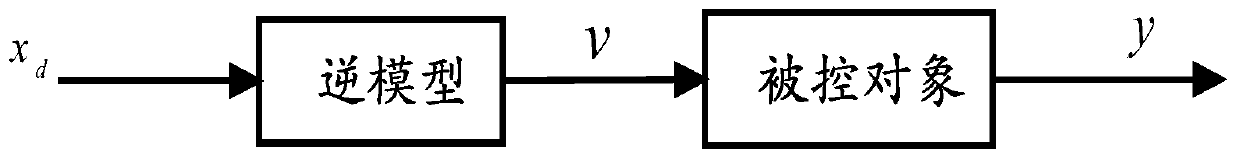

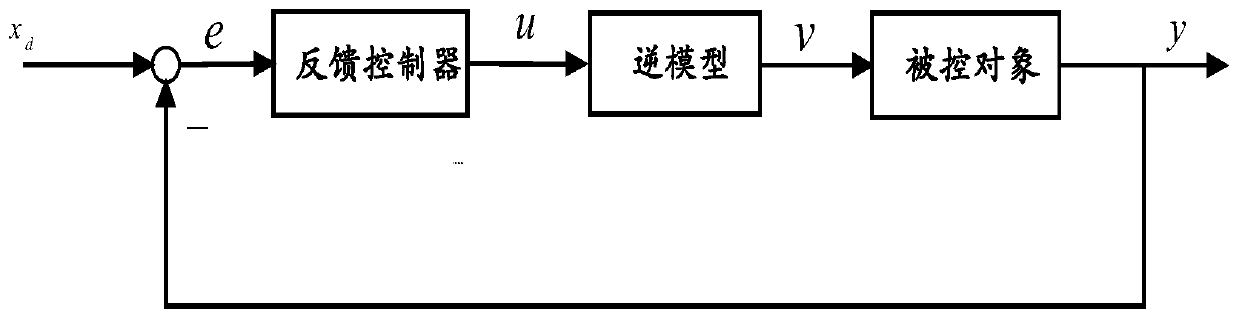

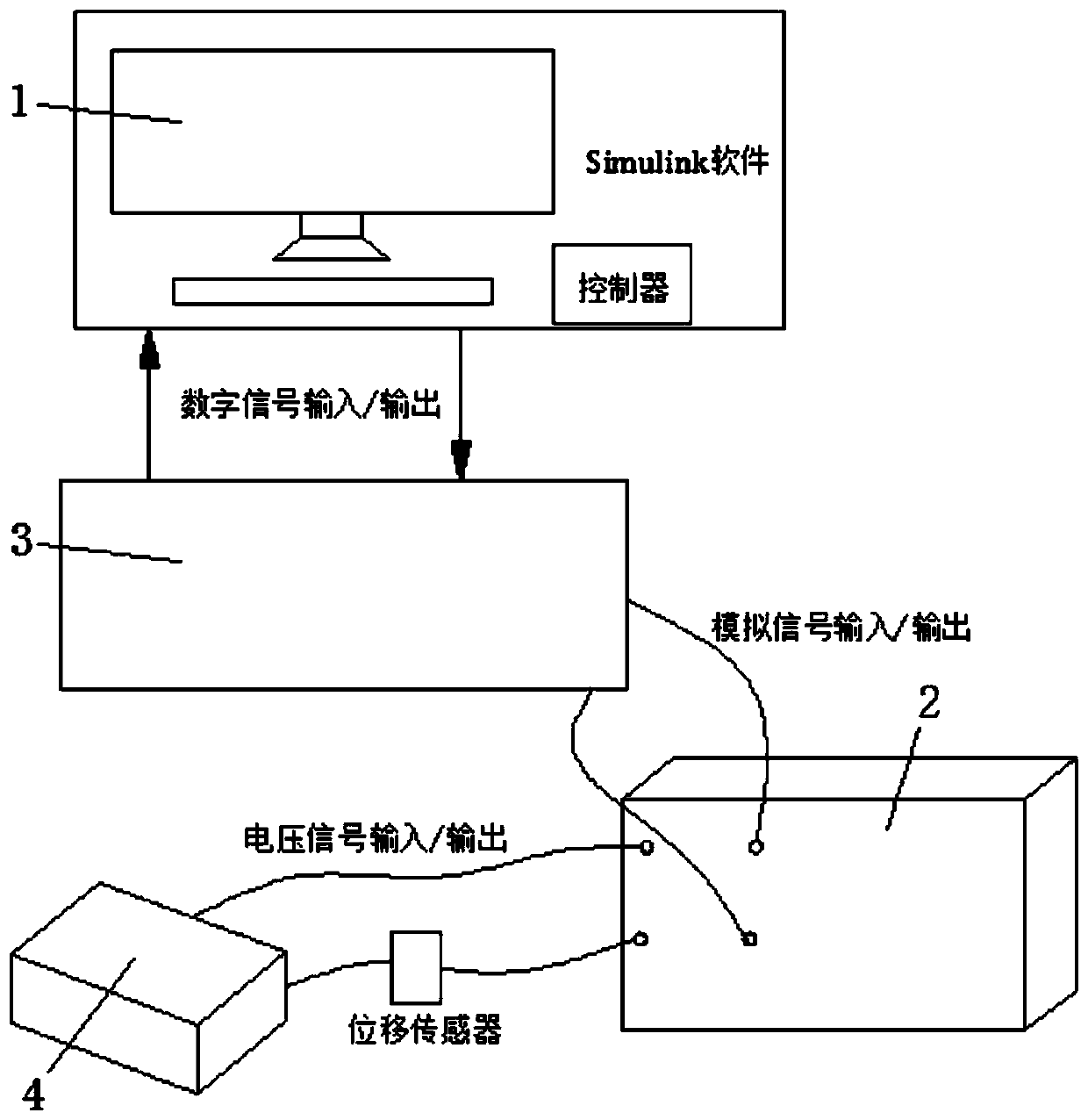

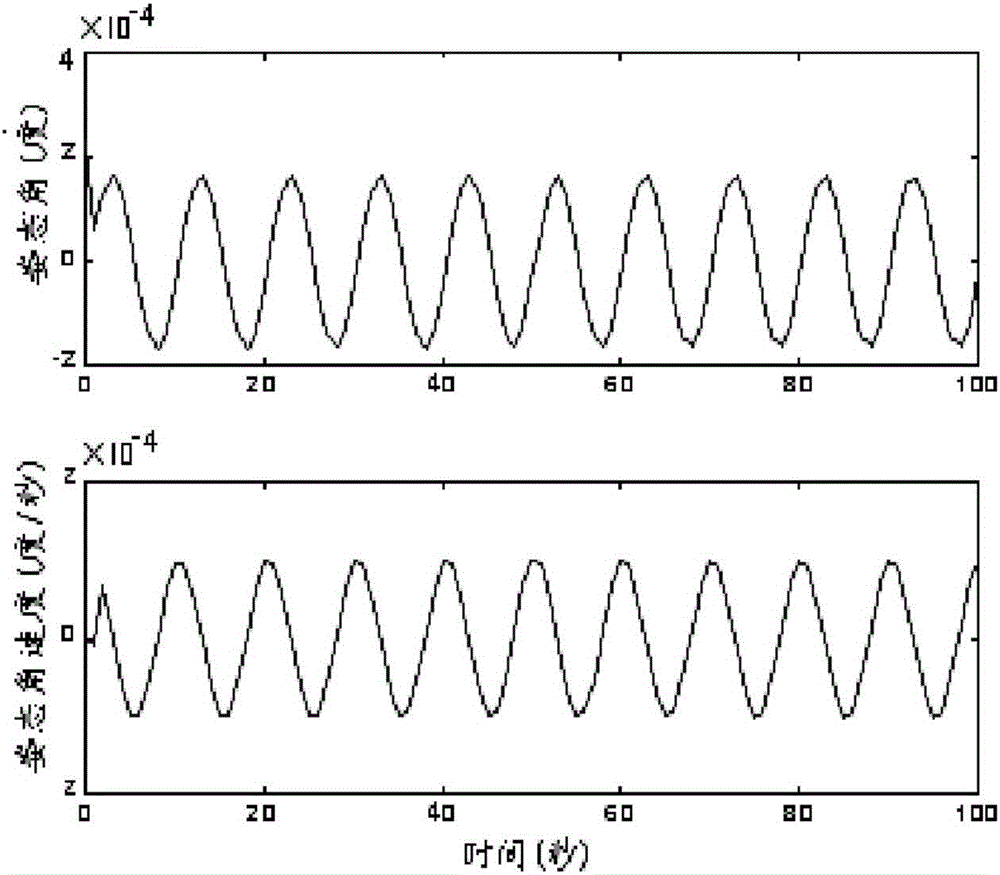

Micro-positioning platform based on piezoelectric ceramic driving and modeling and control method thereof

PendingCN111142404AFew unknown parametersReduce the difficulty of selectionSimulator controlDynamic modelsControl manner

The invention belongs to the technical field of micro-positioning platforms. The invention discloses a micro-positioning platform based on piezoelectric ceramic driving and a modeling and control method thereof. The micro-positioning platform comprises a hardware part and a software part, the software part comprises Simulink software loaded in an industrial personal computer, and communication connection between the industrial personal computer and a data collection card is realized based on the software part to form closed-loop deviation control; the modeling method adopts a Hammerstein modelas a modeling basis, and comprises a static nonlinear part and a linear dynamic part: constructing a static nonlinear function based on a Boc-Wen model, and identifying unknown parameters of the model by adopting a particle swarm algorithm; a linear dynamic model is constructed, the model is equivalent to a linear second-order time-invariant system, and a Matlab recognition toolbox is adopted inthe model to obtain parameters; according to the control method, a composite control mode of feedforward control and feedback control is adopted; in conclusion, the high-precision positioning device has a high-precision positioning effect.

Owner:JILIN UNIV

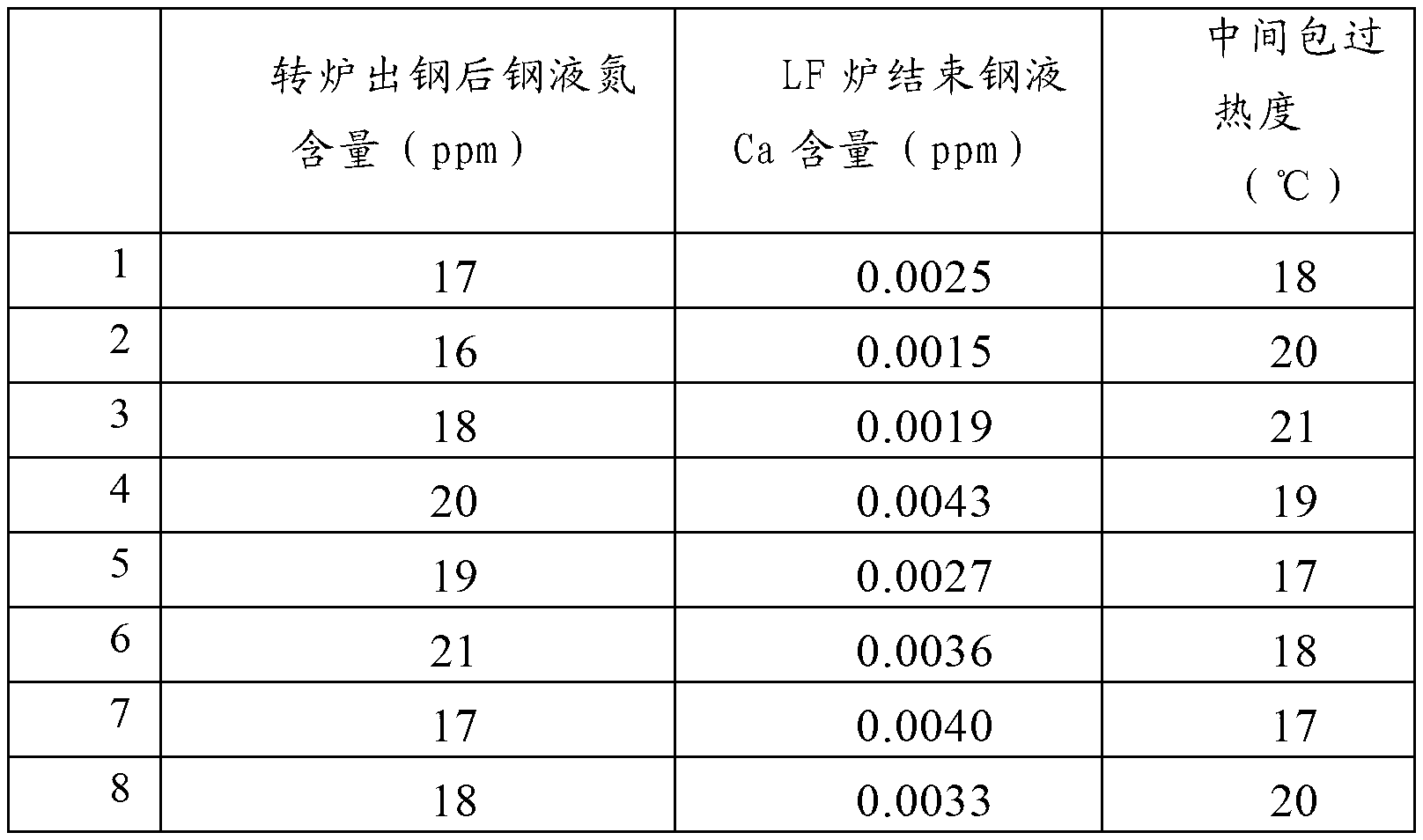

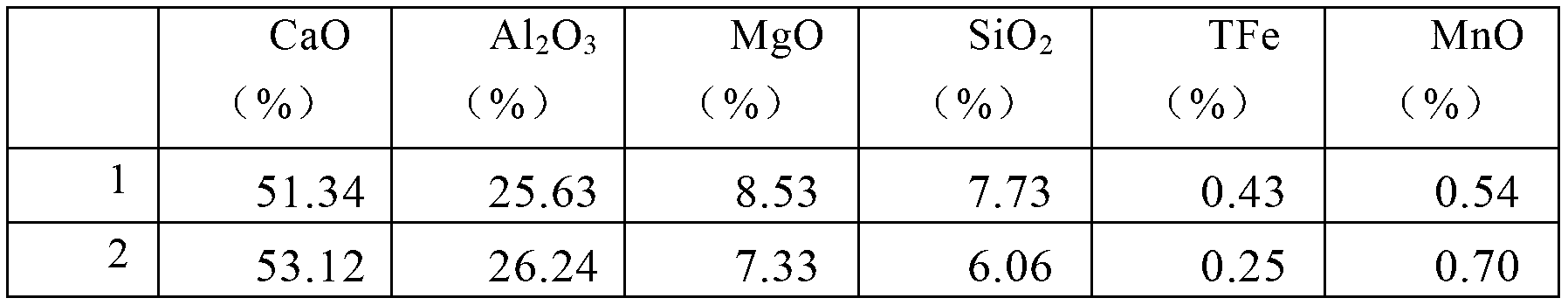

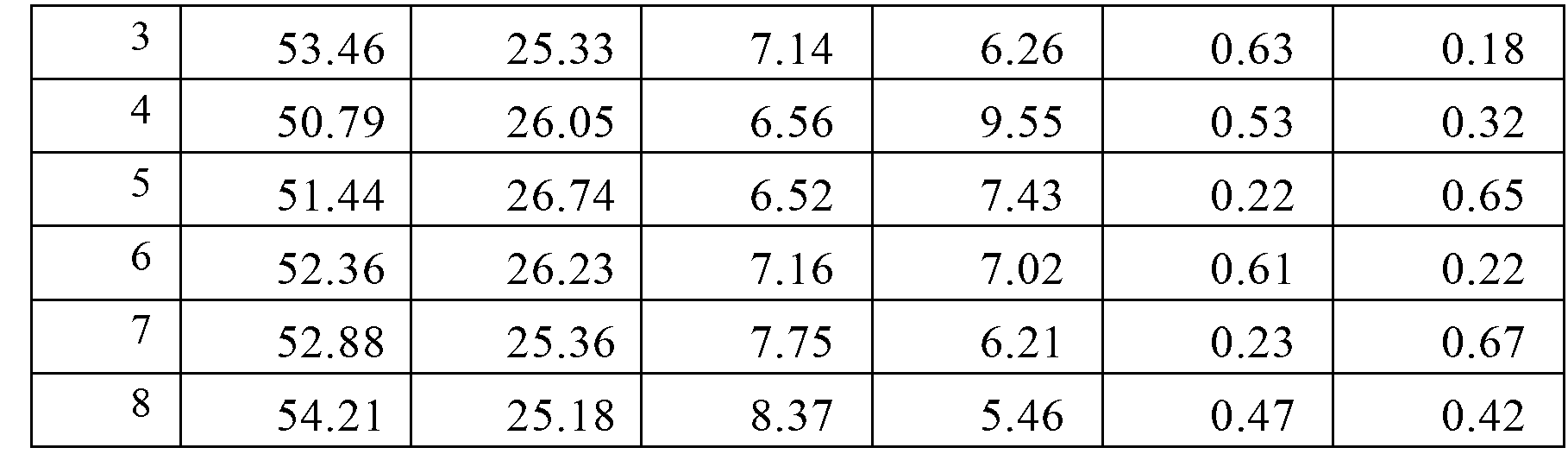

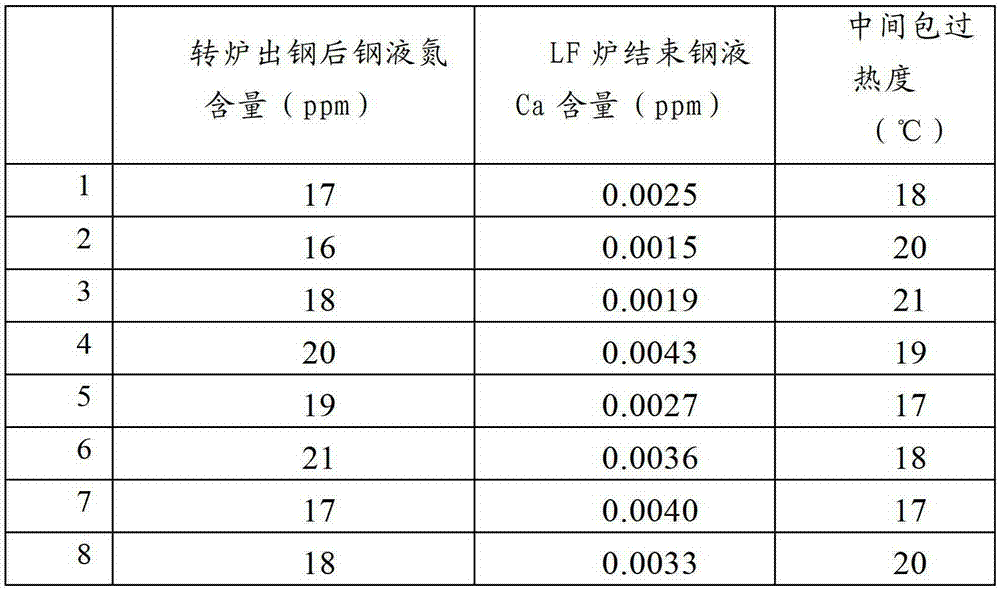

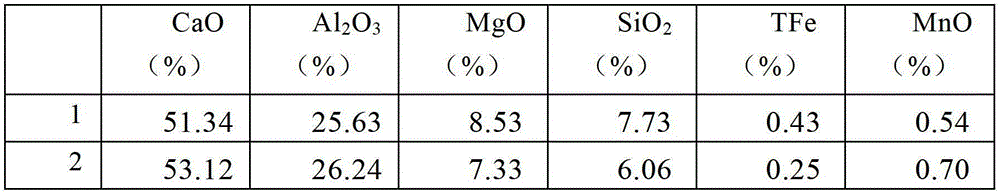

Method for improving cleanness of Nb-Ti containing steel

The invention provides a method for improving cleanness of Nb-Ti containing steel. The method comprises the following steps of: smelting in a top-bottom combined blowing converter under the condition of argon gas bottom-blowing in the whole process; adding small-grain limes and fluorite in a steel tapping process; adding slow-release deoxidizing agent to the top of the slag after the steel tapping; carrying out secondary refining onto molten steel; feeding the refined molten steel to a continuous casting process for carrying out full-protection casting. According to the invention, low-nitrogen molten steel is obtained by adopting an argon gas bottom-blowing mode in the whole converter smelting process, calcium treatment and soft blowing are performed after LF (Low Frequency) furnace refining desulfuration and heating up, Nb-Ti alloying is carried out and the alloy melting is promoted by carrying out soft blowing again. Moreover, oxide impurities can be reduced by calcium pre-treatment and a soft-blowing process, the Nb-Ti alloy is promoted to melt by the soft blowing, impurities are removed by RH (Ruhrstahl Heraeus) vacuum refining and degassing, impurities are further removed by carrying out soft blowing after breaking the vacuum, and casting blank segregation can be weakened by continuous casting and low-superheat-degree casting, so that the purpose of controlling the oxide impurities and the nitride impurities in the steel is achieved.

