Building block combined smart electrical appliance universal switch socket panel

A technology of smart electrical appliances and socket panels, applied in the direction of electrical components, electrical equipment shells/cabinets/drawers, racks/frame structures, etc., can solve the problem of inability to meet the design requirements of image consistency and shared parts, increase input costs and management Difficulty, the switch panel is not universal, etc., to achieve the effect of shortening the development cycle, simplifying the process assembly process, and reducing the processing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

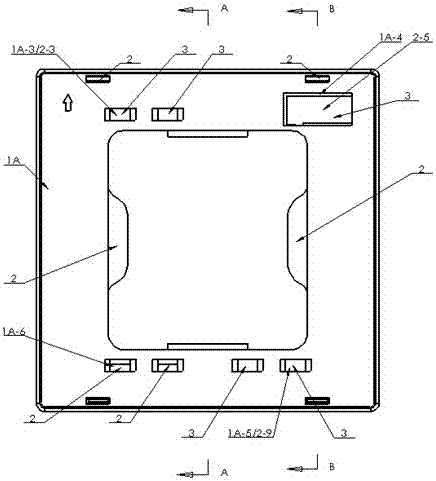

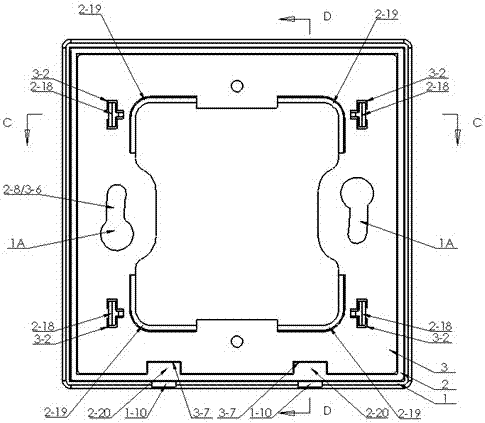

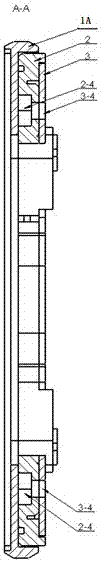

[0061] Such as Figure 1 to Figure 13 As shown, the technical solution adopted by the present invention includes a first panel outer frame 1A, an upper liner 2 and a metal liner 3;

[0062] Such as Figure 7 and Figure 8 As shown, the first panel outer frame 1A is molded by injection molding of plastic material, the first panel outer frame substrate 1A-1 of the first panel outer frame 1A is rectangular, and the center is a rectangular first panel central cavity 1A -11, the central cavity 1A-11 of the rectangular first panel is used as 1 to 4 concealed intelligent switches and buttons on the concealed universal switch circuit board or 10A and 16A concealed intelligent socket or concealed universal socket circuit board The position of the copper contact piece on the upper end is provided with four holes 1-2, corresponding to each first ejection process hole, on the front upper and lower ends of the first panel frame substrate 1A-1 There is a first buckle 1-7 on the back of 1...

specific Embodiment approach 2

[0074] Such as Figure 1 to Figure 6 and Figure 14 ~ Figure 16 As shown, Embodiment 2 is the same as Embodiment 1, except that the first panel outer frame 1A is replaced with the second panel outer frame 1B; the second panel outer frame 1B is molded by plastic material through injection molding, as shown in Figure 14 As shown, the second panel outer frame substrate 1B-1 of the second panel outer frame 1B is rectangular, and the center is two rectangular cavities on the left and right, the left rectangular cavity is the key passage hole 1B-2, and the right rectangular cavity is The indicator light of the scene insert is exposed through the hole 1B-3; Figure 15 As shown, the scene panel circuit board limiting groove 1B-5 is provided on the surrounding frame of the second panel outer frame substrate 1B-1 of the second panel outer frame 1B, and the second panel outer frame substrate 1B-1 There are four scene panel circuit board fixing columns 1B-4 at the inner corners of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com