Method and system for stabilizing processing strength of drum-type cut-tobacco dryer

A silk drying machine and drum-type technology, which is applied in the field of stable processing strength of the drum-type silk drying machine, can solve the problems of control lag, poor real-time control ability of batch process, and many influencing factors, so as to achieve stable control and stable batch-to-batch The effect of processing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In a typical implementation of the present application, a method for stabilizing the processing strength of a drum-type silk drying machine is disclosed, and the mathematical model used is:

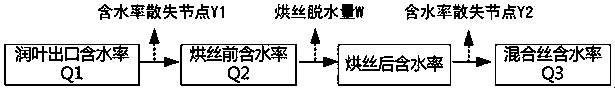

[0037] The water loss model of each section before and after the water, Y1=X1-X2×Z+X3×N1+X4×N2, Y2=X5+X6×N3-X7×N4, where; Y1 is the water loss from the exit of moistening leaves to the entrance of drying shreds , Y2 is the water loss from the drying silk outlet to the mixed silk section, Z is the leaf storage time after moistening the leaves, N1 is the water loss point Y1 ambient temperature, N2 is the water loss point Y1 ambient humidity, N3 is the water loss point Y2 ambient temperature, N4 is the water loss point Y2 ambient humidity, X1, X2, X3, X4, X5, X6, and X7 are brand coefficient constants, which can be set according to the situation of the previous month or the same period of the previous year. The actual value of the moisture content of all batches of cigarettes of the c...

Embodiment 2

[0041] A system for stabilizing the processing strength of a drum-type silk drying machine, including a dynamic prediction system for the processing strength of silk drying. The dynamic prediction system for the processing strength of silk drying communicates with a measurement system and a production central control system. The measurement system is an environment temperature and humidity acquisition module and Historical data analysis module;

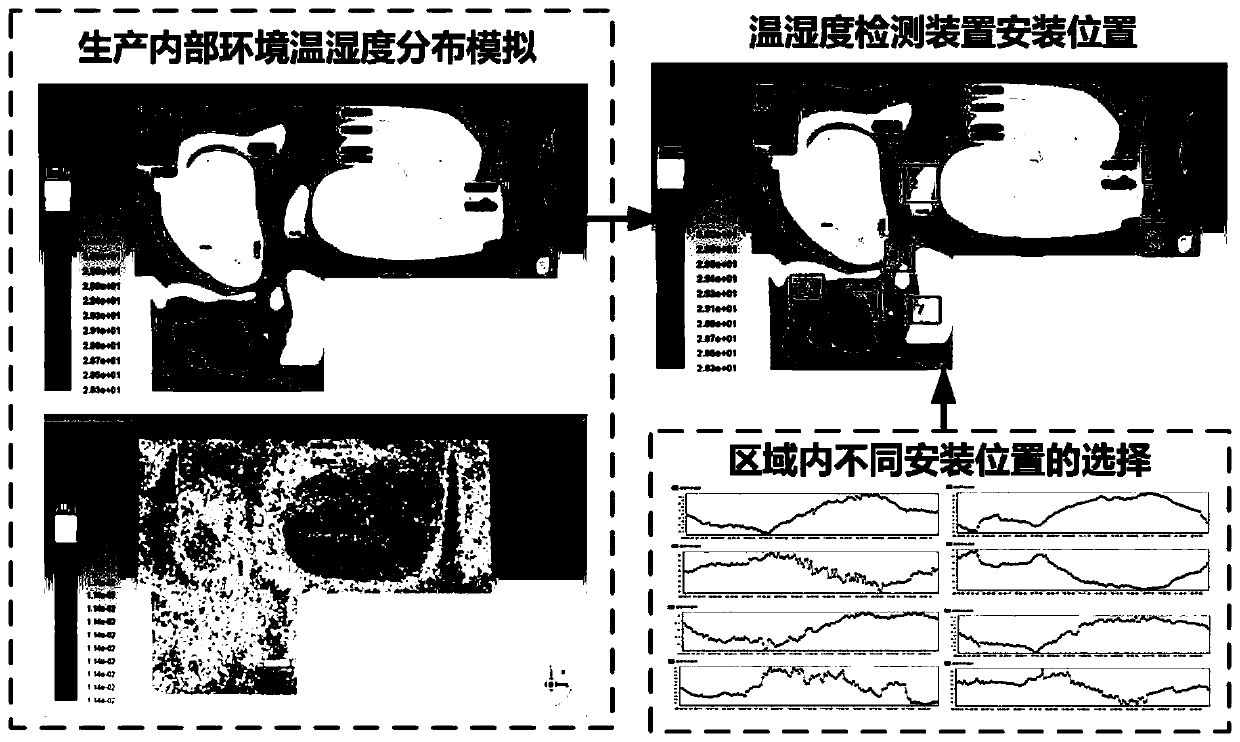

[0042]Further, the ambient temperature and humidity acquisition module simulates the distribution of the ambient temperature and humidity inside the production workshop, preferably at a height of 1.5±0.3m as the installation plane, and selects a process route that can characterize the temperature and humidity changes in this area in combination with the process route where the moisture content is lost. The area is the installation point, and finally through the data fusion of the dynamic prediction system of the drying processing inten...

Embodiment 3

[0046] Taking a certain brand of cigarettes as an example, the analysis is carried out in units of historical months. Collect the water loss value of all batches from November 1st to 30th, 2017 and the environmental temperature and humidity value of the water loss point, and perform regression analysis to determine the mathematical model, Y1=-0.365-0.006*leaf storage time+0.059*internal temperature -0.006*internal humidity; Y2=1.192+0.005*internal temperature-0.012*internal humidity.

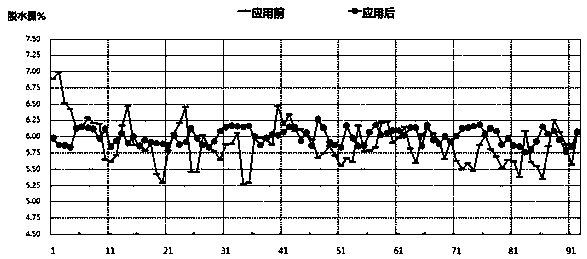

[0047] After the validity test of the model, the water loss regression model is significant, and the residual and mean square tests are normal. Finally, the regression equation of the water loss point in November 2018 is obtained, and the regression equation is used to predict and control the moisture at the outlet of the leaves:

[0048] Moisture content Q1 at the outlet of moistening leaves = standard central value of moisture content of mixed silk Q3 + Y2 + brand drying dehydration target val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com