Owner:SHOUGANG CORPORATION

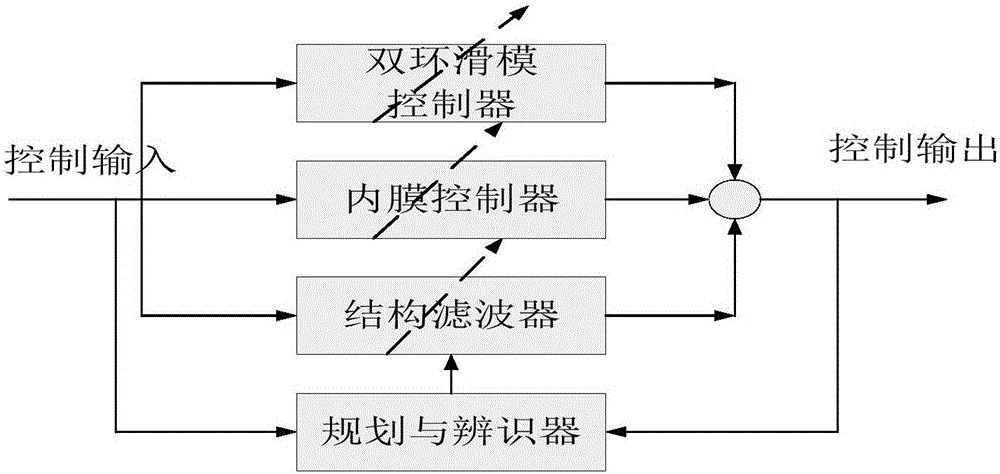

Self-adaption low-order controller for unmanned helicopter

ActiveCN106842953AEasy to handle control constraints and state constraintsAchieve stability controlAdaptive controlSelf adaptivePID controller

Owner:杭州睿杰智能空中机器人科技有限公司

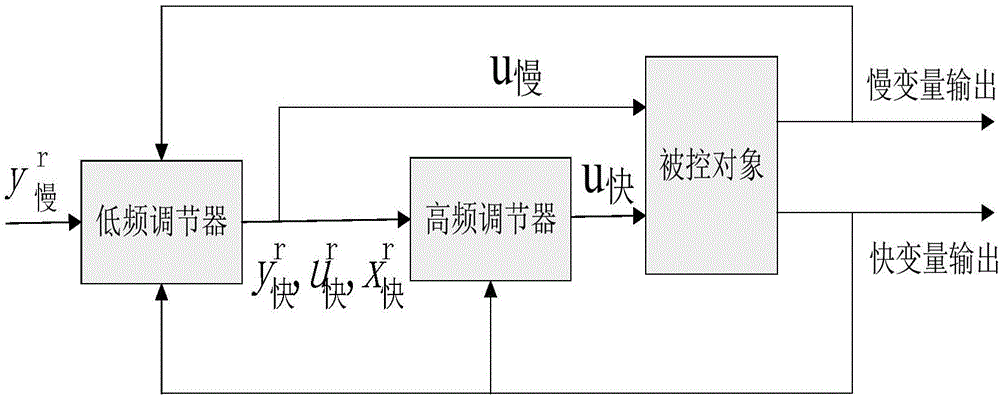

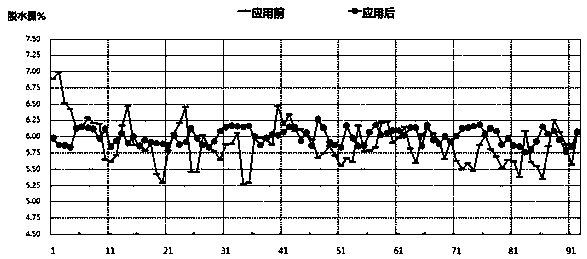

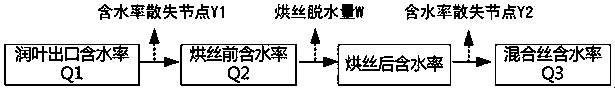

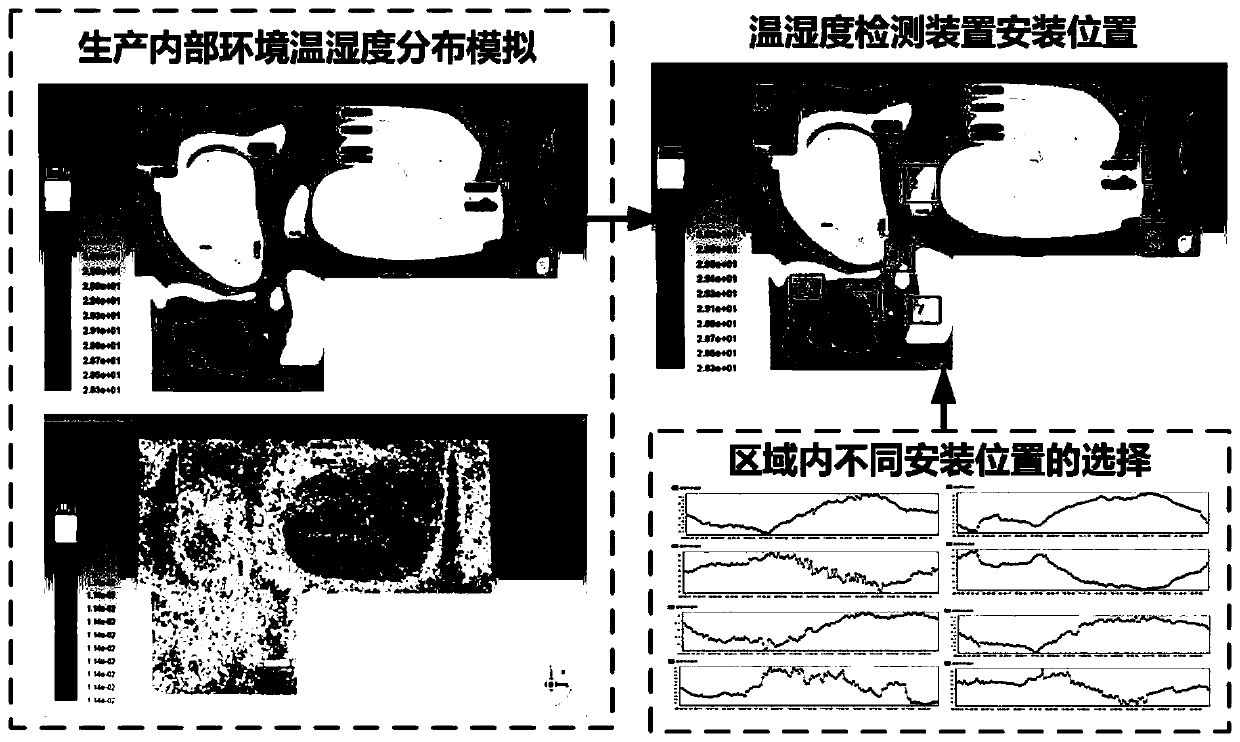

Method and system for stabilizing processing strength of drum-type cut-tobacco dryer

ActiveCN110973680AAchieve stability controlStable batch-to-batch processing strengthTobacco preparationPrediction systemProcess engineering

The invention discloses a method and a system for stabilizing the processing strength of a drum-type cut tobacco dryer. The invention discloses the method and system for stabilizing the processing strength of a drum-type cut-tobacco dryer, which belong to the technical field of tobacco control, and comprise the following steps: a mathematical model of the processing strength of the cut-tobacco dryer and moisture loss of cut-tobacco processing is established, and a dynamic prediction system of the processing strength of the cut-tobacco dryer is established based on the mathematical model; before production procedures of tobacco leaf moistening and feeding, the processing strength dynamic prediction system automatically predicts moisture loss of each subsequent procedure section according tothe mathematical model, adjusts and sets moisture at an outlet of the tobacco leaf moistening and processing procedure, and stabilizes the dehydration amount of the cut-tobacco dryer so as to stabilize the processing strength of the cut-tobacco dryer; when a cut tobacco drying process begins, the processing strength dynamic prediction system performs cut tobacco drying outlet moisture correctionaccording to a correction model by collecting the actual value of the cut tobacco drying inlet moisture so as to stabilize the mean value of the batch-to-batch dehydration amount of the cut tobacco drying process, greatly reduce the batch-to-batch fluctuation range of the dehydration amount of the drum-type cut tobacco dryer and stabilize the product processing strength.

Owner:HONGTA TOBACCO GRP

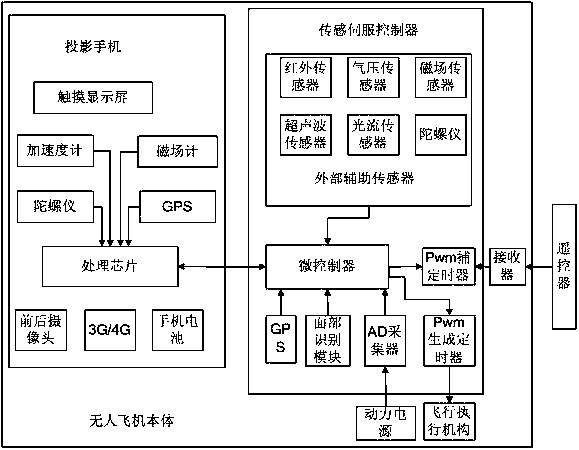

Unmanned aerial vehicle flight control system based on projection mobile phone

InactiveCN108459617AAchieve stability controlEasy to operateAutonomous decision making processPosition/course control in three dimensionsMicrocontrollerUltrasonic sensor

The present invention discloses an unmanned aerial vehicle flight control system based on a projection mobile phone. The system comprises an unmanned aerial vehicle body, and a projection mobile phone, a sensing servo controller and a flight execution mechanism which are fixedly arranged on the unmanned aerial vehicle body and are connected to each other; the projection mobile phone is internallyprovided with a flight control program; the projection mobile phone is internally provided with a gyroscope, an accelerometer, a GPS and a magnetic field sensor; the sensing servo controller is internally provided with a microcontroller, an intelligent identification module, a GPS, a timer, an AD sampler, an infrared sensor, an air pressure sensor, an ultrasonic sensor, a light stream sensor, a magnetic field sensor, an external assistant sensor of the gyroscope; and the sensing servo controller is internally provided with a PWM generation timer connected with the flight execution mechanism. The unmanned aerial vehicle flight control system achieves saving of system resources, improvement of stability and easy control.

Owner:SHENZHEN LEVETOP TECH CO LTD

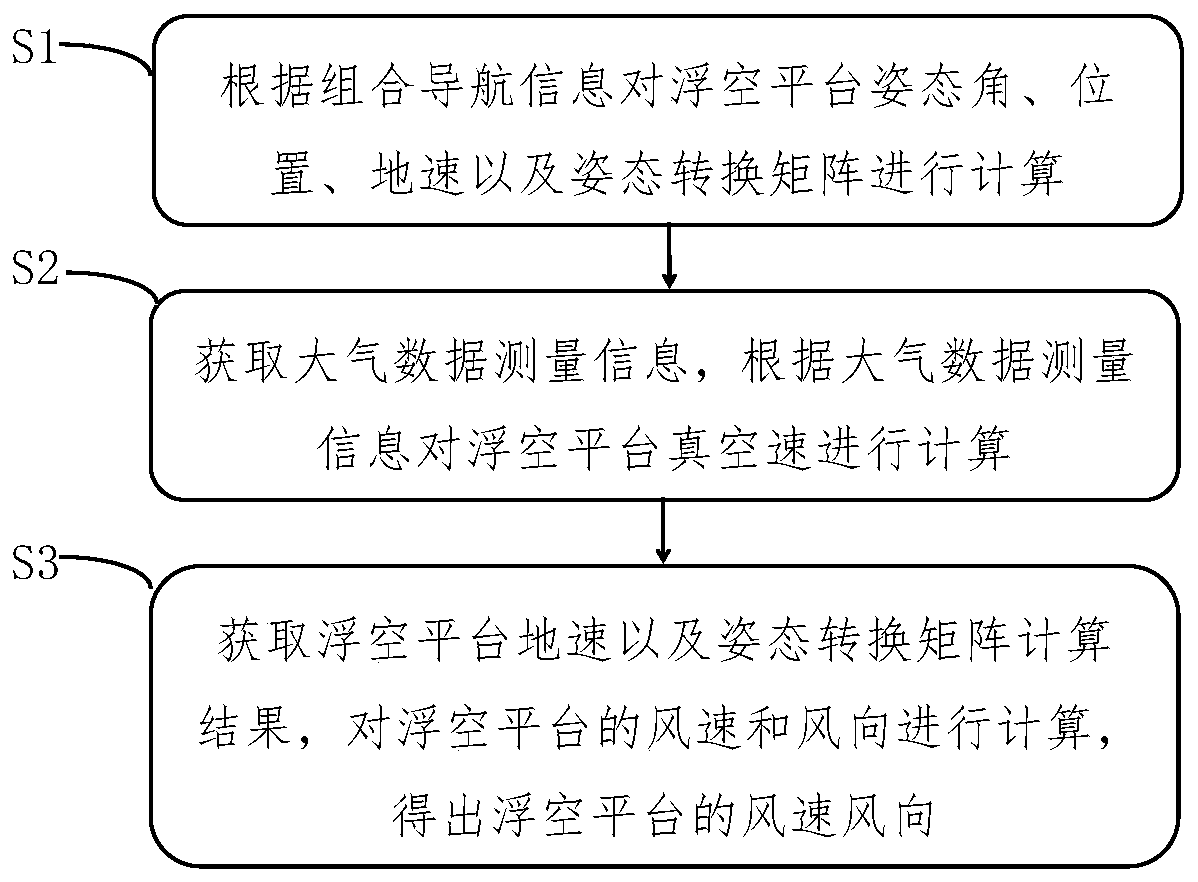

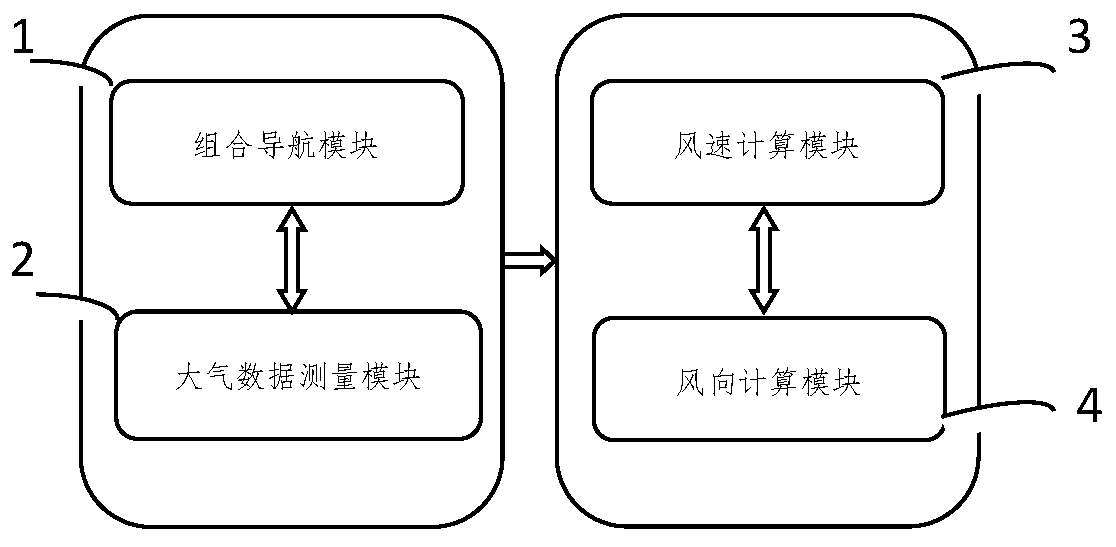

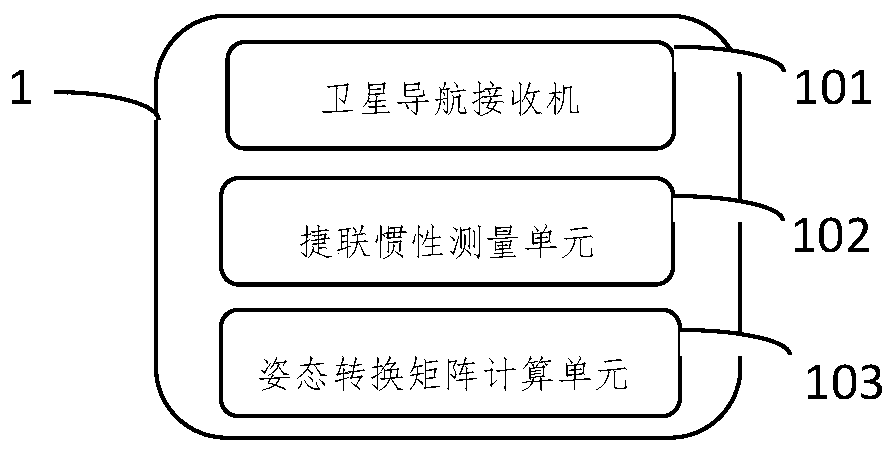

Wind speed and wind direction measurement method and device based on floating platform

InactiveCN109781138AImprove wind resistanceLow costIndication/recording movementNavigation instrumentsEngineeringFloating platform

The invention relates to the field of wind speed and wind direction measurement, in particular to a wind speed and wind direction measurement method and device based on a floating platform, and the method comprises the steps: obtaining integrated navigation information, and calculating the ground speed and attitude conversion matrix of the floating platform according to the integrated navigation information; acquiring atmospheric data measurement information, and calculating the vacuum speed of the floating platform according to the atmospheric data measurement information; and obtaining a ground speed and attitude conversion matrix of the floating platform and a vacuum speed calculation result, and calculating the wind speed and wind direction of the floating platform to obtain the wind speed and wind direction of the floating platform. The technical scheme is convenient and flexible to use, the problem that a common wind measurement method is not suitable for large-area continuous real-time wind speed and wind direction measurement is solved, the wind resistance of the floating platform is improved, and stable control over the platform is achieved.

Owner:BEIJING INST OF ELECTRONICS SYST ENG

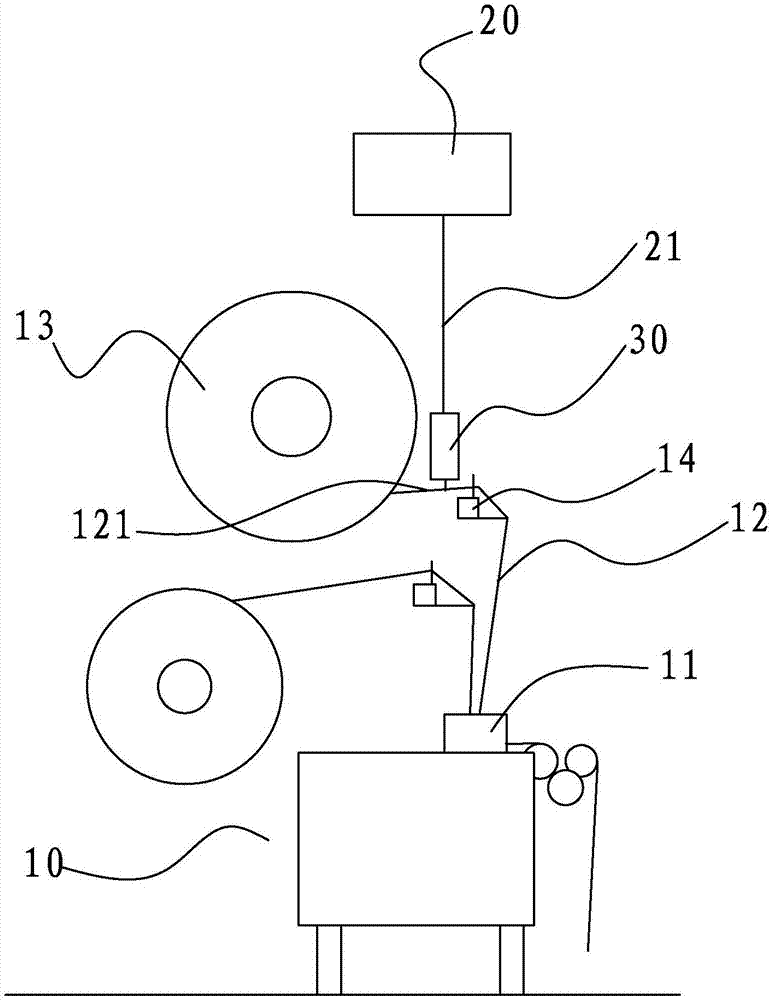

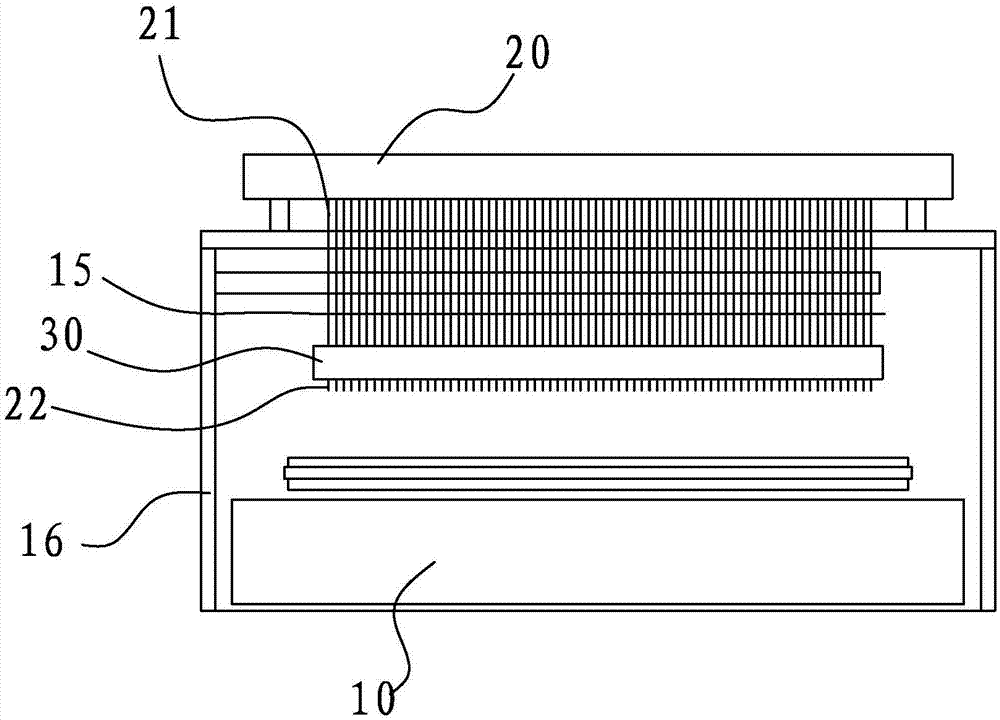

High-speed jacquard warp knitter

PendingCN106995976AAchieve stability controlImprove jacquard qualityFlat warp knitting machinesEngineeringWarp knitting

The invention relates to a high-speed jacquard warp knitter, comprising a warp knitting device and a jacquard mechanism arranged above the warp knitting device. The jacquard mechanism comprises a jacquard thread, a jacquard needle and a jacquard thread transmission mechanism, the upper end of the jacquard thread is connected to the jacquard thread transmission mechanism, the lower end of the jacquard thread is connected to the jacquard needle, the jacquard needle corresponds to a warp of the warp knitting device, the high-speed jacquard warp knitter also comprises a guide mechanism, the guide mechanism comprises a first guide plate, a second guide plate, a guide rod and a mounting block, vertical movement of the jacquard needle is guided through the first guide plate, the second guide plate, the guide rod and the mounting block such that the vertical movement of the jacquard needle is protected from disturbance by jacquard thread skewing, the warp can be operated better, warp tension is stably controlled, and jacquard quality of warp knit is improved. The high-speed jacquard warp knitter has the advantage of simple structure and is suitable particularly for a jacquard warp knitter requiring multiple jacquard needles.

Owner:FUJIAN KBOXING WARPKNITTING

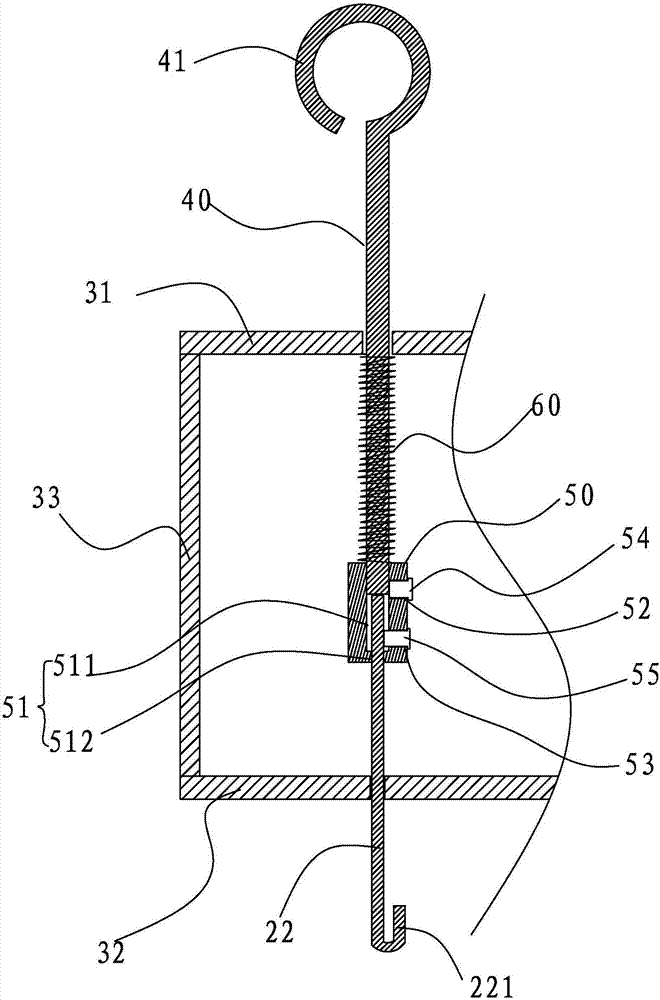

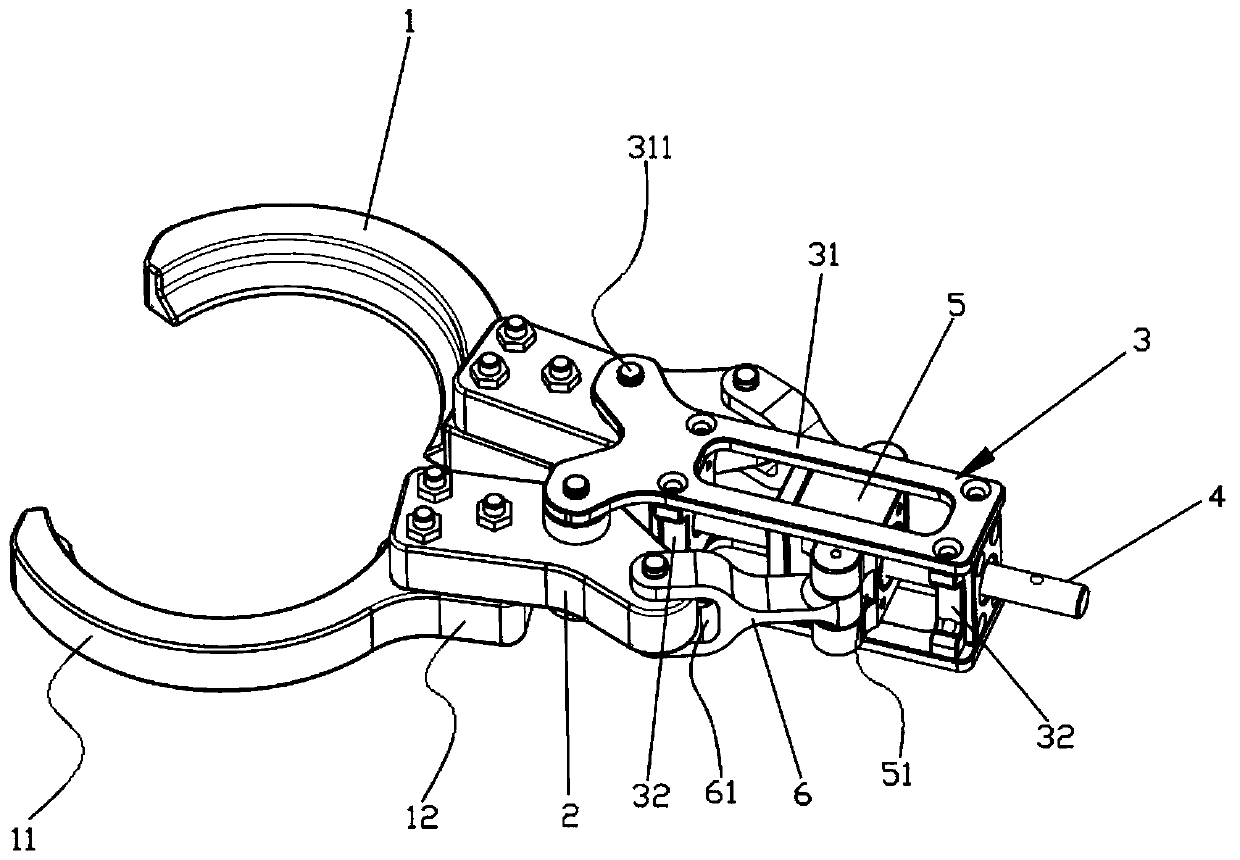

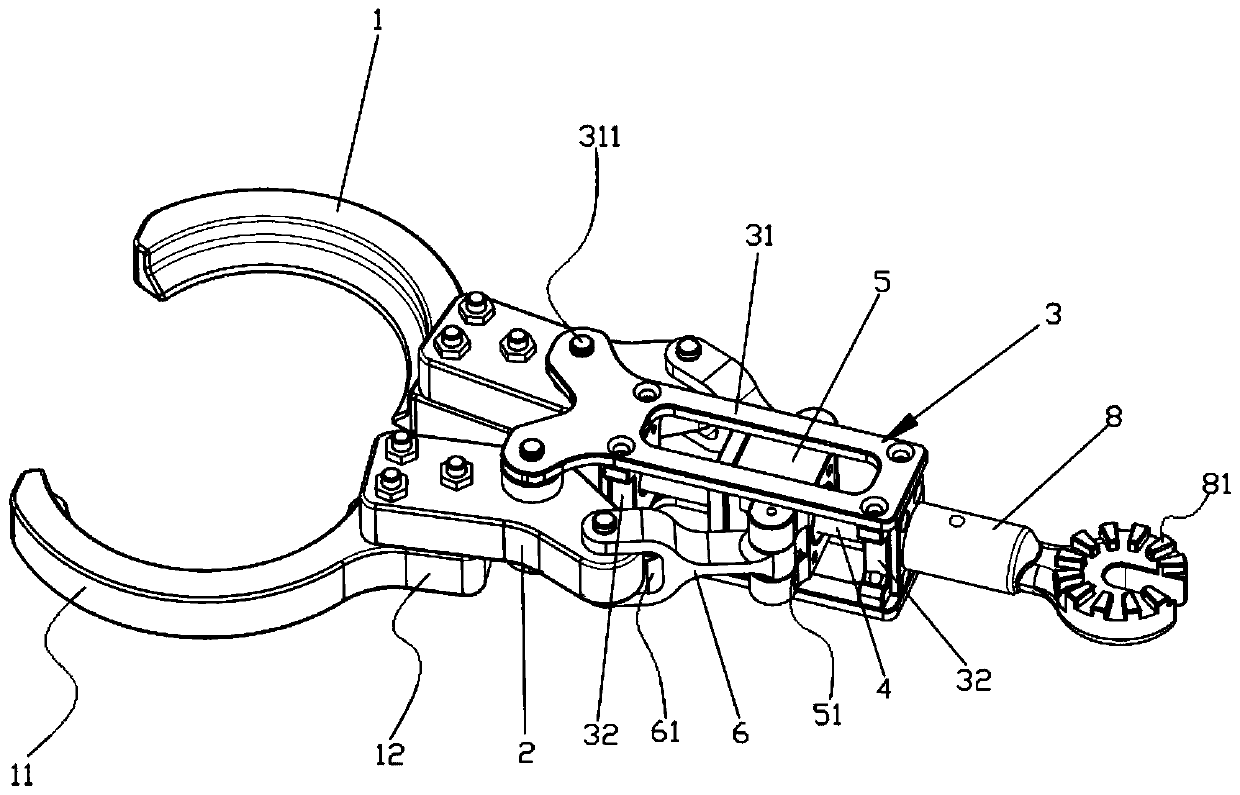

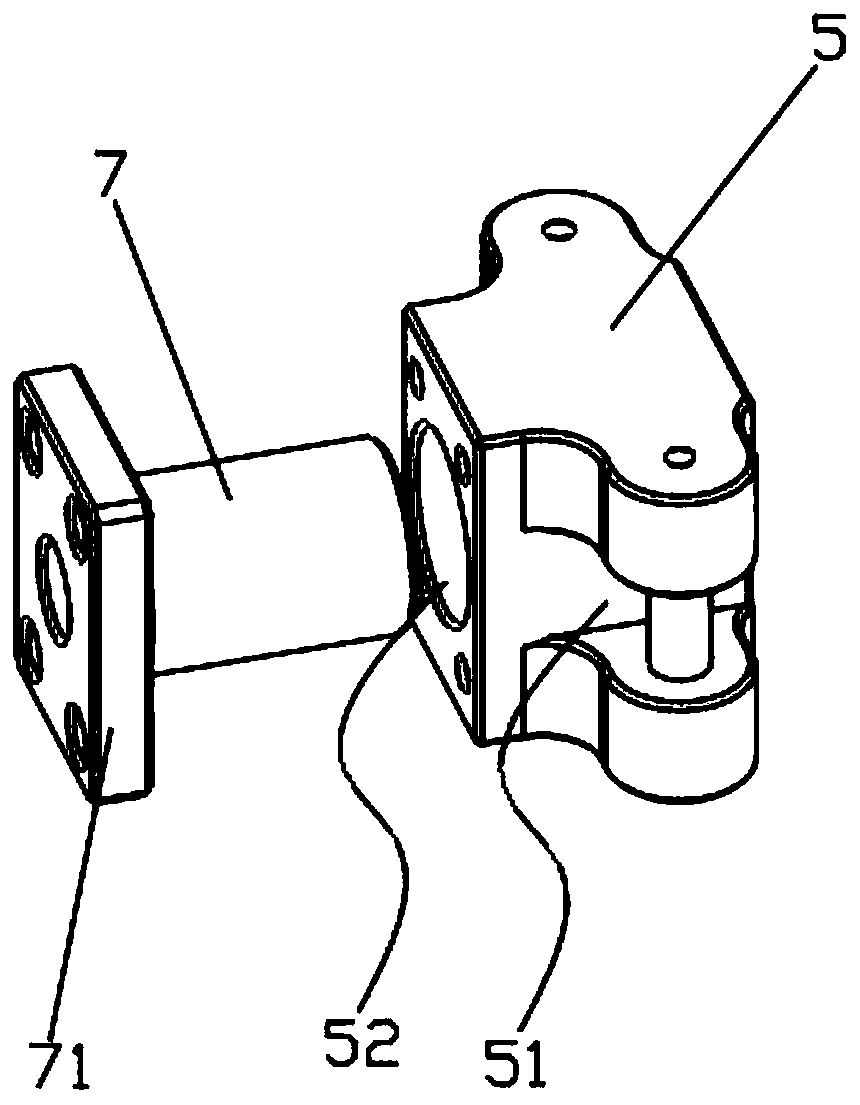

Insulator clamping jaw

PendingCN111162475AAchieve stability controlEasy to operateApparatus for overhead lines/cablesEngineeringStructural engineering

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

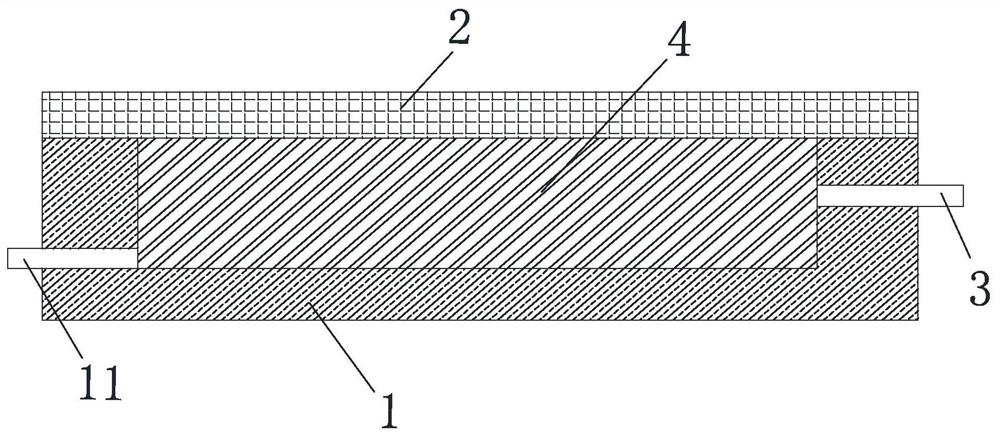

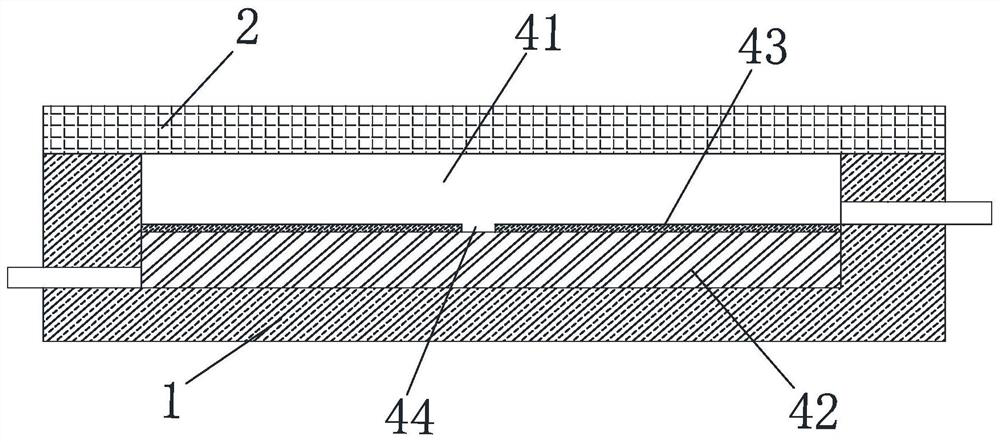

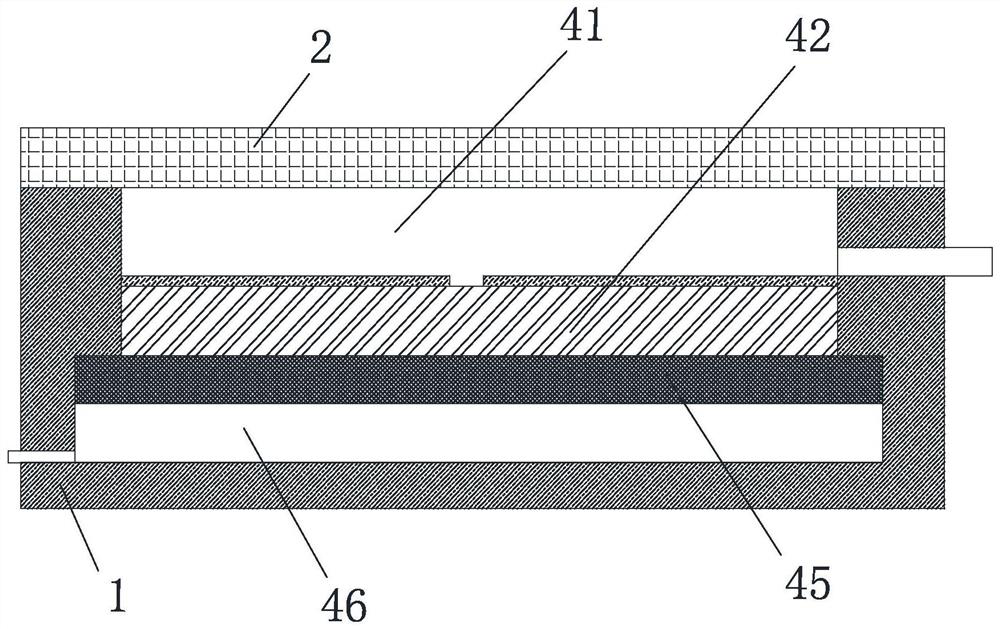

Liquid metal antenna and control system and method thereof

PendingCN113629386AReduce residual rateAchieve stability controlRadiating elements structural formsRadiating element housingsPhysicsMechanical engineering

The invention provides a liquid metal antenna and a control system and method thereof. The liquid metal antenna comprises an antenna body, the antenna body comprises a substrate, a first elastic layer and a feed port, the first elastic layer is fixedly installed on the substrate, a filling cavity is formed between the first elastic layer and the substrate, one end of the feed port is communicated with the filling cavity, the lower part of the substrate is provided with a discharge structure, and one end of the discharge structure is communicated with the filling cavity. Through large-scale deformation of the first elastic layer, the first elastic layer can be attached to the wall surface and the corner of the filling cavity, so that the liquid metal in the filling cavity can be completely discharged, the residual rate of the liquid metal is reduced, an acidic or alkaline solution does not need to be used, stable control of the antenna is realized, and the antenna can work stably.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

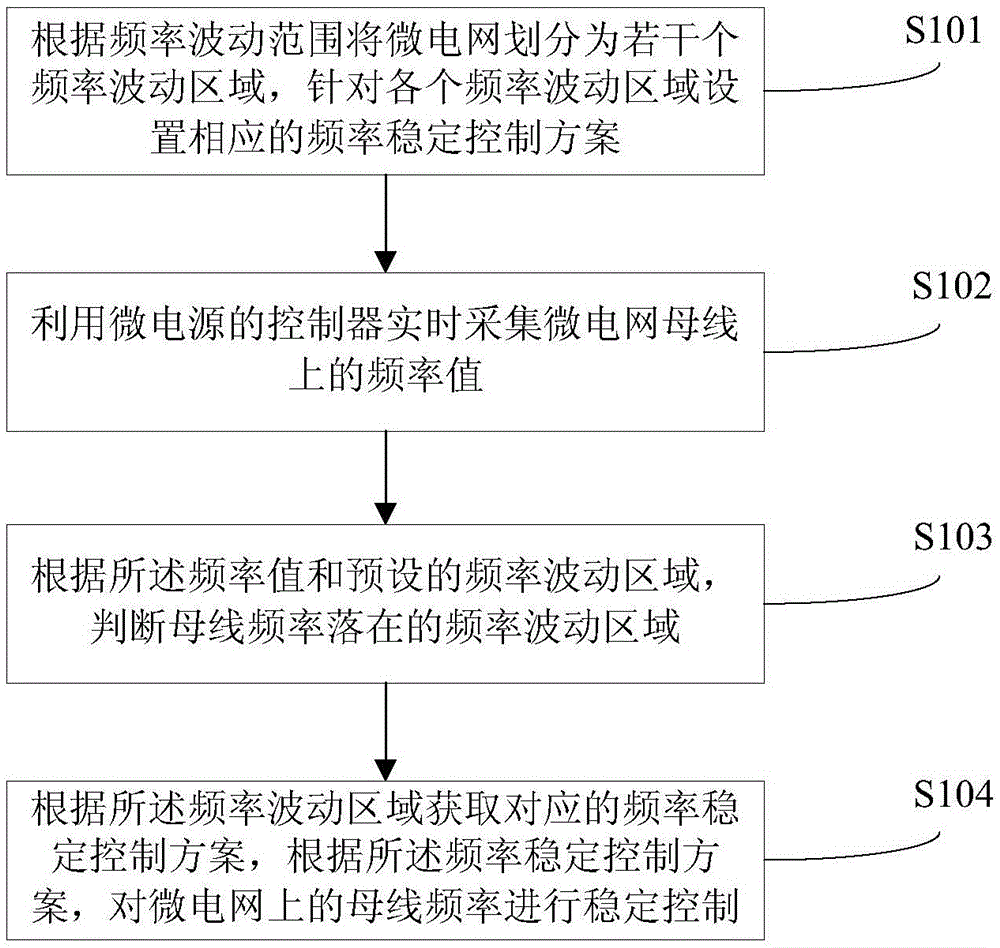

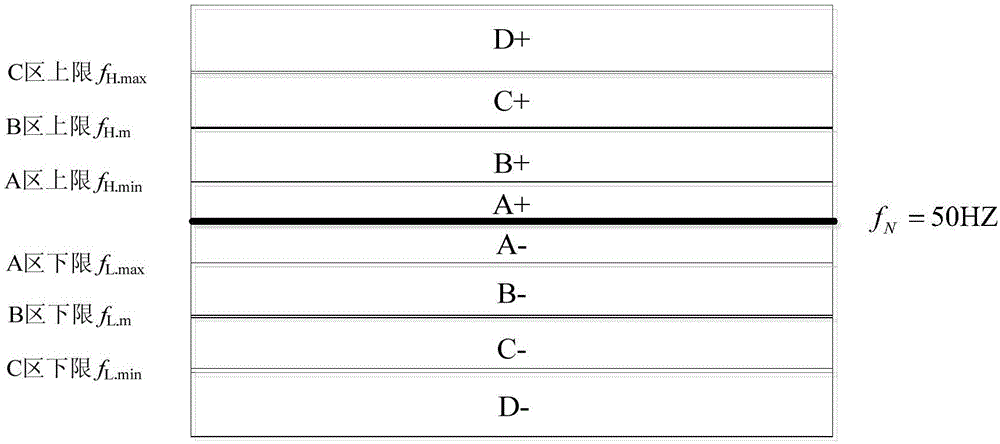

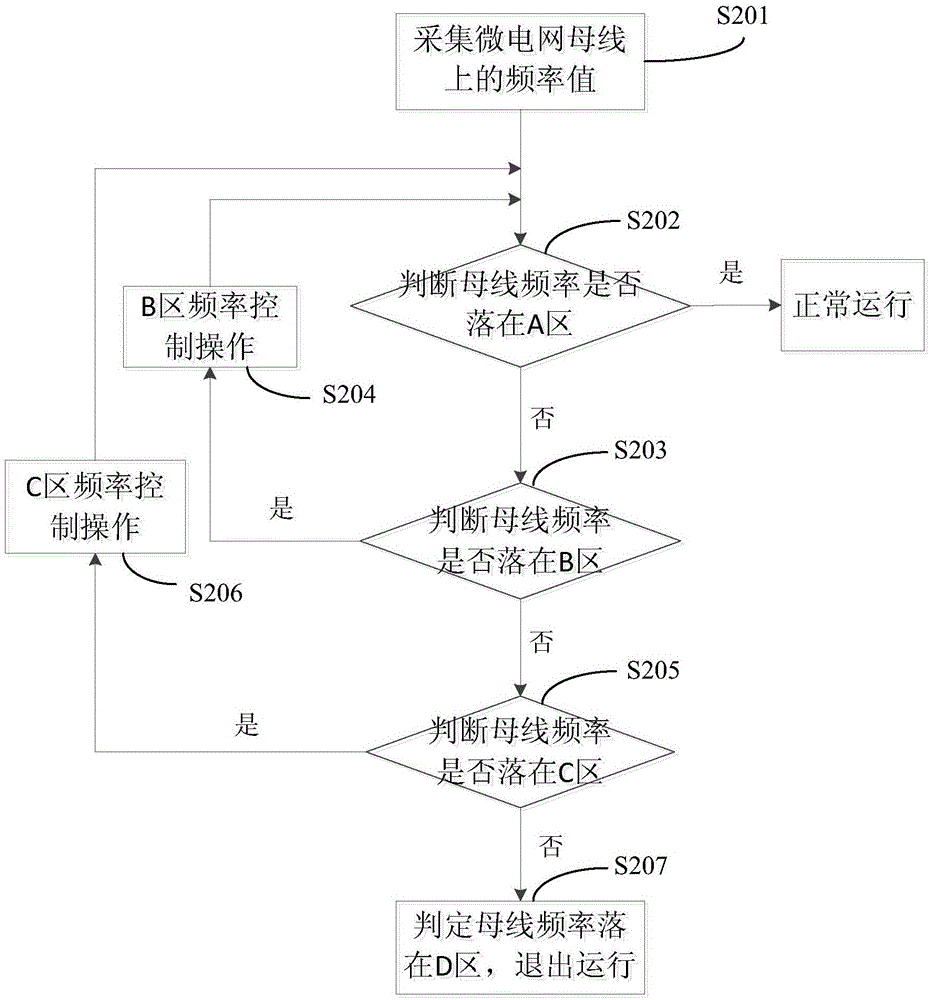

Stable frequency control method and system of microgrid

InactiveCN105071441AAchieve stability controlStable frequency fluctuationSingle network parallel feeding arrangementsAc network load balancingPower gridEngineering

The invention relates to a stable frequency control method and system of a microgrid. The method comprises: a controller of a micro source collects a frequency value of a bus of a microgrid in real time; according to the frequency value and a preset frequency fluctuation zone, a frequency fluctuation zone where a bus frequency is located is determined; on the basis of the frequency fluctuation zone, a corresponding stable frequency control scheme is obtained; and the bus frequency of the microgrid is controlled stably based on the stable frequency control scheme. According to the method and system, the frequency value of the bus of the microgrid is collected in real time by the controller of the micro source and the a frequency fluctuation zone where the bus frequency is located is determined based on the frequency value and the preset frequency fluctuation zone; and according to the determination result and preset control schemes of different frequency fluctuation zones, coordinated control of the micro source, the energy storage system, and the load is realized, so that the fluctuated frequency can be restored rapidly for stability. And thus stable control of frequency fluctuation of the microgrid at different ranges can be realized.

Owner:CHINA SOUTH POWER GRID ELECTRIC POWER RES INST +3

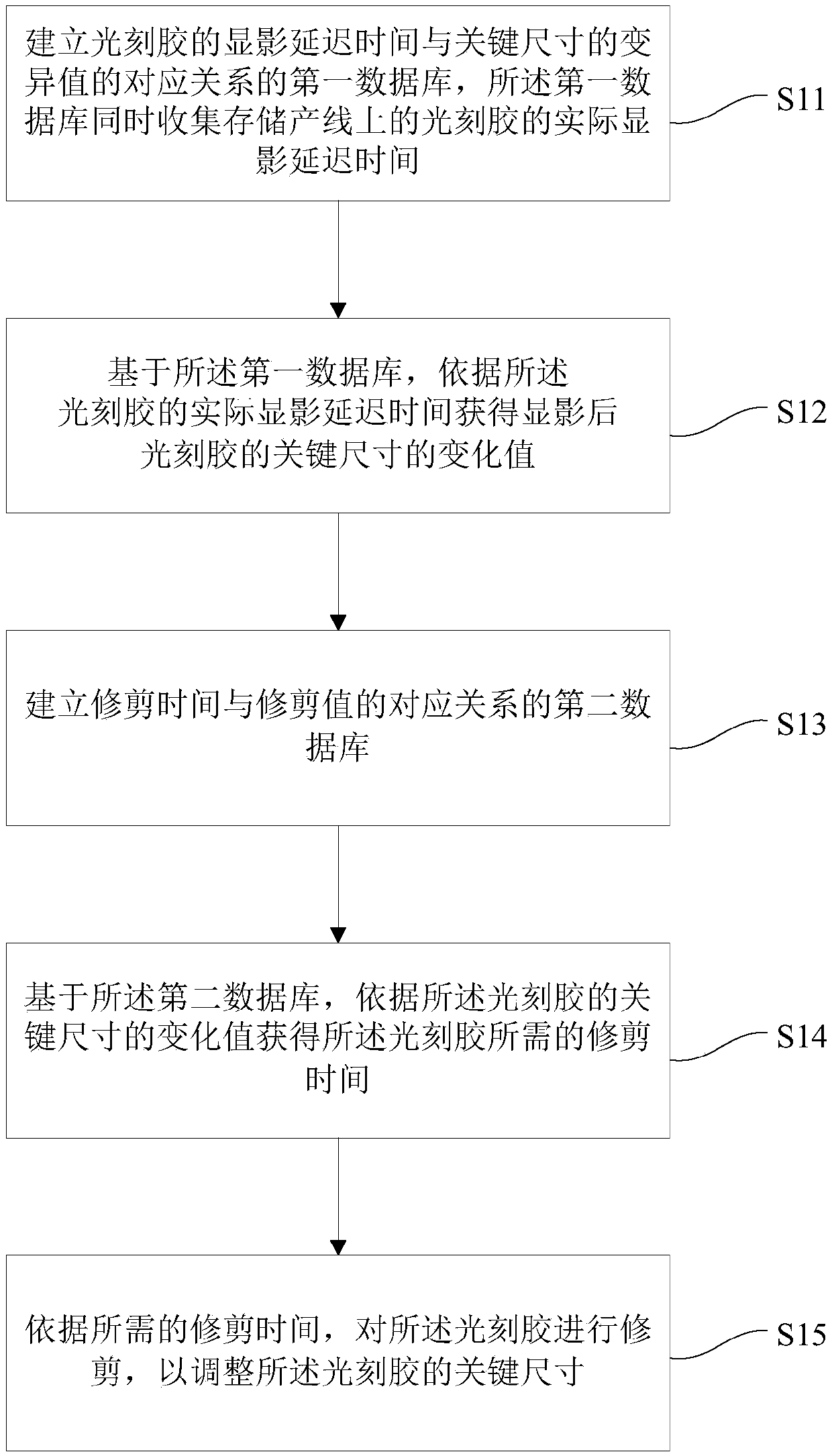

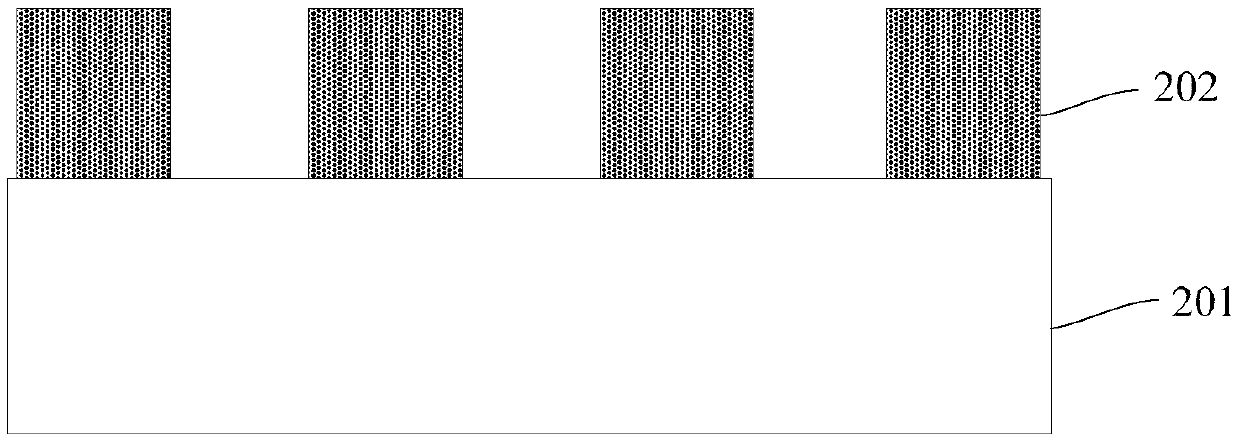

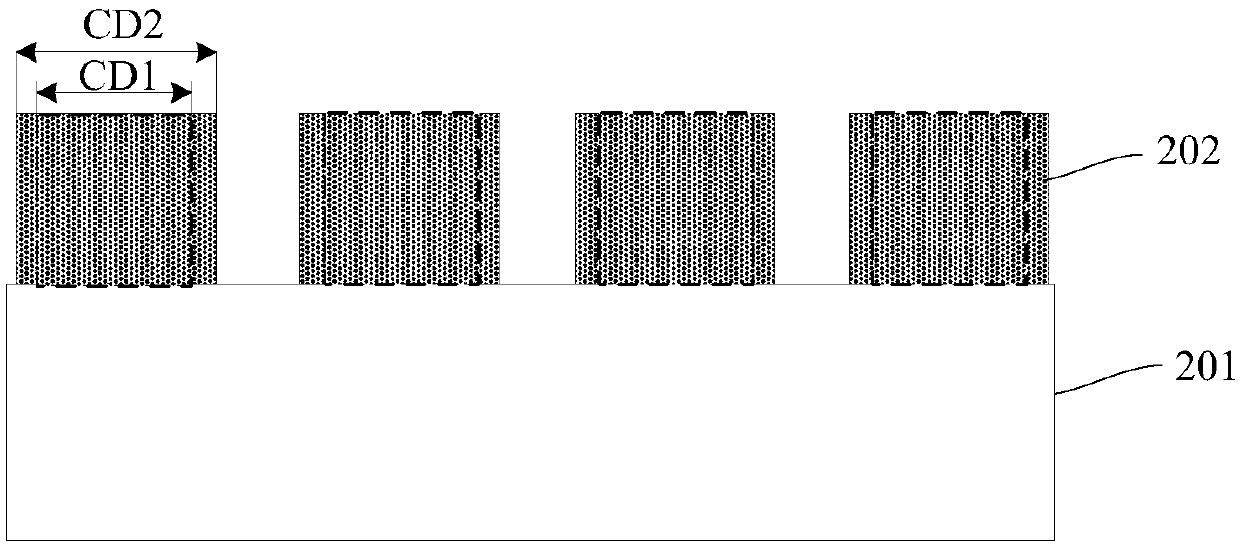

Critical dimension control method and control system

PendingCN110928149AAchieve stability controlSolve the problem that the key size becomes largerPhotosensitive material processingProduction lineAlgorithm

The invention provides a critical dimension control method and control system, and the control system comprises a first database which is used for providing the corresponding relation between the development delay time of photoresist and the variation value of the critical dimension, and collecting and storing the actual development delay time of the photoresist on a production line; a variation value calculation unit which is used for obtaining the variation value of the key size of the developed photoresist from the first database according to the actual development delay time; a second database which is used for providing a corresponding relationship between the trimming time and the trimming value; a trimming time calculation unit which is used for obtaining trimming time required by the photoresist from a second database according to the variation value; and a trimming station which is used for trimming the photoresist according to the required trimming time so as to adjust the key size of the photoresist. According to the invention, the variation value of the critical dimension of the photoresist caused by development delay and the required corresponding trimming time can beautomatically calculated, and the trimming station is set to trim the photoresist, so that the stability control of the critical dimension is realized.

Owner:CHANGXIN MEMORY TECH INC

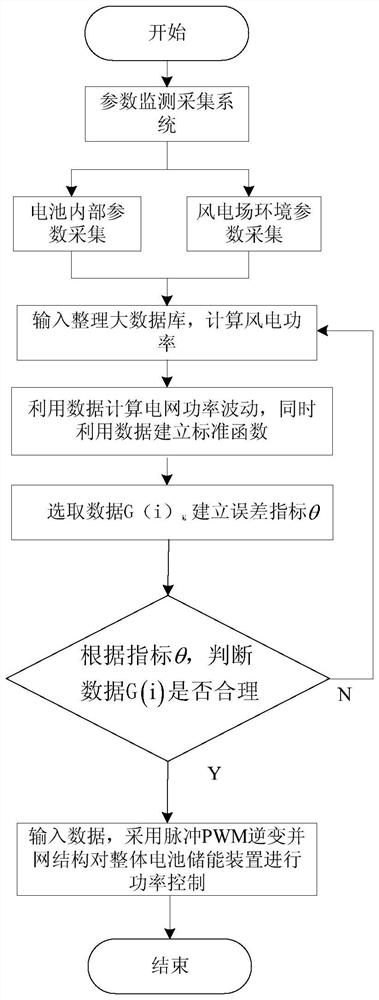

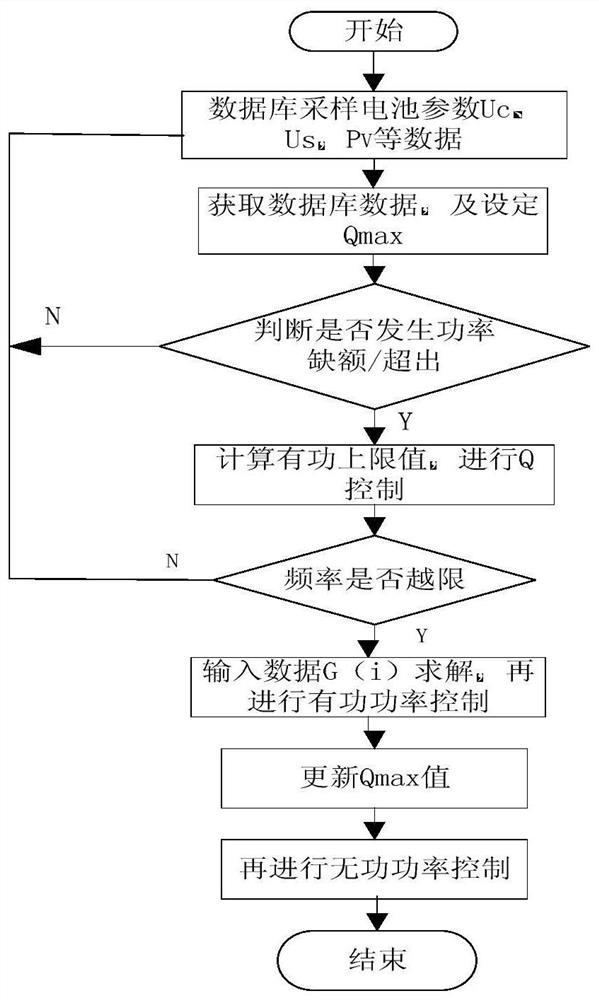

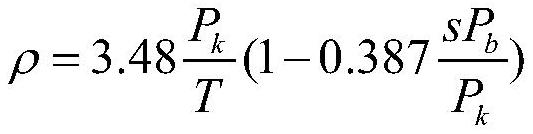

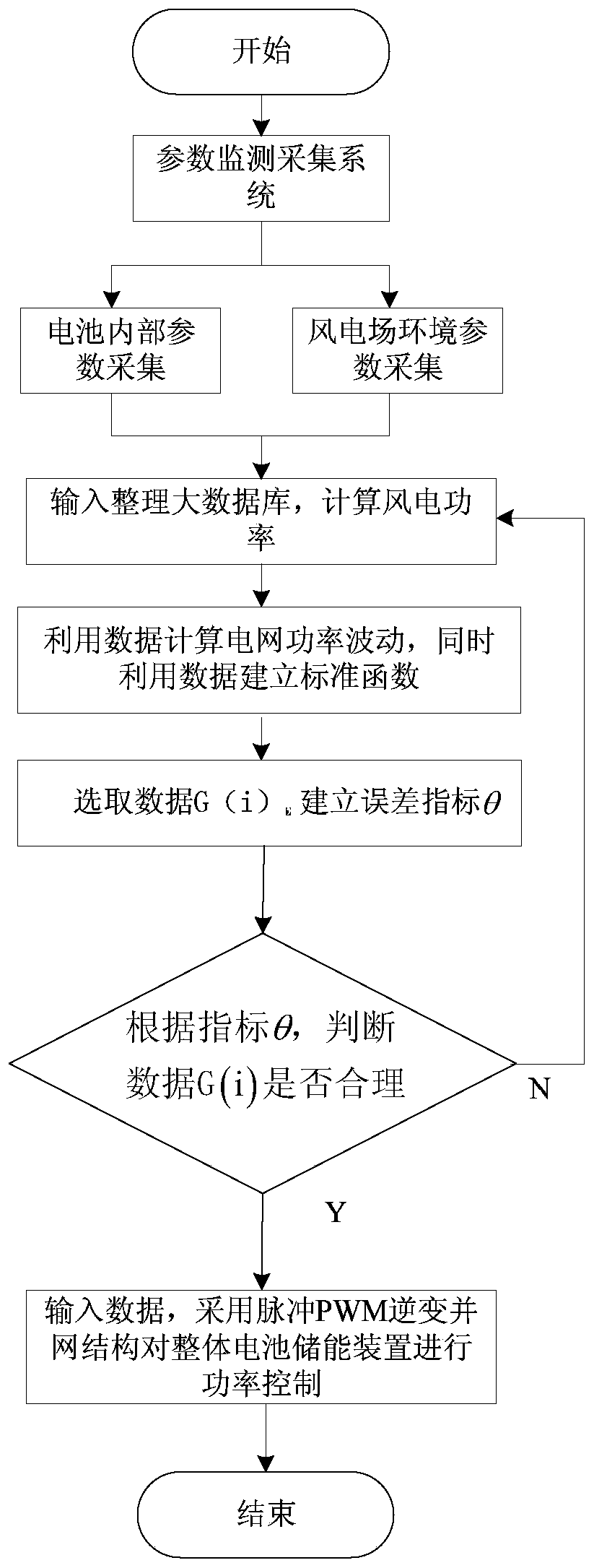

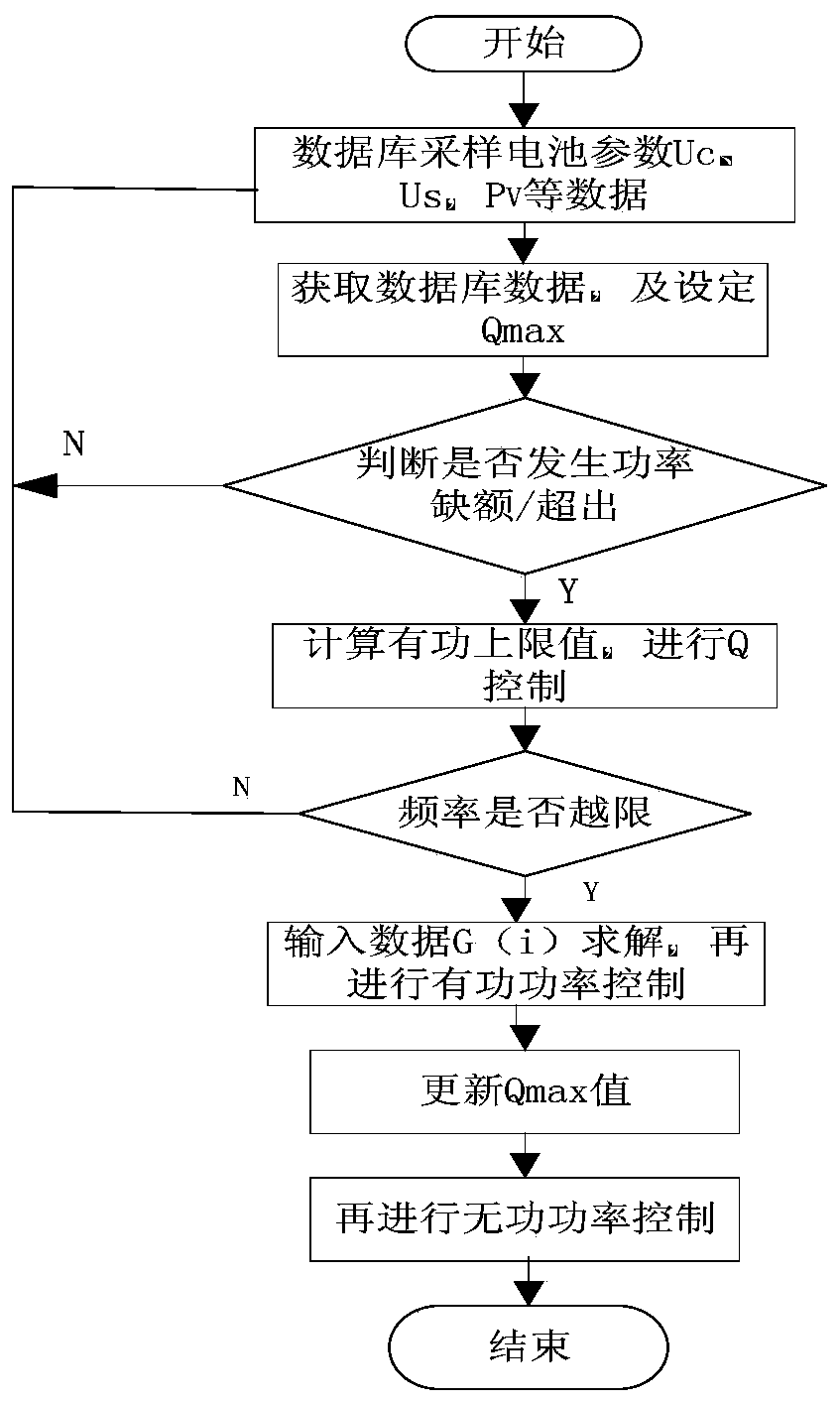

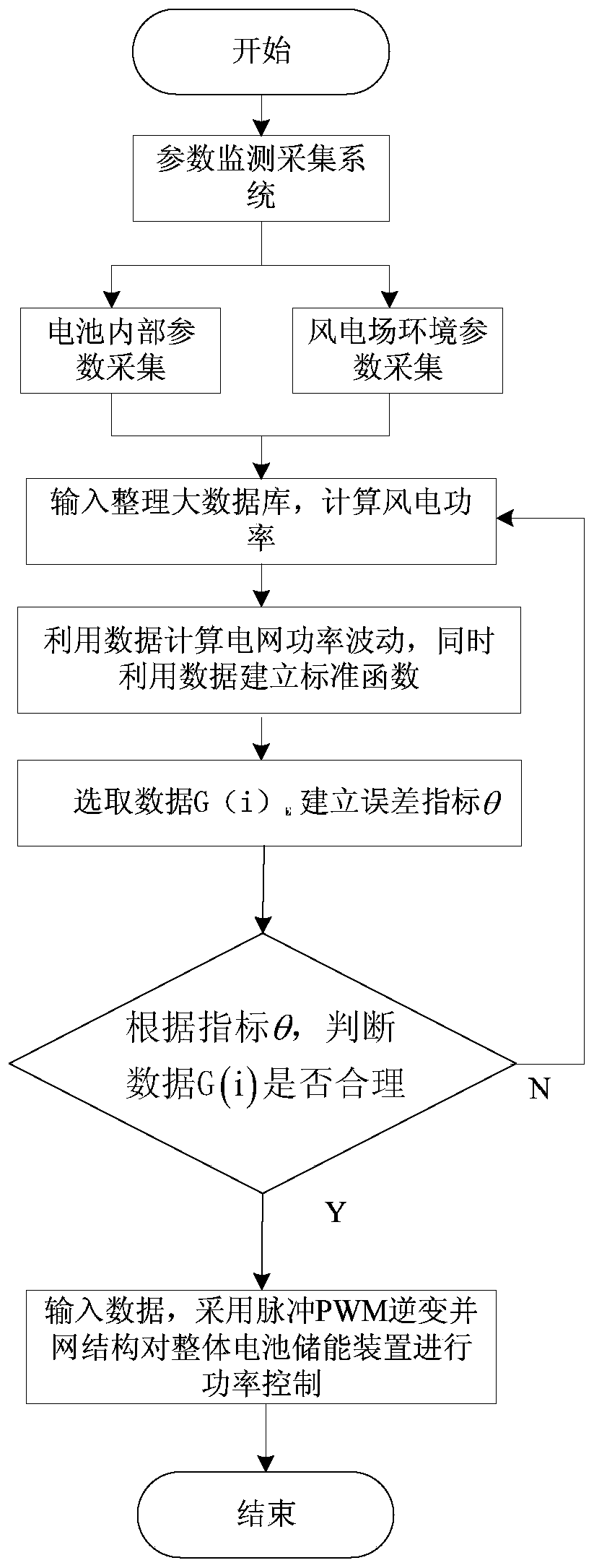

A frequency stability control method for battery energy storage grid based on big data

ActiveCN111030140BThe calculation result is accurateStable control frequencySingle network parallel feeding arrangementsEnergy storageControl engineeringPower grid

The invention discloses a method for controlling the frequency stability of a battery energy storage power grid based on big data, which belongs to the technical field of power grid stability control. The method comprehensively considers temperature, humidity and other influencing factors when calculating power, so that the calculation result is more accurate. Design a standard function about the battery temperature in the selection of temperature, choose the temperature under reasonable and normal working conditions, reduce the error of the whole device control caused by the temperature error, and choose the PWM inverter structure to control the battery energy storage device Grid-connected, through the control of the combination of active and reactive power of battery energy storage, the control of the system has a certain degree of self-adaptation.

Owner:国网内蒙古东部电力有限公司经济技术研究院 +3

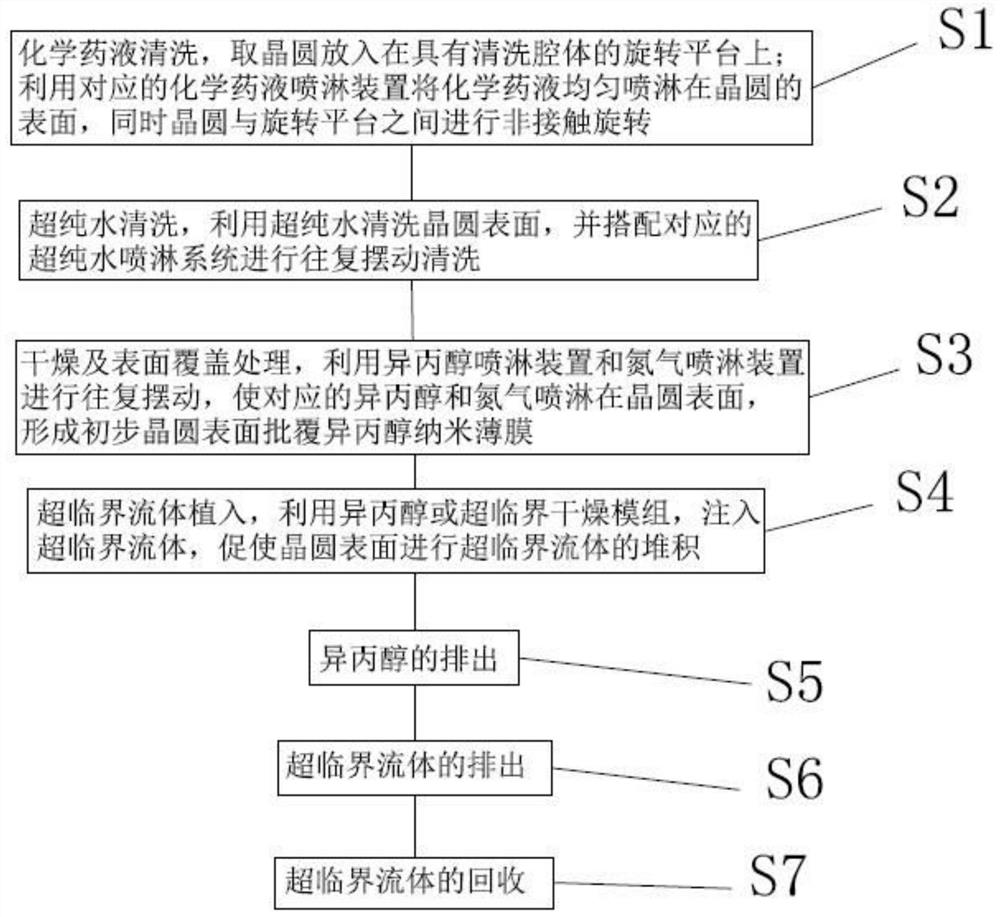

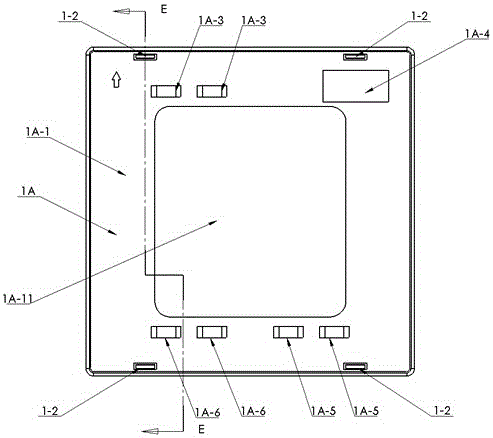

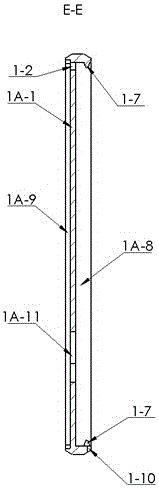

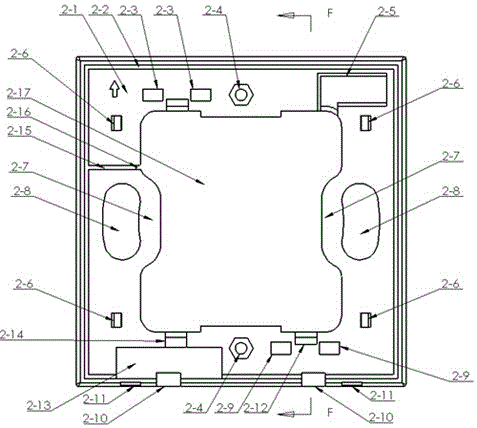

Sti cleaning process suitable for novel storage structure

PendingCN114038735AEfficient exclusionAchieve stability controlSemiconductor/solid-state device manufacturingWaferSilicon oxide

The invention discloses a Sti cleaning process suitable for a novel storage structure, and relates to the technical field of semiconductor manufacturing, and the Sti cleaning process comprises the operation steps of chemical liquid cleaning, ultrapure water cleaning, drying and surface covering treatment, supercritical fluid implantation, isopropanol discharge, supercritical fluid discharge, supercritical fluid recovery and the like. Thus, the surface of a wafer can be cleaned and dried, silicon oxide on the surface of the wafer can be taken out, and the phenomenon of tension drawing graphical collapse of water molecules and isopropanol molecules on the surface of the wafer is avoided.

Owner:ULTRON SEMICON (SHANGHAI) CO LTD

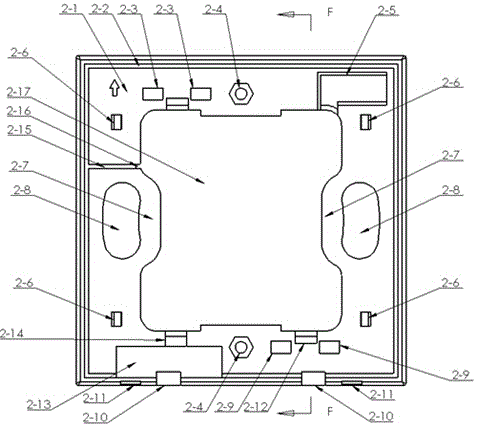

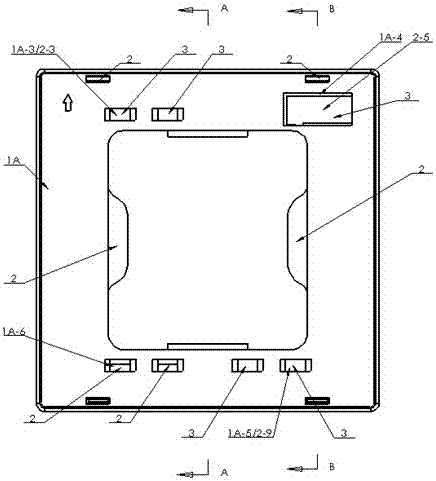

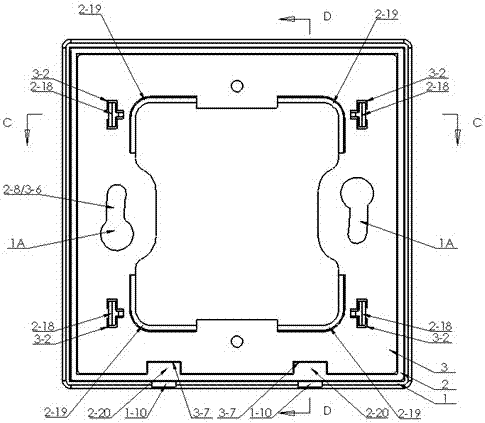

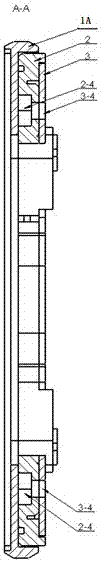

Design method for general structural parts of building block combined intelligent electrical appliances

ActiveCN104934820BReduce in quantityReduce typesCoupling contact membersCouplings bases/casesState of artWorkload

Owner:辽宁厚嘉科技有限公司

A method for avoiding coiling scratches on the surface of hot continuous rolling stainless steel strip

ActiveCN106311756BIdentify the phenomenon of inconsistency in up and down speedSolve the problem of surface abrasionRoll mill control devicesMetal rolling arrangementsStrip steelContinuous rolling

The invention relates to the technical field of hot continuous rolling, in particular to a method for avoiding reeling and scratching of a hot continuous rolling stainless steel strip steel surface. The method for avoiding reeling and scratching of the hot continuous rolling stainless steel strip steel surface comprises the steps that the difference value between the actual speed of an upper pinch roll and the actual speed of a lower pinch roll is calculated, and if the absolute value of the difference value is larger than or equal to 0.5m / s, it shows that the speed difference exists in strip steel, and the stainless steel surface is scratched. The method has the beneficial effects that the phenomenon that in the reeling process, the up and down speeds of the pinch rolls are inconsistent is identified, through adjustment of pressure control parameters of the pinch rolls, the problem that in the reeling process of the hot continuous rolling stainless steel strip steel, the surface is scratched is solved, the strip steel product quality is ensured, and stable control over a hot continuous rolling reeling machine is achieved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

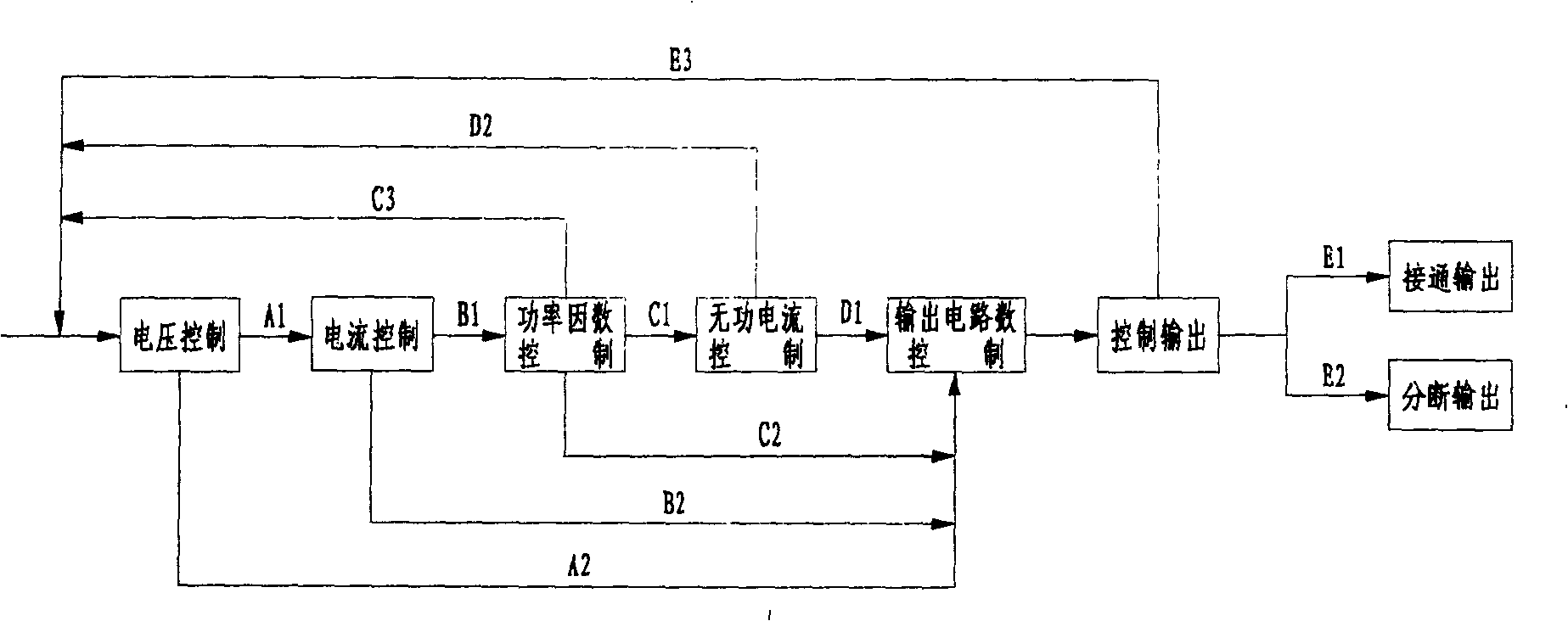

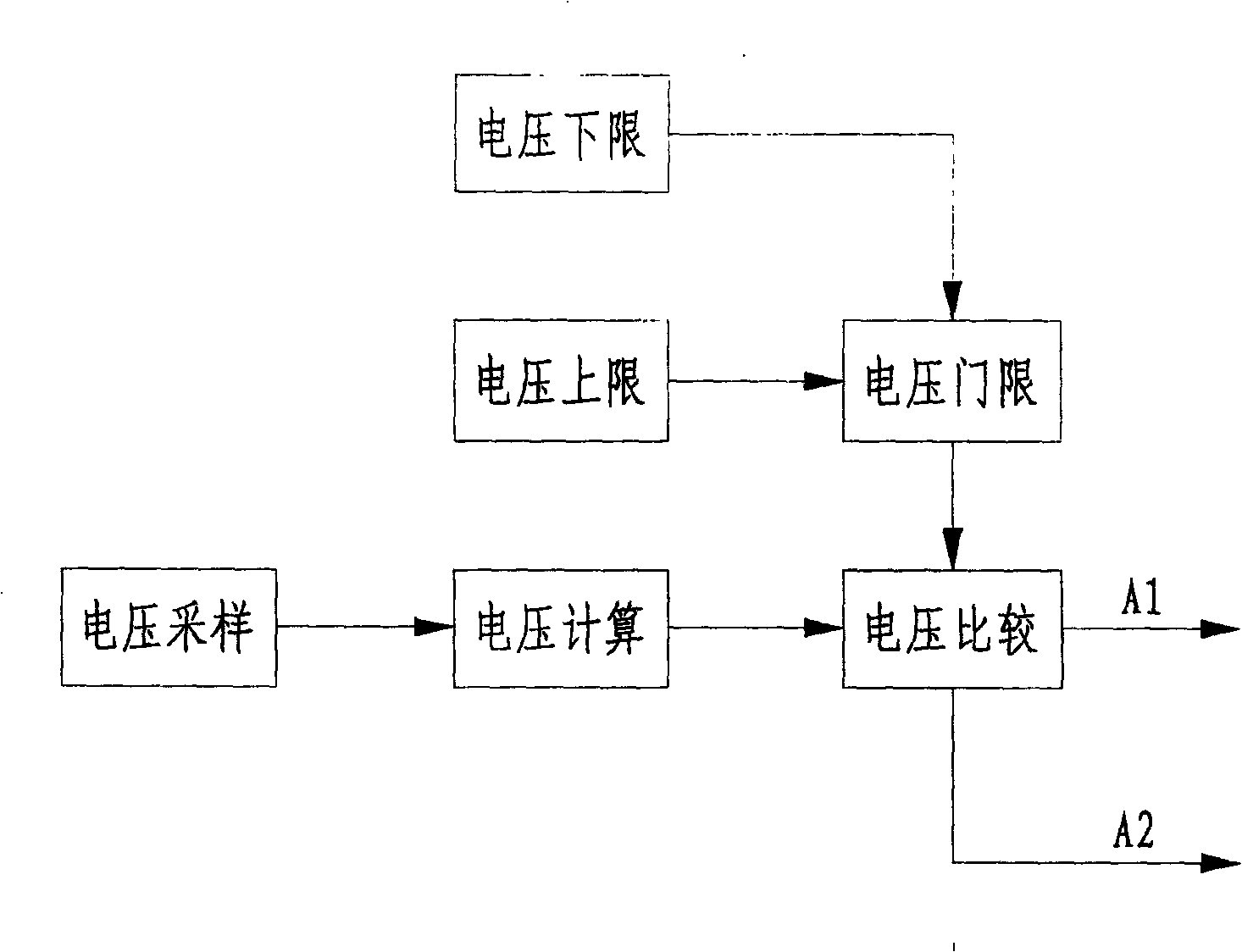

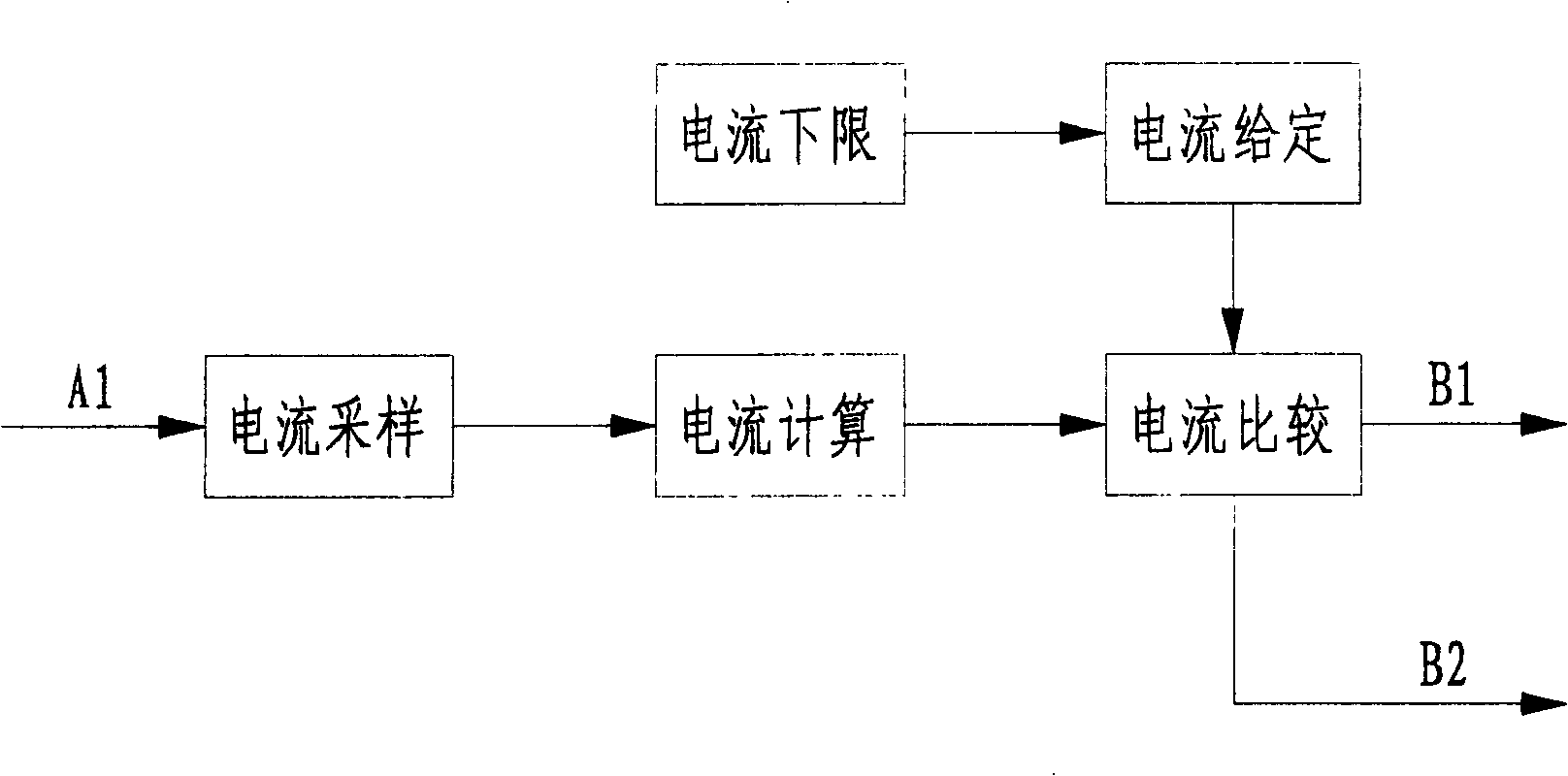

Power-less compensation control method

ActiveCN100438256CEnsure normal working voltageAvoid switching oscillationsReactive power adjustment/elimination/compensationReactive power compensationLoop controlPower factor control

The control method uses voltage as first controlled variable, current as second controlled variable, power factor as third controlled variable, reactive current as fourth controlled variable, number of loop as fifth controlled variable. Comparing voltage, current, power factor, reactive current, and number of loop with their threshold values setup in advance, the method carries out voltage control, current control, power factor control, reactive current control, and number of loop control in sequence. Whole procedure is a large circulation. Based on ever changing parameter such as voltage, current, power factor, reactive current, and number of loop of product, the method does corresponding handling to implement synthetical and stable control.

Owner:DELIXI GROUP INSTRUMENT CO LTD

Zero adjusting horizontal method for pinch roll of hot continuous rolling mill recoiling machine

ActiveCN103272886AEliminate problems such as poor roll shapeAchieve stability controlMetal working apparatusSystem pressureCavity pressure

The invention belongs to the field of hot continuous rolling machinery, and particularly relates to a zero adjusting horizontal method for a pinch roll of a hot continuous rolling mill recoiling machine. According to the technical scheme, the zero adjusting horizontal method for the pinch roll of the hot continuous rolling mill recoiling machine is characterized in that pressure sensors are installed on a transmission side and an operation side of the pinch roll of the hot continuous rolling mill recoiling machine; after the pinch roll is raised quickly, namely the pinch roll is in the maximum position, the values of the pressure sensors on both sides are right, namely a rodless cavity pressure is a system pressure and a rod cavity pressure is zero, but if the pressures are not right, examination and determination are needed, and a hydraulic system is examined or the pressure sensors are replaced according to specific practical conditions; and after the pinch roll is raised quickly, namely the pinch roll is in the maximum position, if the values of the sensors at both sides are different but not the same, an eccentric pin needs to be adjusted anticlockwise or clockwise till the values are the same. The method has the beneficial effects of solving the problem that long-term adjustment is needed after a pinch roll of an existing hot continuous rolling mill recoiling machine is replaced, solving the problem of bad coiling shape caused by a non-horizontal zero adjusting position after the pinch roll during hot continuous rolling is replaced, ensuring the quality of band steel products and realizing stable control of the hot continuous rolling mill recoiling machine.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

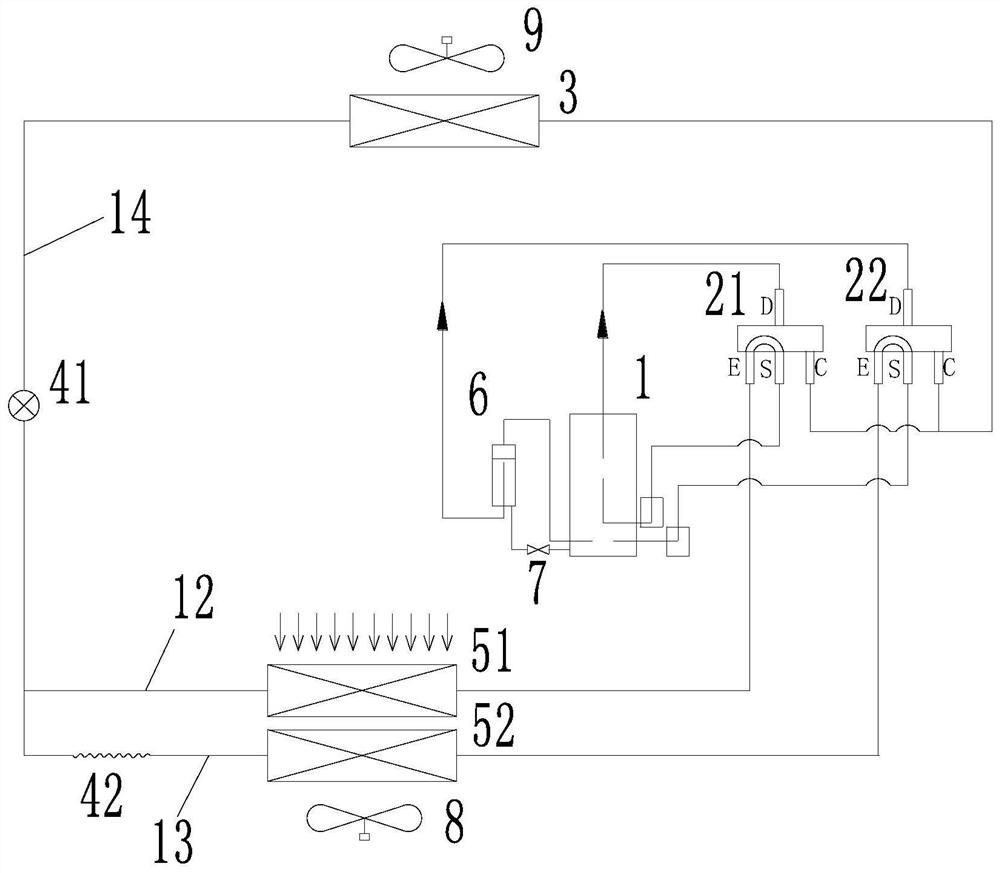

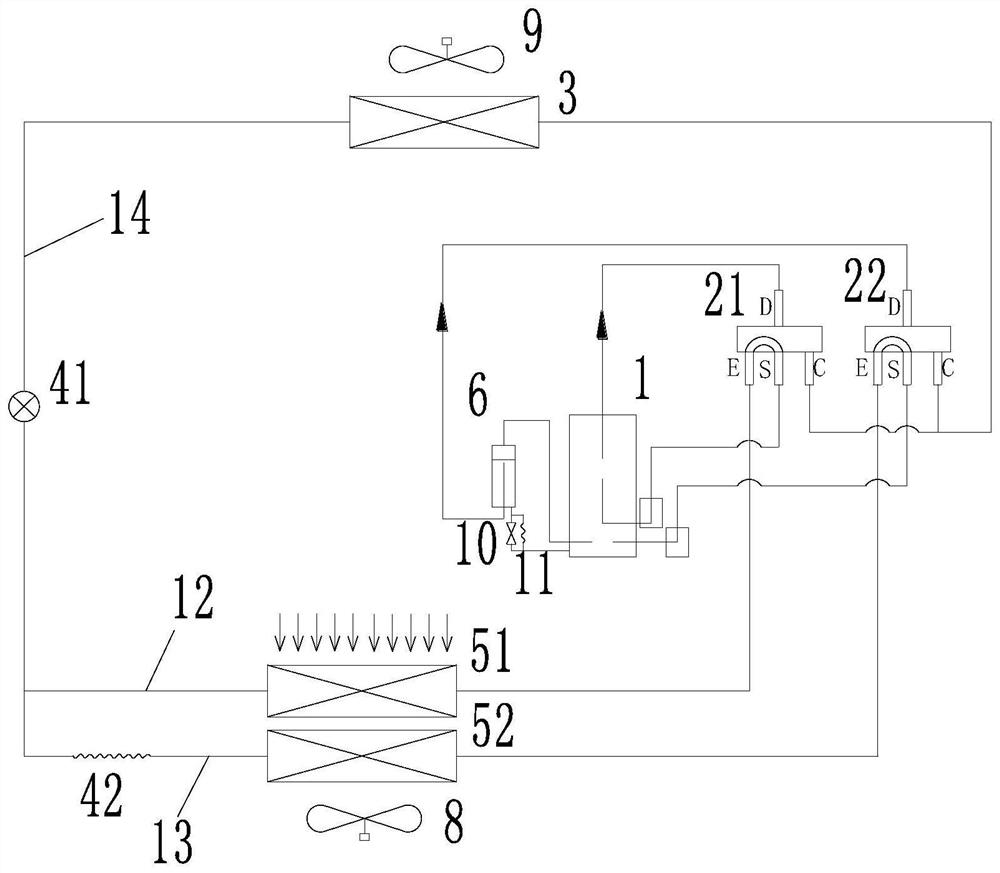

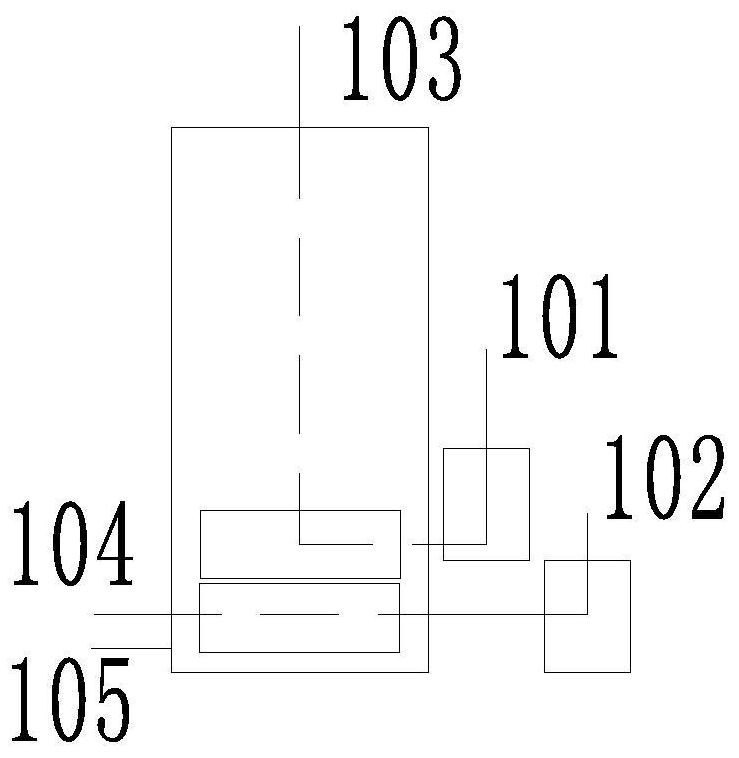

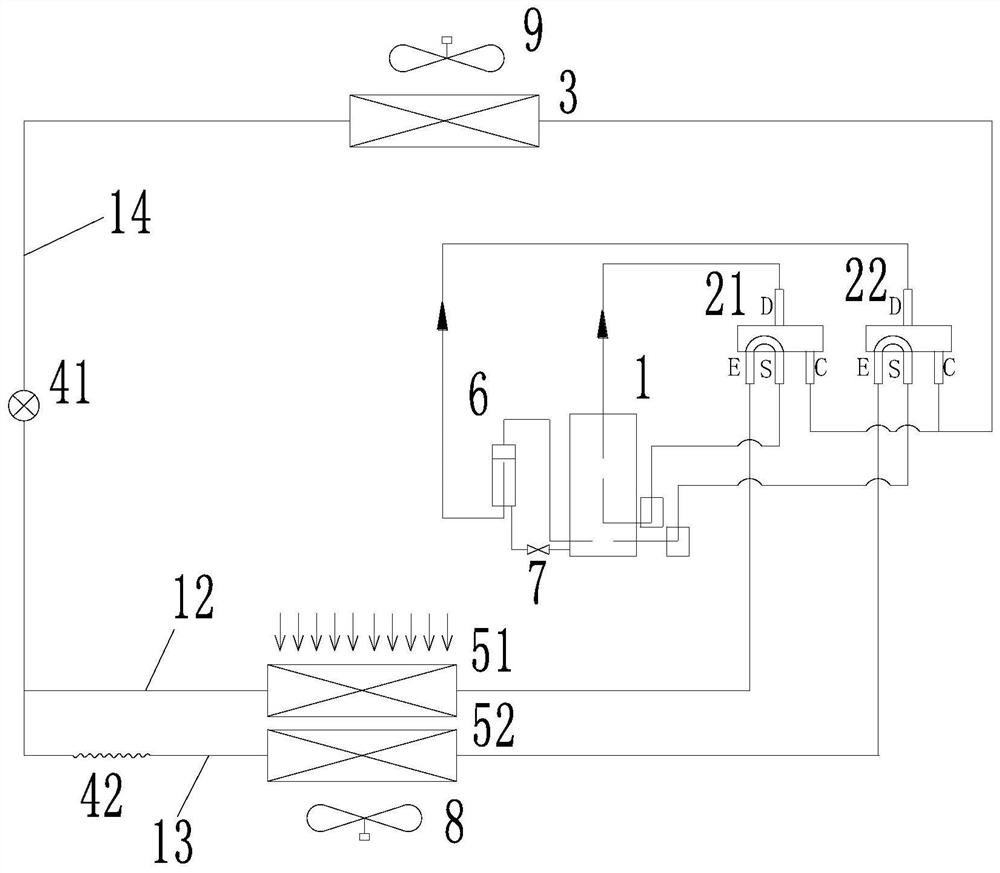

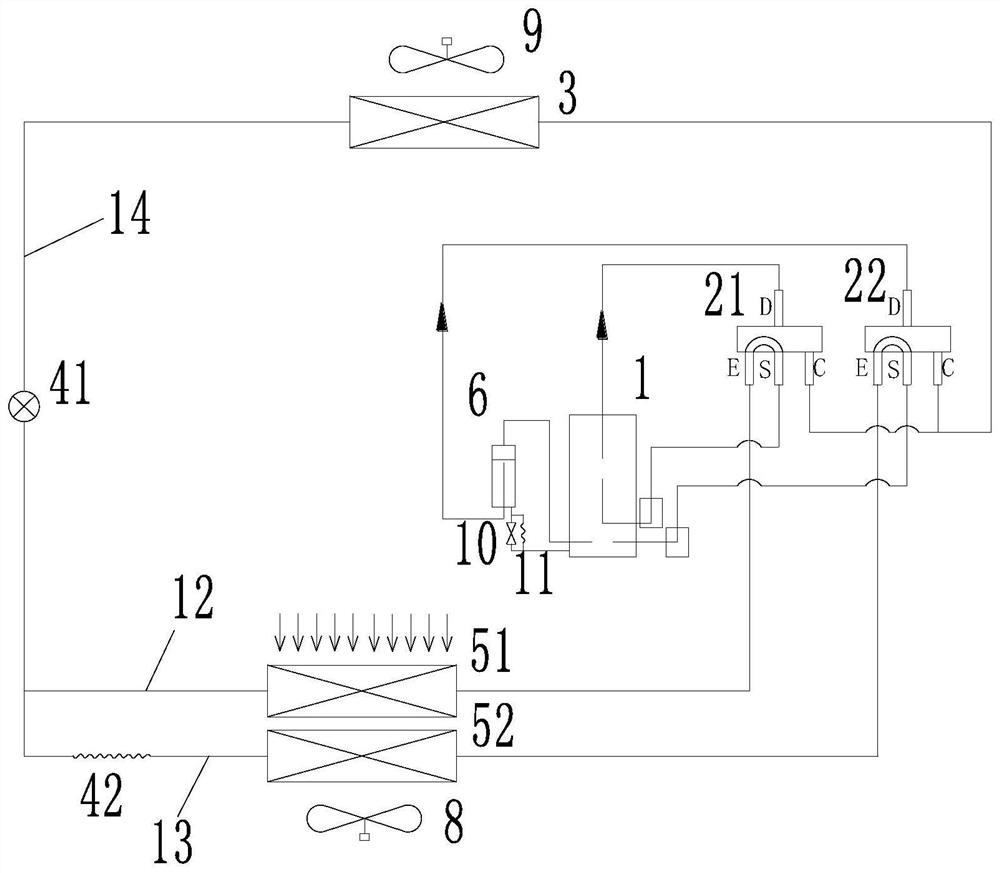

Dual-temperature air conditioning system, control method and air conditioner

ActiveCN111609588AAchieve stability controlGuaranteed uptimeCompressorMechanical apparatusAir conditioningPhysics

The application provides a dual-temperature air conditioning system, a control method and an air conditioner. The dual-temperature air conditioning system comprises a compressor, an outdoor heat exchanger, a first indoor heat exchanger and a second indoor heat exchanger, wherein after confluence, a first pipeline and a second pipeline communicate with the outdoor heat exchanger through a third pipeline; a first throttling device is arranged on the third pipeline; a second throttling device is arranged on the second pipeline; and the opening of the second throttling device is fixed; corresponding opening benchmark and opening upper and lower limits of the opening of the first throttling device can be selected from a preset throttling device opening figure, and is controlled according to first exhaust temperature or second exhaust temperature of the compressor, or is controlled and adjusted according to the third exhaust temperature of a third exhaust opening. According to the dual-temperature air conditioning system disclosed by the invention, the stable control of the two throttling devices in the dual-temperature air conditioning system can be realized, so that the dual-temperature air conditioning system is guaranteed to stably, reliably and efficiently run.

Owner:GREE ELECTRIC APPLIANCES INC

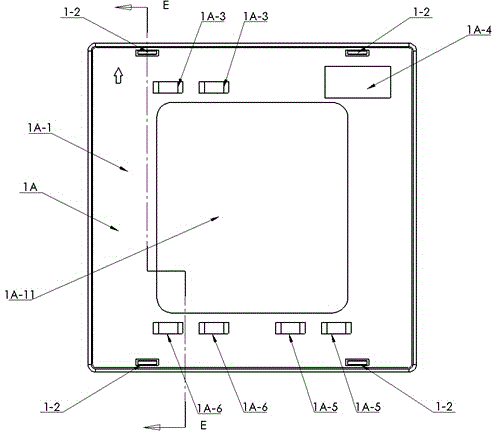

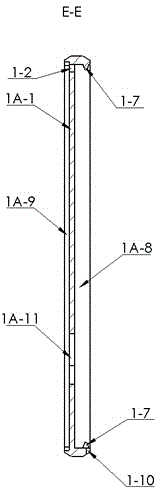

Design method for intelligent electric appliance general structural member of building block combination type

ActiveCN104934820AReduce in quantityReduce typesCoupling contact membersCouplings bases/casesWorkloadDesign methods

The invention discloses a design method for an intelligent electric appliance general structural member of a building block combination type, and irons out a defect that poor universality of parts of switch socket electric appliance products in the prior art causes tedious and burdensome design tasks for various types of products and the increase of types of dies and earlier investment of products. The method is characterized in that the method comprises the steps: general structural member planning, general structural member design, and product design; the general structural member design comprises the design of a first panel outer frame, a second panel outer frame, an upper lining plate and a metal lining plate, enabling the general structural member to be combined and matched with other parts in a mode of building block combination, building an electric appliance switch, an electric appliance socket or a scene controller product, which are of different types and have different functions; the beneficial effects are that the universality of the general structural member reaches 75%-93%, is convenient to disassemble and assemble, and is easy to assemble and adjust; the types of dies are reduced, and the production cost is reduced; the assembly process is simplified; the development cycle of products is shortened; and the machining workload is increased.

Owner:辽宁厚嘉科技有限公司

Method for avoiding reeling and scratching of hot continuous rolling stainless steel strip steel surface

ActiveCN106311756AIdentify the phenomenon of inconsistency in up and down speedSolve the problem of surface abrasionRoll mill control devicesMetal rolling arrangementsStrip steelContinuous rolling

The invention relates to the technical field of hot continuous rolling, in particular to a method for avoiding reeling and scratching of a hot continuous rolling stainless steel strip steel surface. The method for avoiding reeling and scratching of the hot continuous rolling stainless steel strip steel surface comprises the steps that the difference value between the actual speed of an upper pinch roll and the actual speed of a lower pinch roll is calculated, and if the absolute value of the difference value is larger than or equal to 0.5m / s, it shows that the speed difference exists in strip steel, and the stainless steel surface is scratched. The method has the beneficial effects that the phenomenon that in the reeling process, the up and down speeds of the pinch rolls are inconsistent is identified, through adjustment of pressure control parameters of the pinch rolls, the problem that in the reeling process of the hot continuous rolling stainless steel strip steel, the surface is scratched is solved, the strip steel product quality is ensured, and stable control over a hot continuous rolling reeling machine is achieved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Building block combined smart electrical appliance universal switch socket panel

ActiveCN104918429BReduce typesEasy to assemble and disassembleCasings/cabinets/drawers detailsRack/frame constructionState of artEngineering

The general switch socket panel of the building block combined smart electrical appliances overcomes the lack of versatility of the components of the switch socket electrical products in the prior art, which brings heavy design tasks to the demand for multi-variety products, and increases the types of molds and the initial investment in products The problem of cost is characterized in that the second panel outer frame is provided with the first molding process hole, the first buckle and the first outer frame groove with the same structure as the first panel outer frame, the first panel outer frame, the second panel outer frame The outer frame of the second panel is provided with the same rectangular central cavity as the upper liner and the metal liner, and the first buckle and the buckle groove of the upper liner are passed between the first panel outer frame or the second panel outer frame and the upper liner The beneficial effect of the connection is that the common structural parts are designed with the same structure, and the products have the same elements, which is not only convenient for disassembly and assembly, but also easy for assembly and adjustment, which reduces the types of molds, reduces production costs, and simplifies the process of assembly. The product development cycle is shortened, and the processing workload is reduced.

Owner:辽宁厚嘉科技有限公司

Zero adjusting horizontal method for pinch roll of hot continuous rolling mill recoiling machine

ActiveCN103272886BEliminate problems such as poor roll shapeAchieve stability controlMetal working apparatusSystem pressureCavity pressure

The invention belongs to the field of hot continuous rolling machinery, and particularly relates to a zero adjusting horizontal method for a pinch roll of a hot continuous rolling mill recoiling machine. According to the technical scheme, the zero adjusting horizontal method for the pinch roll of the hot continuous rolling mill recoiling machine is characterized in that pressure sensors are installed on a transmission side and an operation side of the pinch roll of the hot continuous rolling mill recoiling machine; after the pinch roll is raised quickly, namely the pinch roll is in the maximum position, the values of the pressure sensors on both sides are right, namely a rodless cavity pressure is a system pressure and a rod cavity pressure is zero, but if the pressures are not right, examination and determination are needed, and a hydraulic system is examined or the pressure sensors are replaced according to specific practical conditions; and after the pinch roll is raised quickly, namely the pinch roll is in the maximum position, if the values of the sensors at both sides are different but not the same, an eccentric pin needs to be adjusted anticlockwise or clockwise till the values are the same. The method has the beneficial effects of solving the problem that long-term adjustment is needed after a pinch roll of an existing hot continuous rolling mill recoiling machine is replaced, solving the problem of bad coiling shape caused by a non-horizontal zero adjusting position after the pinch roll during hot continuous rolling is replaced, ensuring the quality of band steel products and realizing stable control of the hot continuous rolling mill recoiling machine.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

A method for improving the cleanliness of steel containing nb and ti

The invention provides a method for improving cleanness of Nb-Ti containing steel. The method comprises the following steps of: smelting in a top-bottom combined blowing converter under the condition of argon gas bottom-blowing in the whole process; adding small-grain limes and fluorite in a steel tapping process; adding slow-release deoxidizing agent to the top of the slag after the steel tapping; carrying out secondary refining onto molten steel; feeding the refined molten steel to a continuous casting process for carrying out full-protection casting. According to the invention, low-nitrogen molten steel is obtained by adopting an argon gas bottom-blowing mode in the whole converter smelting process, calcium treatment and soft blowing are performed after LF (Low Frequency) furnace refining desulfuration and heating up, Nb-Ti alloying is carried out and the alloy melting is promoted by carrying out soft blowing again. Moreover, oxide impurities can be reduced by calcium pre-treatment and a soft-blowing process, the Nb-Ti alloy is promoted to melt by the soft blowing, impurities are removed by RH (Ruhrstahl Heraeus) vacuum refining and degassing, impurities are further removed by carrying out soft blowing after breaking the vacuum, and casting blank segregation can be weakened by continuous casting and low-superheat-degree casting, so that the purpose of controlling the oxide impurities and the nitride impurities in the steel is achieved.

Owner:SHOUGANG CORPORATION

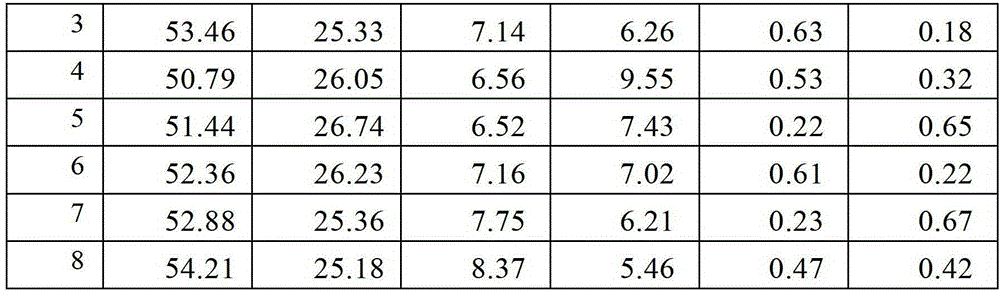

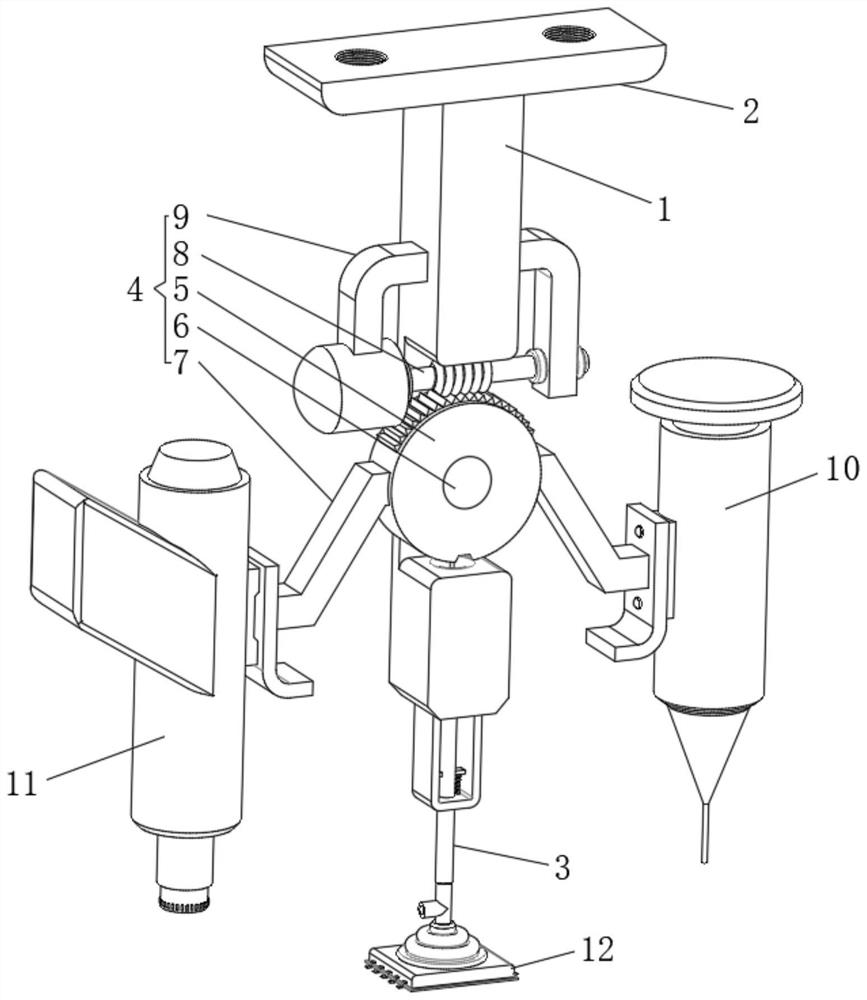

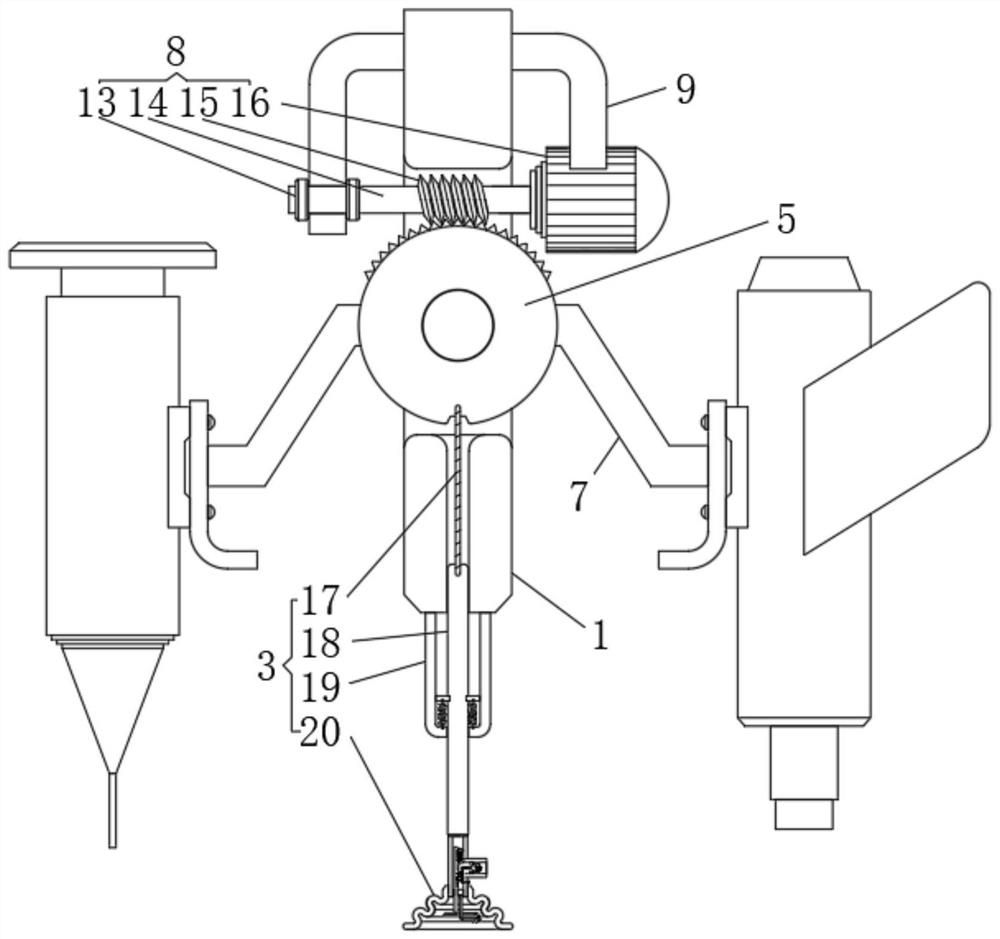

Welding system for solder paste packaging of electronic connector

PendingCN114256711ARealize automatic controlStable controlPrinted circuit assemblingLine/current collector detailsPhysicsAutomatic control

The invention relates to the technical field of solder paste welding, in particular to a welding system for solder paste packaging of an electronic connector, which comprises a middle column, a top plate is fixed at the top end of the middle column, a control lifting frame is connected to the bottom end of the middle column, a square hole is formed in the middle of the middle column, and a swing assembly is arranged in the square hole. The swing assembly comprises a control cylinder, a center shaft, supporting frames, a brake device and an outer plate frame, the center shaft is movably sleeved with the middle of the control cylinder, the end of the center shaft is fixed to the center column, and the supporting frames are fixed to the two sides of the control cylinder; according to the structural design, solder paste smearing work of a paste injection gun, sticking work of a connector element and heating and blowing work of a hot air gun are carried out in a segmented mode, the three control working mechanisms are separated from one another, and mutual influence of work caused by too close work is avoided; and when one working mechanism works, the other two working mechanisms can be separated from each other, so that automatic control is realized.

Owner:SHENZHEN HANGLIANTONG CONNECTOR TECH CO LTD

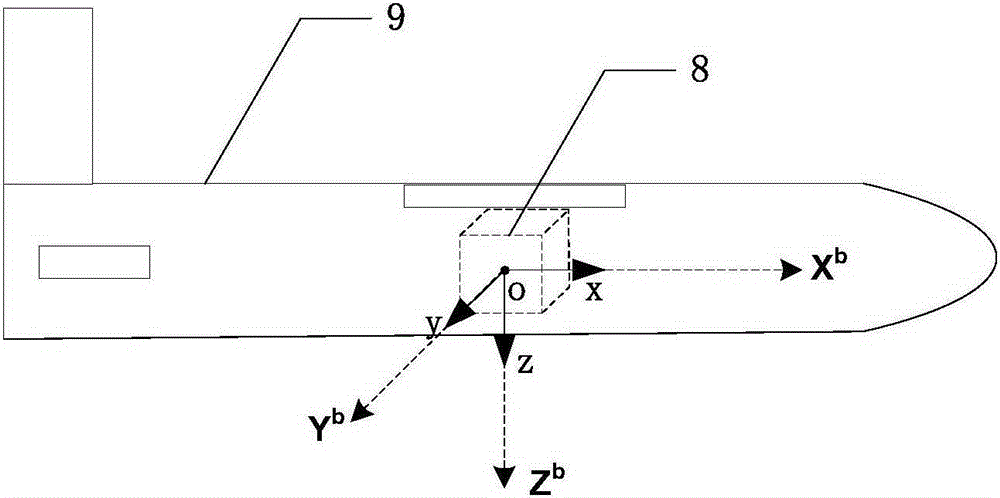

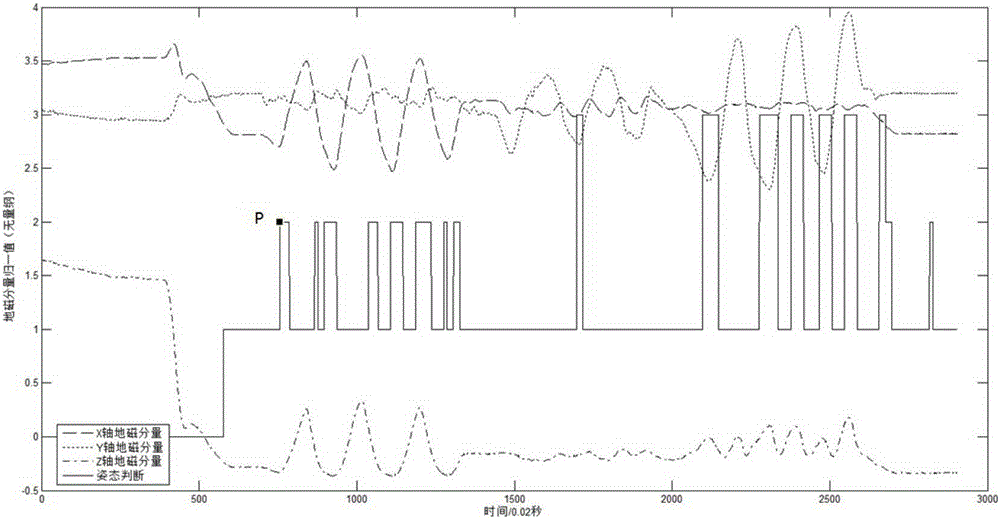

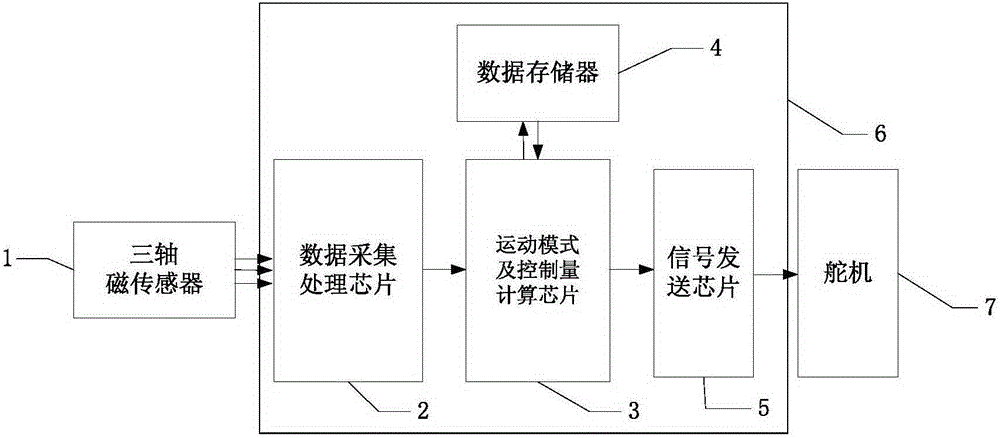

A stability control method and system for a parachute-type small unmanned aerial vehicle

ActiveCN103728880BSolving Stability Control IssuesAchieve stability controlAttitude controlAdaptive controlBody axisGyroscope

The invention discloses a parachuting-type small unmanned aerial vehicle stable control method and system. Geomagnetic elements of a geomagnetic field on the X axis, the Y axis and the Z axis of a body axis system of an unmanned aerial vehicle are measured by means of a three-axis magnetic sensor, and a steering engine which needs to be controlled and control quantities are determined according to changes of the measured geomagnetic elements. The method is simple and easy to carry out, the problem that real-time posture information cannot be obtained after the unmanned aerial vehicle dives and hikes and a global positioning system and a gyroscope cannot work normally is solved, and stable control of the unmanned aerial vehicle can be automatically finished.

Owner:湖北凯龙国安防务科技有限公司

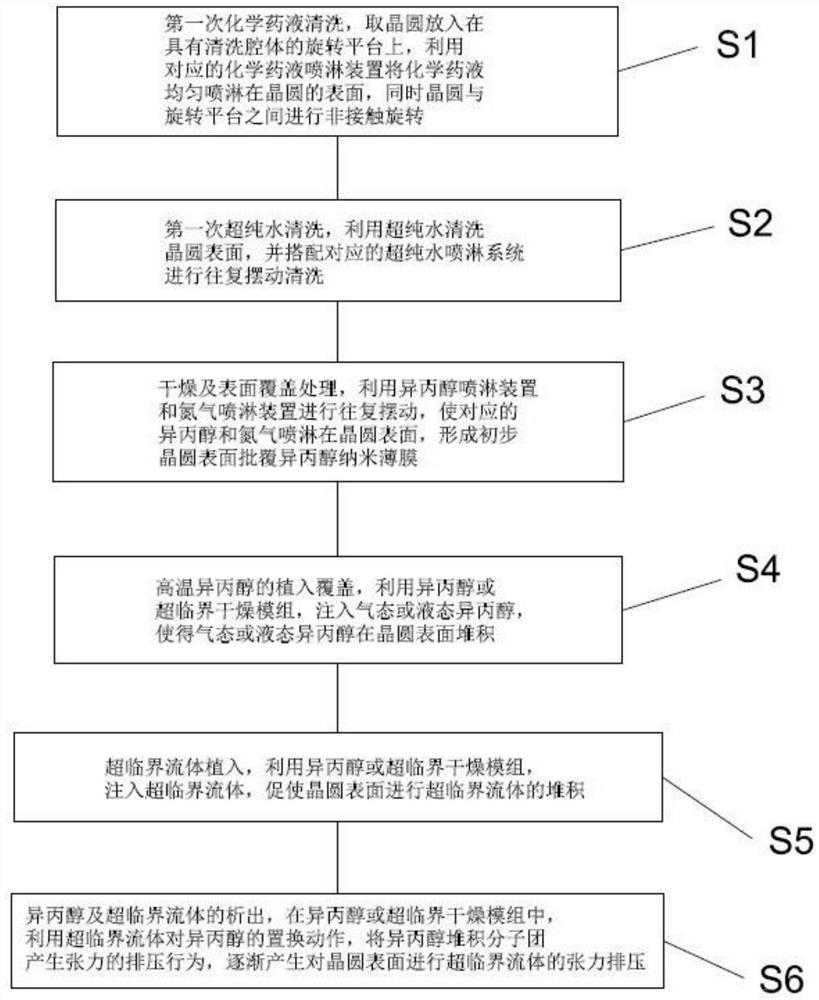

Cleaning process for solving patterning collapse of advanced node

PendingCN114038734AEfficient removalAchieve stability controlSemiconductor/solid-state device manufacturingChemical solutionWafer

The invention discloses a cleaning process for solving patterning collapse of an advanced node, and relates to the technical field of semiconductor manufacturing. The cleaning process comprises the operation steps of first-time chemical solution cleaning, first-time ultrapure water cleaning, drying and surface covering treatment, high-temperature isopropanol implantation covering, supercritical fluid implantation, isopropanol and supercritical fluid precipitation and the like. Isopropanol molecules carrying water molecules can be removed from the surface of the wafer, so that the stability of the surface property of the wafer treated by a wet process is controlled, and the phenomenon of tension drawing graphical collapse of the water molecules and the isopropanol molecules on the surface of the wafer is avoided.

Owner:ULTRON SEMICON (SHANGHAI) CO LTD

A dual-temperature air-conditioning system, control method, and air conditioner

ActiveCN111609588BAchieve stability controlGuaranteed uptimeCompressorMechanical apparatusEngineeringAir conditioning

The present application provides a dual-temperature air-conditioning system, a control method, and an air conditioner. The dual-temperature air-conditioning system includes: a compressor, an outdoor heat exchanger, a first indoor heat exchanger and a second indoor heat exchanger; the first pipeline and the second pipeline are connected to the outdoor heat exchange through the third pipeline device, a first throttling device is set on the third pipeline, and a second throttling device is set on the second pipeline; the opening degree of the second throttling device is fixed, and the opening degree of the first throttling device can be changed from the preset Select the corresponding opening reference and opening upper and lower limits from the opening table of the throttling device, and control and adjust according to the first exhaust temperature or the second exhaust temperature of the compressor; or, according to the third row of the compressor The third exhaust gas temperature at the air port is controlled and adjusted. According to the present application, the stable control of the two throttling devices in the dual-temperature air-conditioning system can be realized, and the stable, reliable and efficient operation of the dual-temperature air-conditioning system can be ensured.

Owner:GREE ELECTRIC APPLIANCES INC

Battery energy storage power grid frequency stability control method based on big data

ActiveCN111030140AThe calculation result is accurateStable control frequencySingle network parallel feeding arrangementsEnergy storageControl engineeringPower grid

The invention discloses a battery energy storage power grid frequency stability control method based on big data. The invention belongs to the technical field of power grid stability control. According to the method, influence factors such as temperature and humidity are comprehensively considered during power calculation; the calculation result is more accurate; a standard function related to thebattery temperature is designed for temperature selection; the temperature under the reasonable and normal working condition is selected, errors, caused by temperature errors, of the control over a whole device are reduced, a PWM inversion structure is selected to conduct grid connection on a battery energy storage device, and through active and reactive combined control over battery energy storage, the control over the system has certain self-adaptation.

Owner:国网内蒙古东部电力有限公司经济技术研究院 +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com